Construction techniques for cast-in-situ reinforced concrete pile,

The cast-in-situ pile is a kind of pile that is completely built on the project site.

The construction process includes borehole drilling,

fabrication and installation of reinforcing cages, and placement of concrete.

Certain steps of pile construction can be carried out at the same time.

The pile foundation for construction is whenever the load of the structure is large,

and the thick and weak soil layer is located below.

It is a type of deep foundation that transfers the load of the superstructure into a solid layer through weak soil layers.

Piles can be constructed at the project site or pre-poured and transported to the construction site.

Cast-on-site pile construction involves drilling a borehole,

placing a reinforcing cage and placing concrete.

Several pile construction techniques are also available,

such as Kelly rotary drilling (a type of drill pipe),

and twin rotary drilling, cast-in-situ auger for construction of cast-in-situ concrete piles.

These foundation techniques differ in the excavation process used,

the method of constructing the supporting excavation, and the method of placing the concrete.

The choice of foundation technology depends on soil conditions,

availability of equipment and skilled labour, site-related technical specifications, and total cost.

Construction techniques for cast-in-situ reinforced concrete pile

Rotary drilling with Kelly, casing backed well

This method uses rotary drilling to drill a well, with the casing supporting its sides.

The casing is a steel tube with a diameter slightly larger than the diameter of the pile,

It is driven into the ground using a rotating motor before the drilling process begins.

The envelope oscillator can be used for larger diameters and greater depths.

This technology is suitable for all types of soils and narrow construction sites.

A notable advantage is that it does not produce vibrations while drilling.

The pile diameter varies from 60 cm to 180 cm.

The depth of the mound is 40 m, with the possibility of reaching greater depths.

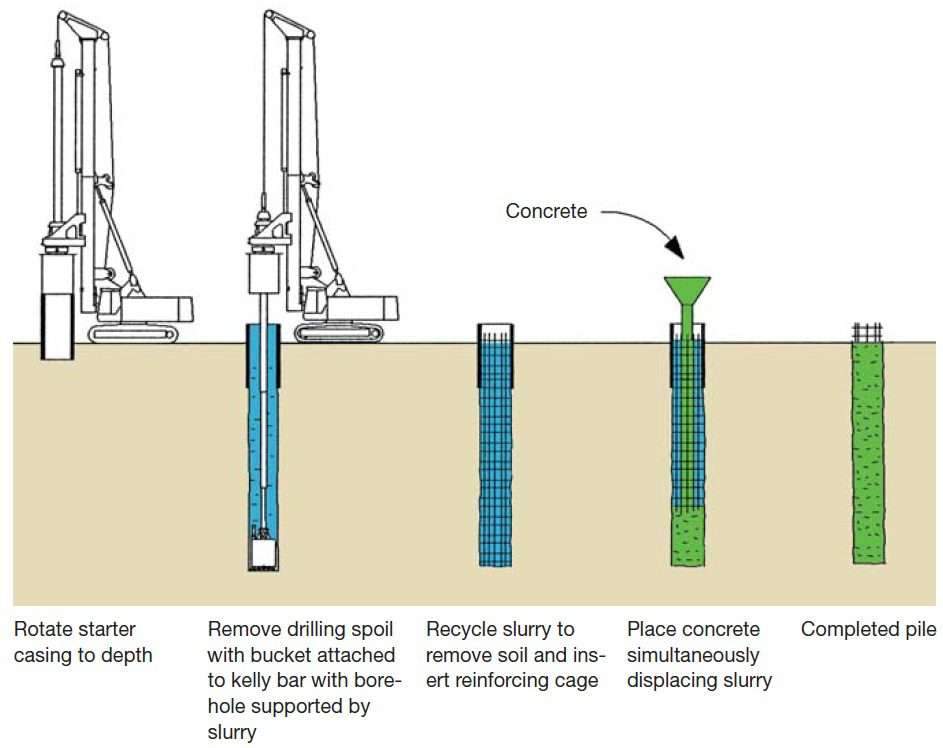

Rotary drilling with Kelly, hydrostatic pressure supported well

In this technique, rotary drilling is used to drill the well,

but bentonite solution or polymer slurry is used to support the well wall.

A short length casing is used at the start of work to guide the drill,

and a bucket extracts the pit slag.

