Gypsum board is a type of covering used for interior walls. Gypsum board is mainly composed of gypsum core, with a paper surface covering the face, back and long edges.

The plaster core, consisting of hydrated calcium sulfate, is sandwiched between two layers of heavy paper, and a slurry of calcined gypsum (and other additives) is introduced.

The water is in an envelope, from the paper of the wallpaper, then solidifies, and the excess water is removed in a high-temperature dryer by evaporation through the pores of the paper.

Common names: drywall, wallboard, gypsum board, rock board

Gypsum ceiling panels are available in different options – Pre-printed / Unpainted / PVC Film Laminated / Perforated panels.

Features and advantages:

Fire resistance: Its core contains chemically compound water, under high temperature, it is slowly released in the form of steam, effectively blocking heat transfer.

Sound Isolation: Effectively helps control sound transmission.

Durability: Excellent dimensional stability, easy to decorate and finish surfaces.

Economy: Less expensive, readily available, and easy to apply

Versatility: Adaptability to different types of decoration, lightweight, flexible and versatile in nature.

aesthetics

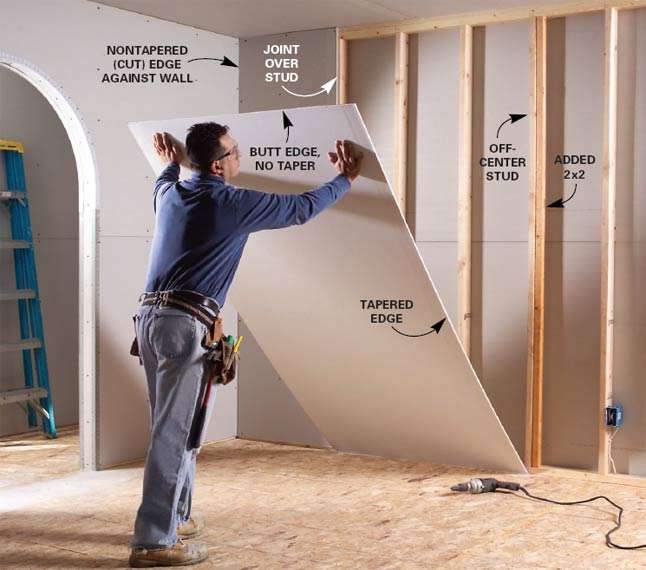

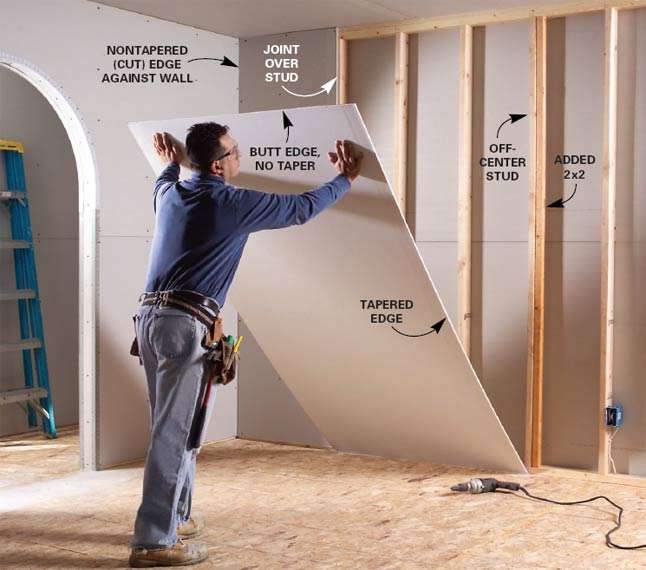

Edge types:

round

Square

Pointed edges

beveled edge

Tongue and groove

Sizes:

Common thicknesses used – 1/4, 3/8, 3/4, 1/2, 5/8

Standard gypsum board is 4 feet wide and 81012 or 14 feet long, generally available in 600mm x 600mm tiles.

Width is compatible with standard spaced stud frame.

Types of gypsum board

Different types and names are available as they vary by manufacturer, location, use, etc. The most common are:

Plain Gypsum Boards / Plain Boards:

Covered with gray face paper on one side and brown paper on the back side.

Thicknesses range from 3/8″ to 1

Perfect where a smooth finish is required.

Moisture resistant panels:

Covered with green/brown face back paper.

It contains an aerated gypsum core with water-repellent additives.

Suitable for areas exposed to moisture.

fire resistant panels:

It is covered with a pink and brown face paper on the reverse side.

It consists of fiberglass and other fire-resistant additives.

Suitable for areas requiring fire protection.

Fire and moisture resistant panels:

It is covered with pink and green face paper on the back side.

It consists of fiberglass and other fire-resistant additives.

Ideal for areas where fire protection is required and also for areas that must be protected from moisture.

Basic gypsum board

Available as a 1″ thick, rigid hardboard or as a factory-laminated board of two 1/2″ boards.

It is used in column walls and gypsum laminate partitions, with additional layers of gypsum applied over the cardboard to complete the wall installation.

Gypsum packaging

It is used as a protective and fire-retardant membrane under exterior wall surfacing materials, such as wood siding, masonry veneer, stucco, and shingles.

Provides protection against the passage of water and wind.

Gypsum board application

The panels can be applied to any base – wood, metal or furring frames, and can be applied to concrete and masonry surfaces either directly or to wood or metal furring strips.

Single layer application

A single layer of gypsum used in residential and light commercial construction.

Multi-layered application

Double systems contain two or more gypsum boards and increase sound insulation and fire resistance performance.

Introduction to building materials in interior design