Steel Concrete Block Staircase (Reinforced Masonry Staircase)

Overview

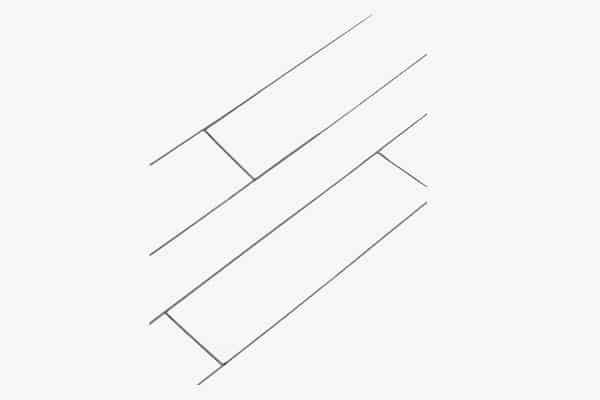

A steel-reinforced concrete block staircase, often referred to as “Steel Block Stairs,” combines concrete hollow blocks with embedded steel reinforcement to create durable and cost-effective staircase systems in buildings. This type of stair system is especially common in residential, commercial, and industrial projects for its strength and easy construction.

Advantages

- Structural Strength – Reinforced with steel bars for high load-bearing capacity.

- Fire Resistance – Concrete blocks offer high fire-retardant properties.

- Cost-Effective – Utilizes locally available materials and simple methods.

- Customizable Dimensions – Can be cast in different shapes and configurations.

- Durability – Withstands wear, weather, and impact over time.

Common Use Cases

- Internal staircases for villas and apartments

- External access stairs for buildings and warehouses

- Rooftop access stairs

- Emergency exits in commercial or public buildings

- Site-built stairs in construction zones

Technical Specifications

| Component | Typical Values |

|---|---|

| Step Width | 100 cm – 120 cm |

| Riser Height | 15 cm – 18 cm |

| Tread Depth | 30 cm – 35 cm |

| Reinforcement | Steel bars Ø 10 mm – Ø 16 mm (depending on span) |

| Concrete Block Type | Hollow or Solid Concrete Masonry Unit |

| Finish Options | Plastered, tiled, or left as raw concrete |

Installation Notes

- Always place reinforcement bars (main and stirrups) according to design.

- Ensure blocks are well-aligned and level before pouring any topping.

- Use proper bonding agents between concrete block joints.

- Apply waterproofing layer for outdoor stairs exposed to weather.

- Optional finish layers (tiles, stone, plaster) can be added for aesthetics.