Karuun: discovering the beauty of nature thanks to material design

Engineered rattan showcases its remarkable versatility as a material that seamlessly blends nature and technology, providing inventive and eco-friendly solutions across various industrial sectors

Karuun is an innovative and sustainable material developed from the transformation of rattan. A climbing plant that grows in the tropical forests of Indonesia. The plant of rattan has been exploited for centuries for the production of furniture and everyday objects. But thanks to a process patented by the German company Out for Space, it has acquired new properties and potential.

Description & History

The transformation process starts with injecting a UV-resistant pigment into the capillaries found on the section of cut and squared rattan sticks, which are then glued together to form blocks, panels or structures of different sizes and colors. This process allows modification of the natural structure of the rattan, making it a more stable, resistant and flexible material. Furthermore, such obtained material is permeable to light and air, has excellent workability and showcases original aesthetics.

Karuun was originally launched in 2018 under the registered brand named karuun®, which means “treasure” in the local language. Since its launch, it attracted interest from various industrial sectors, which have adopted it for the production of ecological and high quality products.

Applications and Use Cases

Among these sectors, the automotive industry stands particularly out, as this solution was chosen by the Chinese electric vehicle manufacturer Nio to coat the interior of its ET7 Sedan. Indeed, Karuun offers a valid alternative to plastic shells and covers, with the advantage of being a natural, renewable and biodegradable material.

But this way of integrating rattan in modern design is not limited to the automotive sector. The material has also found applications in sustainable architecture, product and furniture design, sporting goods and electronic devices. Thanks to its properties, it can satisfy both functional and aesthetic needs in these areas.

Formats and variants

Thanks to its versatility and its range of technical and chromatic shades. Karuun® is manufactured in four variants: Block, Stripe, 3D and Shine.

Karuun® block is composed of rattan sticks glued together to form solid blocks, which can be cut and shaped as desired, and is the raw material to work with for creating three-dimensional objects with a smooth and uniform surface.

Karuun® stripe consists of thin strips of rattan glued onto a flexible support, which can be bent and shaped as needed, thus perfect for covering rounded or curved surfaces or creating postforming elements.

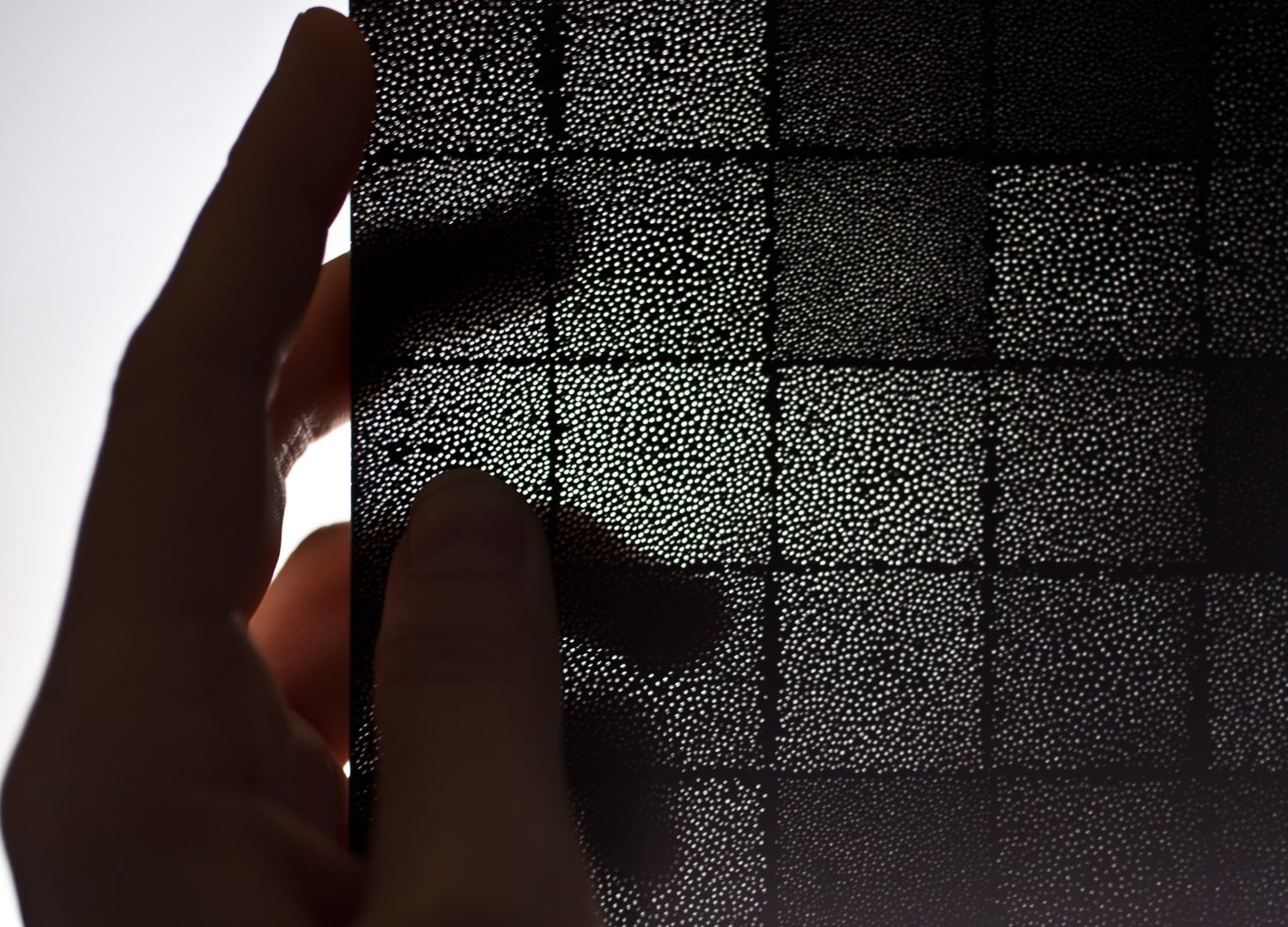

Karuun® 3D consists of aligned longitudinal rattan fibers and capillaries, together with a robust, waterproof, 3D cellulose nonwoven fabric that come together to create spherical objects of different sizes, from those of a button to those of large shaped components. This variant is suitable for producing three-dimensional objects with an irregular and dynamic surface.

Finally, Karuun® shine is obtained from rattan sticks woven together to form a light and transparent net, which can be illuminated from inside or outside. We suggest this variant for creating luminous objects or decors with a soft, warm surface to the touch.

Pros, when and why

Beyond its technical and aesthetic characteristics, this material also has a strong social and environmental impact. Rattan plants grow very quickly and do not require the felling of the trees they climb on. Their cultivation therefore contributes to the conservation of tropical forests and biodiversity, since for production the ecosystem must be preserved.

Moreover, considering the transformation process of rattan becoming such a structural material, each phase is energy-efficient and produces no waste. The production also supports the economic development of local communities involved in the collection and processing of rattan.

Takeaway

In conclusion, engineered rattan proves to be a really versatile material that combines nature and technology. Offering innovative and sustainable solutions for different industrial sectors. It represents a real challenge to the dominance of plastics for certain uses, demonstrating that it is possible to create high quality products with respect for the environment and people.

Read more on Archup: