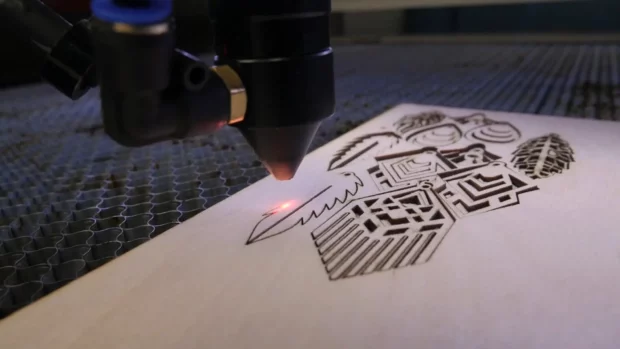

The laser engraving process requires a laser to achieve sublimation, which turns it from solid directly into gas. This creates deep marks on the surface of the material.

Laser engraving machines are some of the most useful tools when you want to customize, personalize, and add permanent marking to many materials, including metals.

In this beginner’s guide, we’ll discuss what laser engraving is, how it works, different types of it, and more.

What Is Laser Engraving?

The term engraving refers to the process of cutting or carving a design onto a material’s surface. Laser engraving sublimates use a focused beam of light to do this process.

This part of laser engraving is a process of turning a solid into a gas so quickly that it doesn’t have time to turn into a liquid first.

It uses a high-energy-density laser beam to vaporize the surface material to perform permanent marking.

This process is usually used when precision and speed are needed in marking a surface. Certain metals and plastics are oftentimes the canvas where the engraving process happens.

You can see the results of laser engraving on things like a keychain, logo transfer onto a wooden board, or on decorative items, you want to display.

How Does a Laser Engraver Work?

A laser engraving machine is a lot quicker and more precise compared to other engraving machines that aren’t using a laser.

Using the Laser

A laser beam acts as a chisel by using high heat, performing incising marks or thin lines on the surface of the material, and removing layers.

Using laser engravers involves using a laser engraving machine to reach vaporization temperature to engrave permanent marks on the material.

The laser light and powerful laser beams instantly turn solid into gas when it hits the surface. This skips the liquid phase because of the high temperature.

This process is really dependent on having enough energy to reach vaporization temperature. Without this, you’d only achieve the laser marking temperatures.

Precision and Speed

The surface instantly absorbs the heat. As long as enough energy is injected to reach vaporization temperature, the machine will work properly.

This instant engraving allows for a quick marking speed. If you’ve seen videos of laser engraving, you’ll know that the laser hits localized areas and glides over them quickly.

Similar to inkjet marking in printers, laser engraving uses precise calculations coming from the computer to guide the machine.

This reduces the chances of random errors happening in the process. Although it still sometimes happens, it’s rare compared to hand-engraved processes.

How Long Is the Laser Engraving Process?

The whole process takes between three to five minutes, depending on the laser engraving system, the size and complexity of the design being made, the engraving depth, and the material.

This makes it ideal for high contrast, high precision processes like in rapid manufacturing. Engraving on things like metal signs needs high-quality contrasts and is quicker to finish.

On the other hand, more complicated engraving processes with different specified colors take longer but don’t require a high-contrast background to be visible

FUN FACT

The Printing Press was a bunch of small engravings that had ink added onto them and pressed onto the paper. This greatly sped up the production of books.

Is Laser Beam Engraving Permanent?

Having something laser engraved, whether coated metals or wood, means the material will have permanent markings. This is because the material is vaporized and changed forever.

This is perfect for use on things that you’d want to last just as long as the material itself, like jewelry, diamonds, and other unique items that need permanent marks.

On high-contrast materials like uncolored stainless steel, it’s even more visible and doesn’t get rubbed off easily.

The only way to remove laser engraving is to destroy the surface material, like cutting a sheet of metal to the depth of the engraving depth so that it looks clean and flush again.

The Pros and Cons of Laser Engraving Technology

Next, we’ll discuss the advantages and disadvantages of using a laser engraving machine in laser marking your materials.

Pros

- Highly precise, making high-quality marks like to engrave barcodes

- Works with a wide range of materials

- Easily repeatable, ideal for high-volume manufacturing

- Can be done with a wide range of materials

- Marks are permanent and stay that way forever

Cons

- Complicated and needs trained personnel

- Expensive to buy, operate, and maintain

- Emits dangerous fumes when vaporizing

Differences Between Laser Engraving, Marking, Cutting, and Etching

You may have heard different but related terms like laser marking, laser cutting, and laser etching. These are not the same, but all use laser technology.