This construction method is suitable for all soil types,

large pile diameters and depths, and vertical piles.

The excavation process, again, is vibration-free,

and the pile depth can be about 40 meters or deeper,

and the diameter varies from 40 cm to 240 cm.

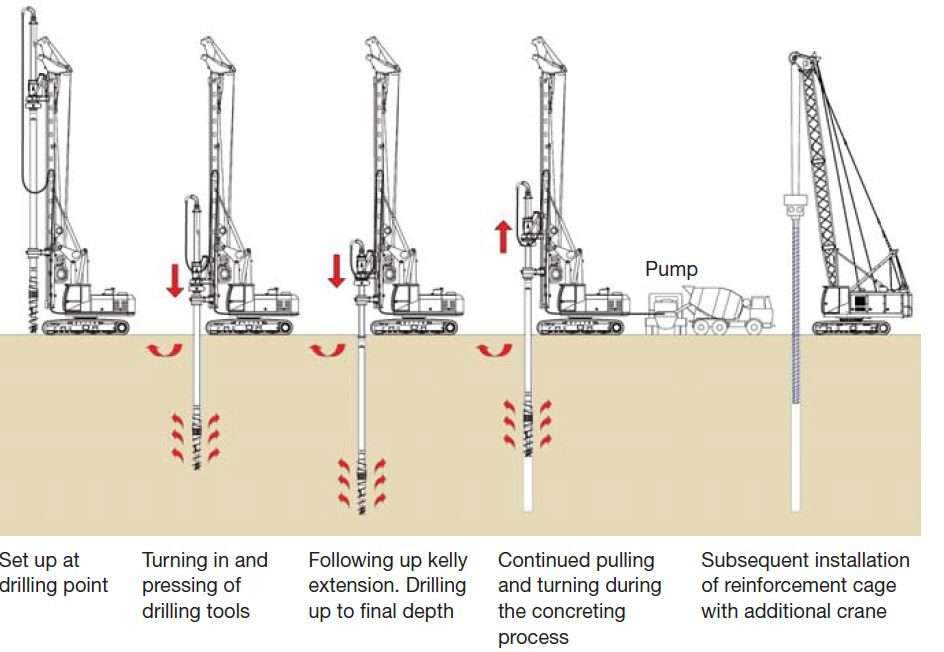

Rotary drilling using a double rotary head

Dual counter-rotation drives allow contractors to perform continuous flight drill bit drilling and casing installation simultaneously.

It is suitable for all soil types in narrow sites and can be installed on existing walls.

A construction machine does not generate vibration,

which is a desirable feature, especially in urban areas.

The depth of the mound is about 15 meters,

and the diameter varies from 63 cm to 88 cm.

In this technique, the pouring of concrete is performed while the auger is raised.

Therefore, the reinforcing cage is placed after the completion of the concrete casting.

This is why vibration or driving force is needed for reinforcement cage placement.

