There are many different types of adhesives, each with specific conditions and applications, and there are many factors to consider when choosing the right product.

Adhesives can be classified in different ways, according to their chemical composition, physical form, rating or ability to withstand loads.

In this article, we’ll discuss the different adhesive categories and how to use each.

Adhesives by chemical composition

Different adhesives can be classified by their chemistry, below are some examples of the available chemical formulations.

Epoxy adhesives

Epoxies are a type of structural adhesive, which are resistant to high temperature and solvents and can be structurally bonded to most types of materials, such as metals, ceramics, wood and plastics.

Polyurethane adhesives

Polyurethanes are polymer-based adhesives used in constructions that require high bond strength and permanent flexibility.

They are often offered as two-part adhesives and have many uses, unlike epoxy adhesives,

They require moisture to set, which means they can be used in projects where other glues are often unsuitable.

Polyurethane adhesives, such as Adbond EX 5690, can be coated to obtain a perfect finish, offer high flexibility and can be used in any weather, this makes polyurethane ideal for the transportation industry.

Polyimide adhesives

Polyimides are one-part synthetic polymers that usually contain solvents,

and are known for their strength, heat and chemical resistance,

as well as their performance at extremely high temperatures of up to 500°C.

They are offered in two formulations, thermoplastic and thermoplastic, and are often used for coatings or electronic insulation.

Adhesives in physical form

Adhesive physical form influences product application, as adhesives can be spread manually

or with tools and equipment.

Below are the different physical shapes available.

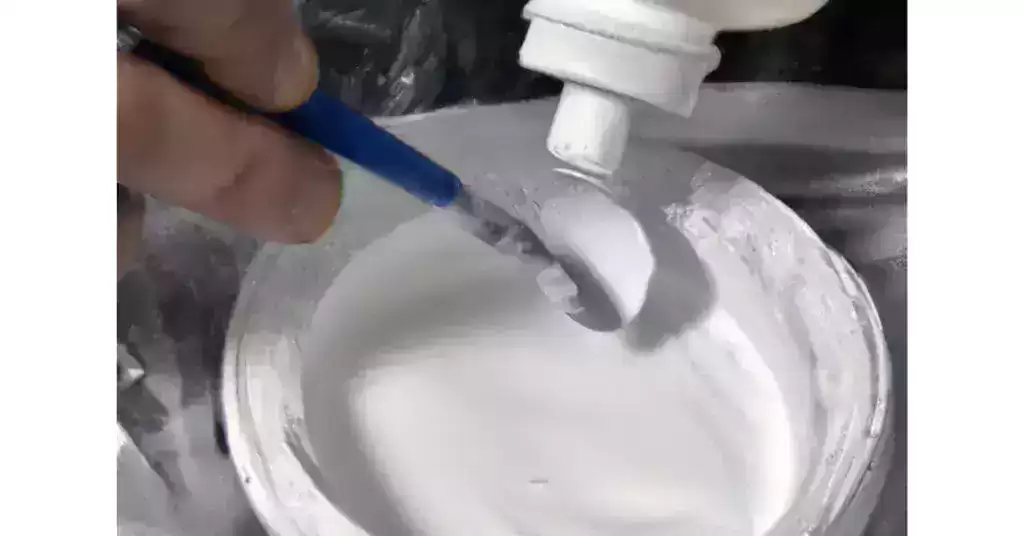

paste

Adhesive pastes are often highly viscous, making it difficult to

spread them throughout the curing period.

It is also ideal for adhesions that require space filling and is usually applied using tools such as a caulking gun.

liquid

Liquid is the most common form of adhesive and is one of the easiest to apply but can leak or sag during the curing process.

It often takes longer to cure but can be applied in thin layers to help the process.

film

Adhesive films are available in rolls or in pre-cut lengths or shapes,

offering ease of use, no restrictions on pot life,

and are available in thicknesses from 2 to 8 mm for different applications.

pellets

Adhesives are usually in the form of pellets hot melt or hot melt adhesives that usually must be inserted into a hot melt gun or melted and sprayed.

Adhesives by classification

Adhesives are also classified according to the structure

hot melt

Hot melt adhesives are brought to a thermoplastic liquid form and can be used

to coat entire surfaces before the adhesive cools to a solid polymer.

It is valued by many industrial sectors for its environmental friendliness, safety and suitability.

Different types of hot melt adhesives include EVA based, APAO and pressure sensitive adhesives.

Polyurethane hot melts are also available, but they do not have the same properties as hot melt adhesives.

Non-reactive hot melt

Unlike non-reactive hot melts, reactive hot melt adhesives generate additional chemical bonds after the hardening process.

This results in stronger adhesion once cured, extended bonding as well as higher resistance to moisture,

heat and chemicals.

Thermosetting

Thermoplastic adhesives are usually available in two part forms,

and the resin and hardener are mixed to obtain the desired setting time.

The resin and hardener can be used in one part form,

but these are not common because they must be stored at low temperatures.

Storing them at high temperatures can cause the required reaction to occur prematurely,

resulting in a greatly reduced shelf life.

pressure sensitive

Adhesives in this class of plastics have a low modulus,

which means they don’t require a lot of pressure to deform and can be used on wet surfaces.

They are also very durable for light load applications and are commonly purchased

as tapes or labels for non-structural applications.

communication

The adhesive is a flexible material and is applied to both elements bonded together,

once the solvent evaporates, the elements are placed in direct contact.

These types of adhesives are found in rubber cement or countertop chips.

For more architectural news