In this section, we’ll discuss the differences between each one and give a few examples of how they’re used in real life.

Laser Engraving

When you laser engrave a material, it requires you to vaporize the material. This means reaching a high vaporization temperature to turn solid straight into gas.

The extreme temperatures required are used to create deep crevices on the material’s surface that cannot fade or disappear, unlike some other laser-based processes.

Examples of laser-engraved objects include custom engraving on a pen or a watch. Jewelry is often laser engraved as well.

Laser Marking

Source: Kernlasers

Laser marking only creates a slight alteration to the surface of the material instead of creating deep marks like when getting something laser engraved.

Usually, this alteration is done by changing the color of the material. A low-power laser is used to dramatically increase the temperature of the surface.

A few examples of this are like using laser marking to mark logos onto wooden boards or a QR code onto metal signage.

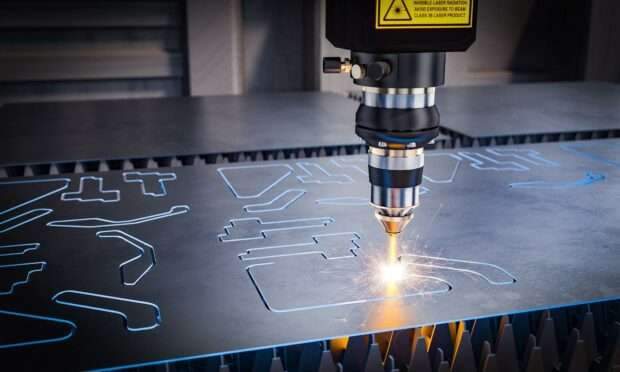

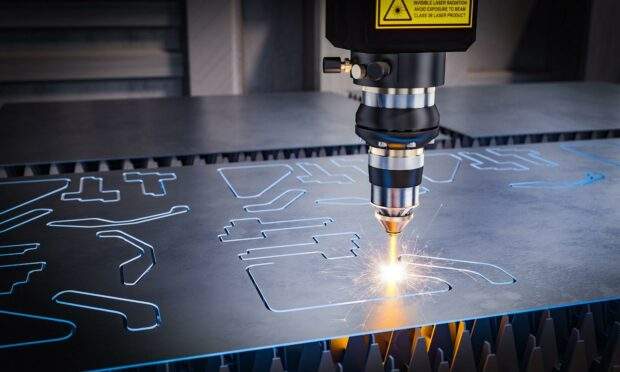

Laser Cutting

Laser cutting is similar to using laser engravers in the sense that it just adds more high peak power to the laser.

While a laser engraving machine can only create deep crevices, a laser cutter increases the power so that it can cut straight through the material, splitting it into two pieces.

A few examples of this are when cutting metal plates and blocks for use in car parts or cutting tiny patterns through the wood.

Laser Etching

Laser etching has to be the closest to laser engraving because they have closely similar processes. While laser engraving doesn’t need a special fiber laser, laser etching does.

Laser etching melts a smaller part of the material surface compared to laser engraving and needs a fiber laser to do this.

The fiber laser engraving process removes less from the material surface than using non-fiber lasers. The temperature on these fiber lasers is also higher.

Laser etching has the same real-world use cases as laser engraving. However, if the material is thinner, then etching is the preferred solution.

What Are the Different Types of Laser Engraving Machines?

There are two major types of laser engraving machines that the industry uses, UV and fiber. We’ll discuss the differences between each one below.

UV Laser Markers

UV laser marking or engraving uses lower energy. It has a wavelength of around 355NM, meaning it’s considered a “cold laser.”

The lower power means it’s ideal for engraving organic materials and softer materials like glass or plastic without burning them.

Fiber Lasers

A fiber laser works differently because it’s a high-powered laser. Therefore, it’s better suited for metal engraving and for use on harder plastics.

This is because it operates on a much higher wavelength, reaching up to 1070NM. That’s nearly triple the UV laser.

Whichever laser engraving machine you choose, you should pick one that fits the materials you’ll be using more.

The Different Materials Used for Laser Engraving

One of the advantages we listed inherent in how laser engraving machines work is that they can use various materials. However, there are also some materials you can’t use.