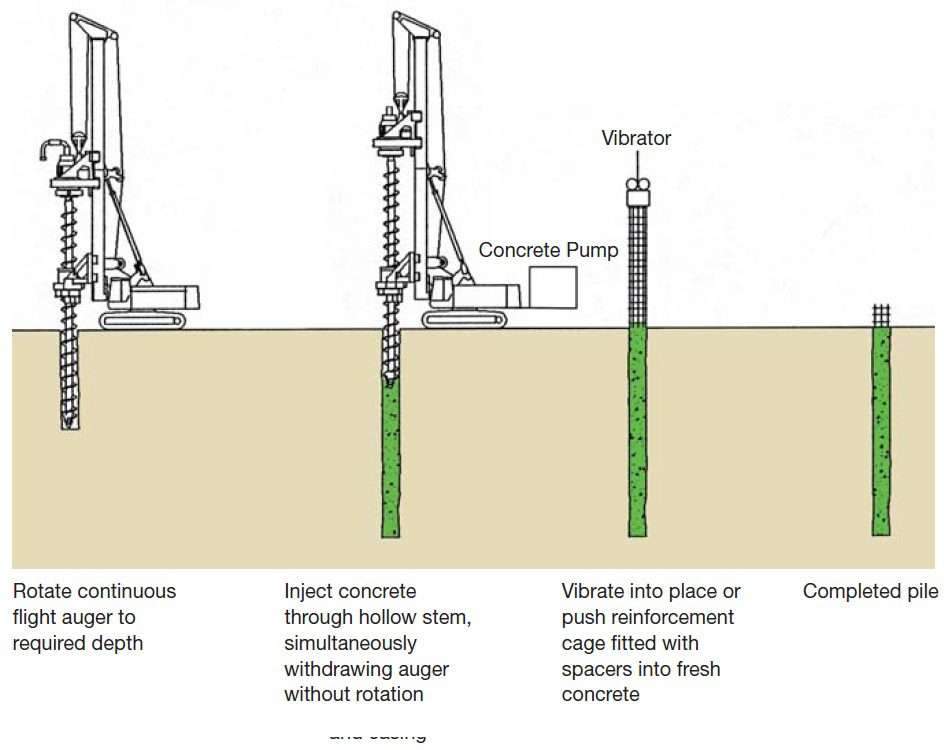

Cast auger pile on site

The continuous auger is used to drill the well,

lift the excavated soil, and pour the concrete while moving the auger.

As a result, the well does not require casing or hydrostatic pressure to prevent damage to the well wall.

The in-situ auger pile is suitable for all kinds of soils and construction sites with limited space.

It is vibration free, and can easily reach a depth of approximately 18 metres.

The diameter of the cast-in-situ abutment ranges from 40 cm to 100 cm.

Build pile offset

Displacement pile is a unique pile construction method,

which is suitable for contaminated soil to prevent excavation waste disposal.

It is also suitable for soft soil and narrow construction sites.

The special features of offset piles are high bearing capacity due to skin soil compaction,

avoidance of excavation spoilage, high performance,

and reduced concrete utilization compared to auger piles poured in situ.

The excavation diameter is 42 cm, 51 cm, and 61 cm, and the pile depth is about 34 m.

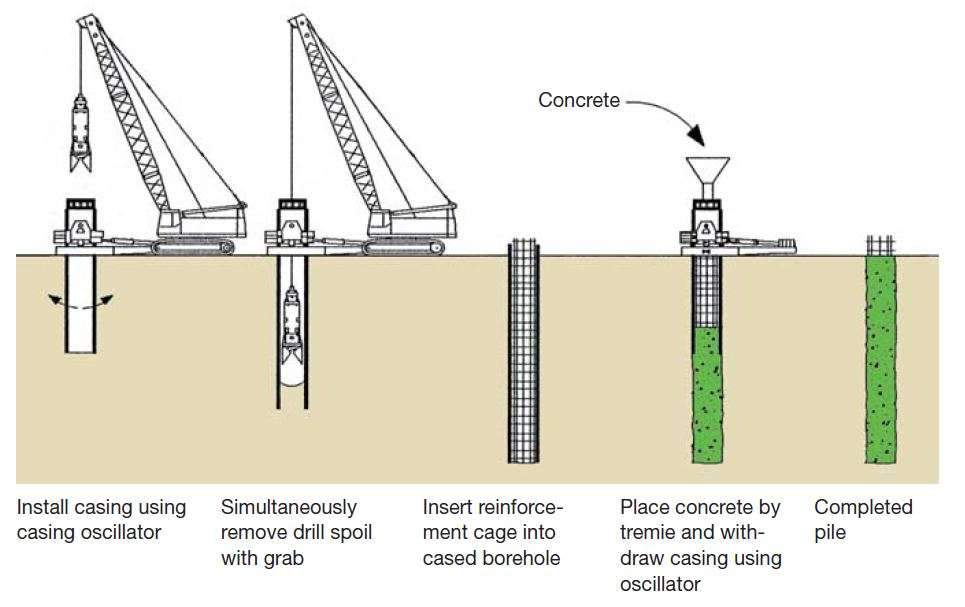

Grab construction, casing supported borehole

The crawler crane and the casing oscillator are used in the construction of the grab pile.

Grab construction is suitable for certain types of soils, such as sand and gravel,

with higher demands on casing technology.

It is also suitable for locations where it is economically feasible to use a chisel to break bedrock and rock.

Al-Mask building needs a minimum distance from the existing structures because it does not affect its surroundings.

The diameter of the mound varies from 62 cm to 200 cm,

and its depth is about 50 meters.

For more architectural news

العربية

العربية