Glass Fiber Reinforced Concrete (GRC) The Building Material of the Future

In today’s fast evolving world of architecture and construction, engineers and designers are developing new materials to meet the growing demands for modern design, durability, and sustainability.Glass Fiber Reinforced Concrete (GRC) is gaining popularity among engineers and architects due to its strength, adaptability, and ability to support complex designs.

What Exactly Is GRC?

Contrary to what many might assume, GRC is not simply an upgraded version of traditional concrete. Engineers designed it as a composite material to deliver high performance with unique properties. It combines cement, silica sand, alkali-resistant glass fibers, and various additives to enhance its final characteristics.

Unlike conventional reinforced concrete, which relies on steel reinforcement, GRC uses glass fibers mixed directly into the material to provide tensile strength and resist cracking. As a result, GRC offers impressive strength while being significantly lighter, making it easier to handle and install.

Key Components of GRC:

- Cement: Acts as the binding agent and provides compressive strength.

- Silica Sand: Adds volume and helps reduce shrinkage during curing.

- Glass Fibers: Deliver flexibility and reinforce the structure against cracks.

- Additives: Such as polymers or pigments, to improve texture, color, and overall performance.

Why Choose GRC?

If you’re looking for a material that balances practicality with aesthetics, GRC could be your answer . Here are some of its most compelling advantages:

- Lightweight: Surprisingly strong for its weight, making transportation and installation easier.

- Highly Resistant: Does not rust, withstands weather conditions well, and resists moisture and corrosion.

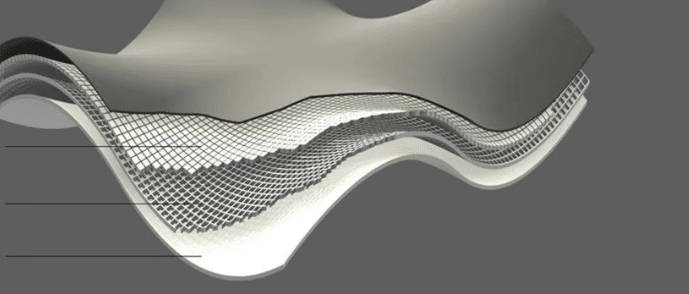

- Versatile & Moldable: Perfect for creating intricate shapes and detailed designs.

- Cost-effective in the long run: Lower maintenance costs and quick installation.

- Environmentally Friendly: Made from natural materials and manufactured using processes that reduce carbon footprint.

Where Is GRC Used?

GRC’s adaptability has allowed it to find applications across a wide range of fields. You’ll find it used in ways that would have been unimaginable with traditional materials:

In Architecture:

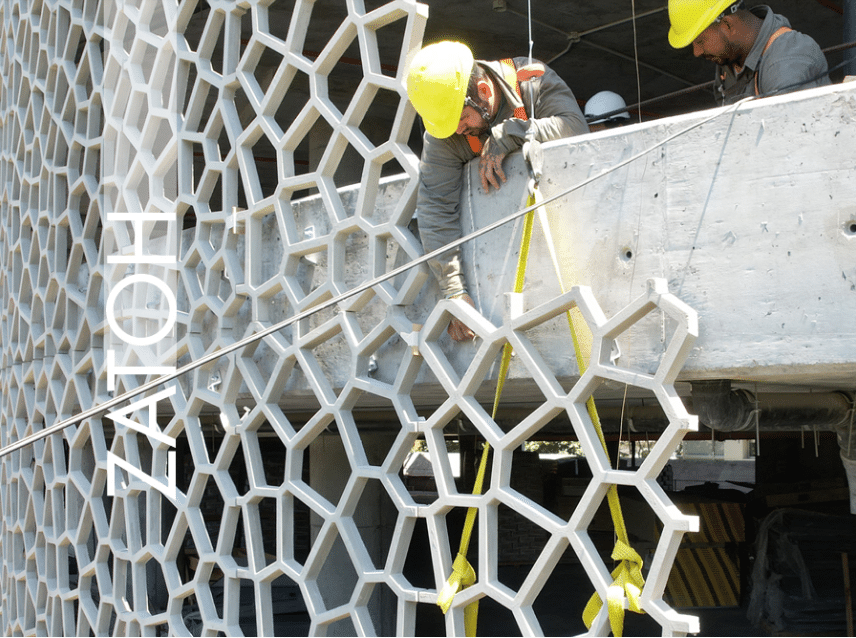

- Building Facades: Sleek, custom panels that double as insulation.

- Decorative Elements: Cornices, moldings, and ornamental features that add artistic flair.

In Construction:

- Ceilings & Lightweight Flooring Systems: Offering structural strength without added weight.

- Interior Partitions & Decorative Screens: Flexible and aesthetic space dividers.

In Art & Design:

- Sculptures & Monuments: Highly detailed art pieces made with precision.

- Outdoor Gardens & Water Features: Durable planters, fountains, and animal drinking basins.

In Infrastructure:

- Bridge Barriers & Road Safety Elements: Lightweight yet strong enough for heavy-duty use.

- Prefabricated Units: Built off-site and installed ready-made, saving time on construction schedules.

How Is GRC Manufactured?

Producing GRC requires careful attention to detail throughout the process. There are two main methods commonly used:

1. Spray-Up Method:

- A liquid cementitious slurry is prepared first.

- It is then sprayed onto a mold using air pressure.

- Glass fibers are simultaneously chopped and added during spraying to build up layers.

- Once hardened, the finished product is removed from the mold and prepared for installation.

2. Premix Method (Hand Casting):

- Manufacturers combine cement, sand, water, and additives in a precise mixture.

- Workers incorporate chopped glass fibers into the mixture to enhance strength and flexibility.

- Technicians pour the GRC mix into molds and use vibration to eliminate air pockets.

- The GRC piece remains under plastic sheeting for a full day to ensure proper curing and avoid distortion.

Both techniques allow for creative freedom and precision, making GRC a favorite among architects and designers alike.

GRC vs. Traditional Concrete: A Quick Comparison

| Feature | Traditional Concrete | GRC |

|---|---|---|

| Weight | Heavy | Light |

| Strength | High compressive strength | Higher tensile strength |

| Flexibility | Limited | Highly moldable |

| Maintenance | Requires regular upkeep | Resistant to wear and tear |

| Installation | Needs heavy equipment | Easy to transport and mount |

What’s Next for GRC?

As innovation continues, researchers and manufacturers are exploring ways to further enhance GRC’s capabilities. Some promising developments include:

- Improving thermal and acoustic insulation properties.

- Integrating smart materials into the mix.

- Reducing energy consumption during production.

- Recycling industrial byproducts for sustainable manufacturing.

All of these advancements aim to make GRC not only a high-performance material but also a truly eco-friendly one.

Final Thoughts

Glass Fiber Reinforced Concrete (GRC) is more than just another construction material it represents a paradigm shift in how we design and build our cities . Combining strength with beauty , and innovation with sustainability , GRC is paving the way for smarter, more efficient, and more expressive architecture.

At ArchUp , we continue to follow these transformative trends and showcase groundbreaking projects that redefine how we shape our built environment.

Whether you’re an engineer, architect, designer, or simply someone passionate about the future of construction, GRC proves itself, time and again, to be a material of the future today.