We’ll discuss both in this section.

Materials You Can Use for Laser Engraving Work

Here are the materials you can laser engrave. Note that you may have to use different types of lasers to cut each material because of differing depths and melting/vaporizing points.

- Aluminum and stainless steel

- Most metals

- Brass and copper

- Acrylic and polycarbonates

- Ceramics, glass, wood, and thicker fabrics

Materials You Can’t Use for Laser Engraving Work

These are the materials you shouldn’t use when laser engraving. It will either damage the material or completely cut through it instead of leaving marks.

- Paper (although it can be used with laser markers)

- Cardboard

- Thinner fabrics

Things You Can Make With a Laser Engraving Machine

Another advantage to how laser engraving works is that you can use your creative juices to the max. We’ll discuss what they are here:

Decorative Items

Vases, jewelry boxes, and wall hangings are just a few things you can design with a laser machine. Just make sure to use the correct laser power for the material used.

Customized Objects

If you use everyday items and want them to have a personalized touch, laser engraving is a process that can help you.

Examples of items you can engrave are pens, bottles, glass, belts, or tumblers. With care, you can even engrave your laptop or smartphone.

Identification Marks

Similar to customized objects, laser engraving is usually done for identification purposes. Let’s say you have diamonds or jewelry. You can engrave your name on them.

Another identification mark we see used a lot is QR codes engraved into a wooden sign for customers outside a restaurant to scan and access the online menu.

DIY Projects

DIY projects using steel, wood, or other materials are easy when you use laser engraving. You can alter how a surface looks by using it.

On materials that are thinner, you can still use a lower-powered laser light to either have it marked or engraved.

Frequently Asked Questions (FAQs)

After learning about laser engraving, you might have a few questions related to it. We’ve answered the most commonly asked questions below.

Do You Need a Computer for a Laser Engraver?

Yes, you need to have a computer to perform laser engraving. To achieve pinpoint accuracy and quick marking speed, the laser follows precise computer-generated algorithms.

You will need both the computer hardware and the necessary computer software to be able to control the laser engraver.

You can’t control these yourself manually because human reaction times and human error make controlling a laser engraving machine nearly impossible.

Additionally, a computer allows you to make on-the-fly adjustments directly from the design software to the engraving software, adding to the convenience.

Can I Earn from Laser Engraving?

You can earn from laser engraving if you have the proper equipment and know how to operate it.

You’ll also need to know the correct laser type, get a fume extraction system, and know whether high heat or low heat is required, among other things.

You will have to do quite a few jobs before you get your full return on investment, but with the number of people into laser engraving today, you’ll earn it back in no time.

Is Laser Engraving Hard to Do?

If you’re a complete beginner, then it will be extremely difficult. You need to study how the laser marking process or laser engraving process works.

Then, you’d need to buy the equipment and materials that laser engraving needs and get used to operating them.

Laser engraving will get easier when you continuously operate the equipment needed, like computer programs and the actual laser engraving machine.

Do Laser Engravers Use a Lot of Electricity?

Machines that do laser engraving use up electricity equivalent to two personal computers. Engravers have an average working time of two hours but are not always at full power.

It will use 80 watts of power at maximum power only half of the time, while it will use 40 watts or half power the other half of the time.

How Deep Can a Laser Engraver Cut?

Some higher-powered laser engraving tools can engrave up to 20mm in depth. However, most lasers out there engrave on a depth range of about 0.5-12mm deep.

If you’re looking to cut instead of engraving, you should look for dedicated laser cutters that have a higher power that engraving tools can’t reach.

How Much Does a Laser Engraving Machine Cost?

The lowest-end models can be as low as $100 but can stretch all the way upwards of $10,000 for the more industrial-focused models.

The general rule is the higher the price, the higher the laser power that it’s capable of outputting. Therefore, if you want to engrave deeper, you may have to spend more.

This only includes the cost of the machine itself. You’ll have to factor in the computer it will connect to, the software, and the materials you’ll use (including the electricity).

Conclusion

Laser engraving is one of the processes that are appropriate when you want something precise, that can save you a lot of time, and that’s not easily erased.

Marking jewelry and pens, putting logos on wooden boards, or engraving metals are just some of the many uses that laser engraving allows users to do.

As long as you understand which materials can be engraved on and which laser to use, feel free to use any.