50 Norman Restaurant and Shop / Schemata Architects + Jo Nagasaka

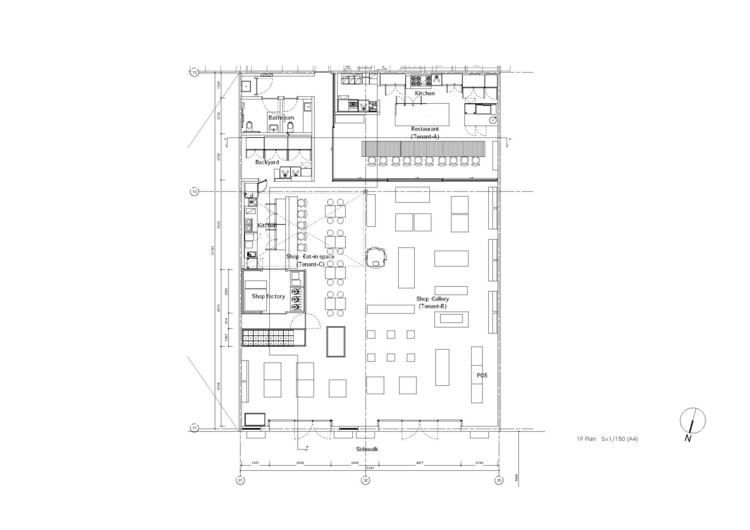

Text description provided by the architects. We designed a retail complex called “50 Norman” on Norman Ave, Brooklyn, NY. It is a Japanese food-themed retail complex consisting of “HOUSE BROOKLYN,” a Japanese French restaurant, “CIBONE,” featuring Japanese ceramics and other cooking utensils, and “Okume,” a seafood processing store established in 1871 on the Tsukiji fish market.

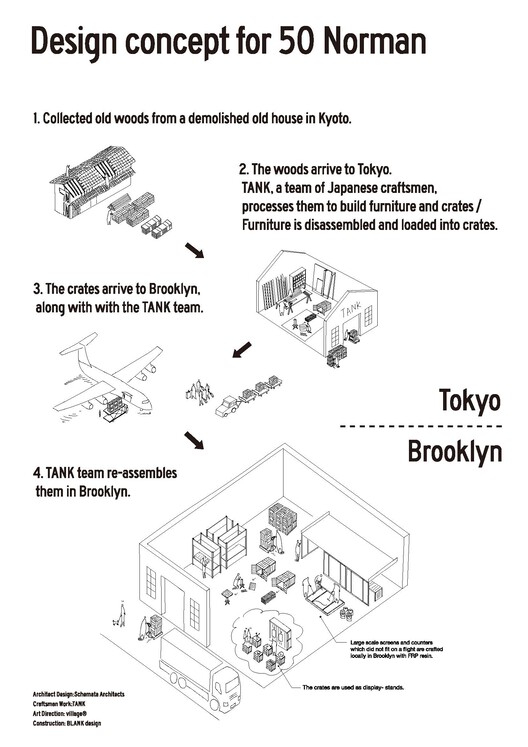

For us, this overseas store project was an away game, but we sought to uphold the quality of a home game. We had struggled to achieve what we could in Japan with our overseas projects for a long time without much success. We, at one time, thought of attempting a more simplified, easy-to-understand design that would work anywhere rather than pursuing a Japanese quality. On the other hand, we looked for a way to maintain the quality we can achieve in Japan rather than adapting our design to the locality. For this reason, we had to think about production methods to minimize costs and maintain quality.

Then, we came up with “DEKASEGI,” an idea to process materials that would otherwise be dismantled and discarded in Japan, reduce their volume as much as possible, ship them overboard, and then bring several craftsmen to the site to assemble and process them locally in a short time. Used and aged wood materials in Japan often retain their original craftsmanship, joints, and other features that give them a distinctive appearance. Our design sought to make the best use of such characteristics.

This complex was our first DEKASEGI project, and the planning began at the height of the COVID-19 crisis when many circumstances changed. One of the changes was that the shipping duration became longer and longer: what was supposed to be three months became four months, then five, and finally, unpredictable. The cost of transportation also skyrocketed accordingly. Therefore, we decided to send them by air using as little volume as possible by building crates and packing the components tightly inside them.

The idea was to use the crates as display stands for the stores and to use FRP, a resin that can be locally procured and manufactured by TANK’s artisan team yet can be adapted to the American scale. However, the air shipping cost began to soar when production began in Japan. Therefore, minimizing volume using the crate was no longer relevant. Instead, we decided to break up the components into smaller pieces and insert them into the limited space in the airplane without wasting any space. But at that point, we could no longer change our original design, so we had to disassemble the crates and insert the pieces into the gap for transportation.