Architect: MJMA

Location: Mississauga, Ontario, Canada

Completion Date: September 2021

In Mississauga, Ontario, a community center designed by MJMA combines local influences with a mass-timber structure. Located on a 50-acre site that was once used for agriculture, the Churchill Meadows Community Centre and Sports Park includes gyms, locker rooms, multipurpose spaces, and a pool within a 75,000-square-foot building. Most smaller programs are located on the ground floor, an organization which makes space for the larger pool and gym areas to have double-height ceilings.

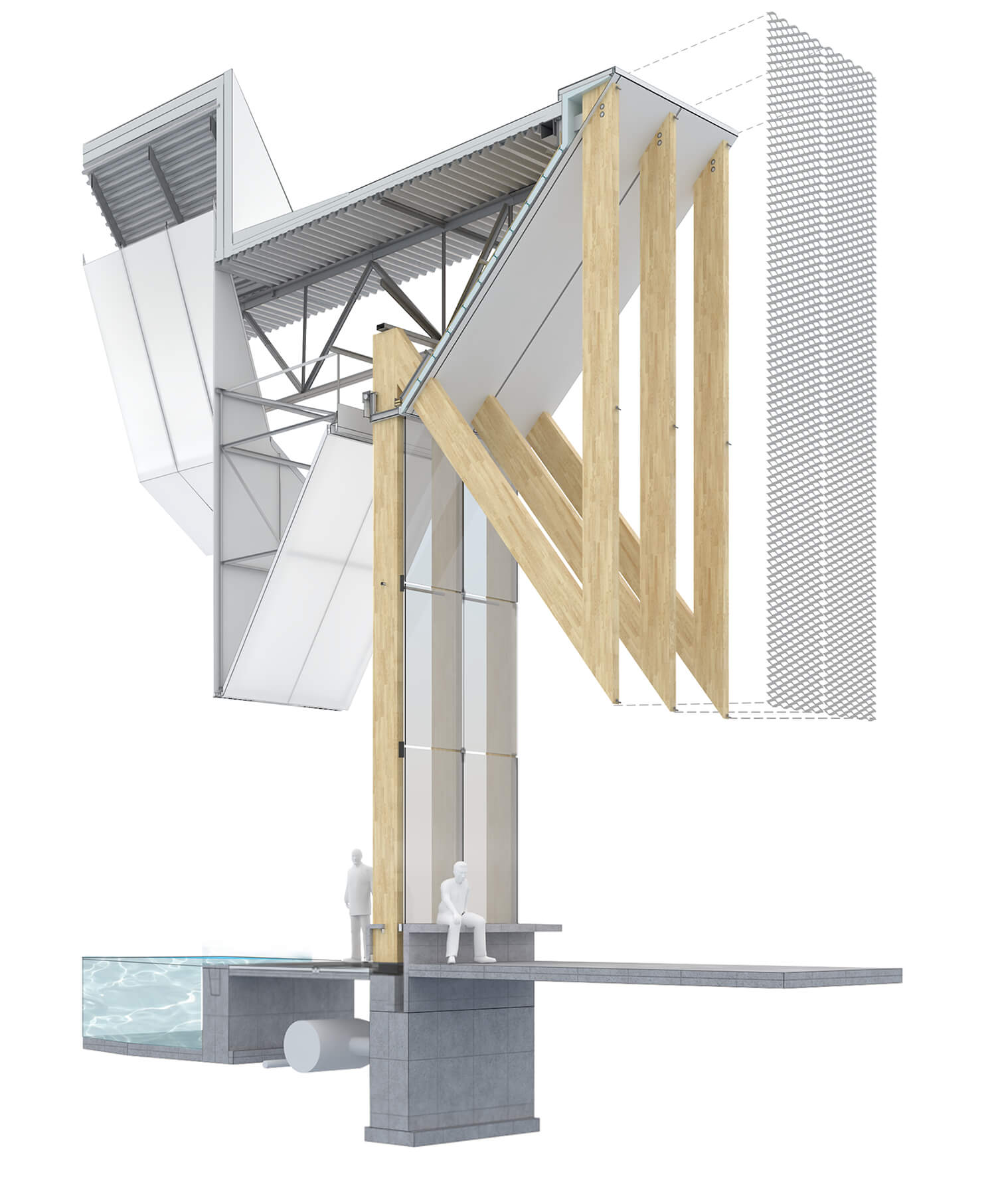

While the building’s plan is straightforwardly rectangular, its section is shaped by angled peaks in the roof that introduce daylight. An aluminum mesh screen clads the west- and south-facing facades and reveals the black spruce glulam members that structurally support the canopy.

As MJMA principal Chris Burbidge and senior associate Tyler Walker told AN, “the introduction of mass timber served multiple aims.” Inspiration came from the park itself, with the design team seeking to “reinforce the community connection to nature and the park beyond.” This was envisioned through the glulam columns, which Burbidge and Walker see as “mediating the linking of inside-to-outside along the full-length park side of the building.” This leaves views of the park open through the columns in the gyms, lobby, and pool.

The choice of timber also has environmental benefits in comparison to typical building materials like concrete and steel. In the pool space, timber “does not require extensive high-performance paint coatings for protection” against corrosive air, Burbidge and Walker explained, in addition to the embodied carbon benefits of the columns themselves.

On the facade, the columns were extended to an overhang, shading an adjacent playground and bicycle parking space. The aluminum screen installed around the facade was designed as a daylighting control mechanism, filtering sunlight “similar to a tree canopy,” Bubridge and Walker said. Operationally, this reduces mechanical loads from energy consumption with a passive daylighting strategy while maintaining the appearance of the building during the day. Burbridge and Walker described the shifting impression of the building at dusk as a move in which “the building begins to invert itself… the mesh dissolves, and the timber is fully revealed.”

The design team considered stainless steel chain link mesh, perforated aluminum sheets, and numerous metal slat systems for the screen, but installed aluminum mesh “for its consistency of appearance, economy of material, inherent rigidity, and longevity.” Through sun studies, the screen’s position on the western porch and relation to interior ceiling massing was analyzed to reduce glare in the pool and gyms while not eliminating reflected light. Heat gain was further mitigated by reducing the window-wall ratio and extensive insulation and thermal spacers “through most thermal bridging connections.”

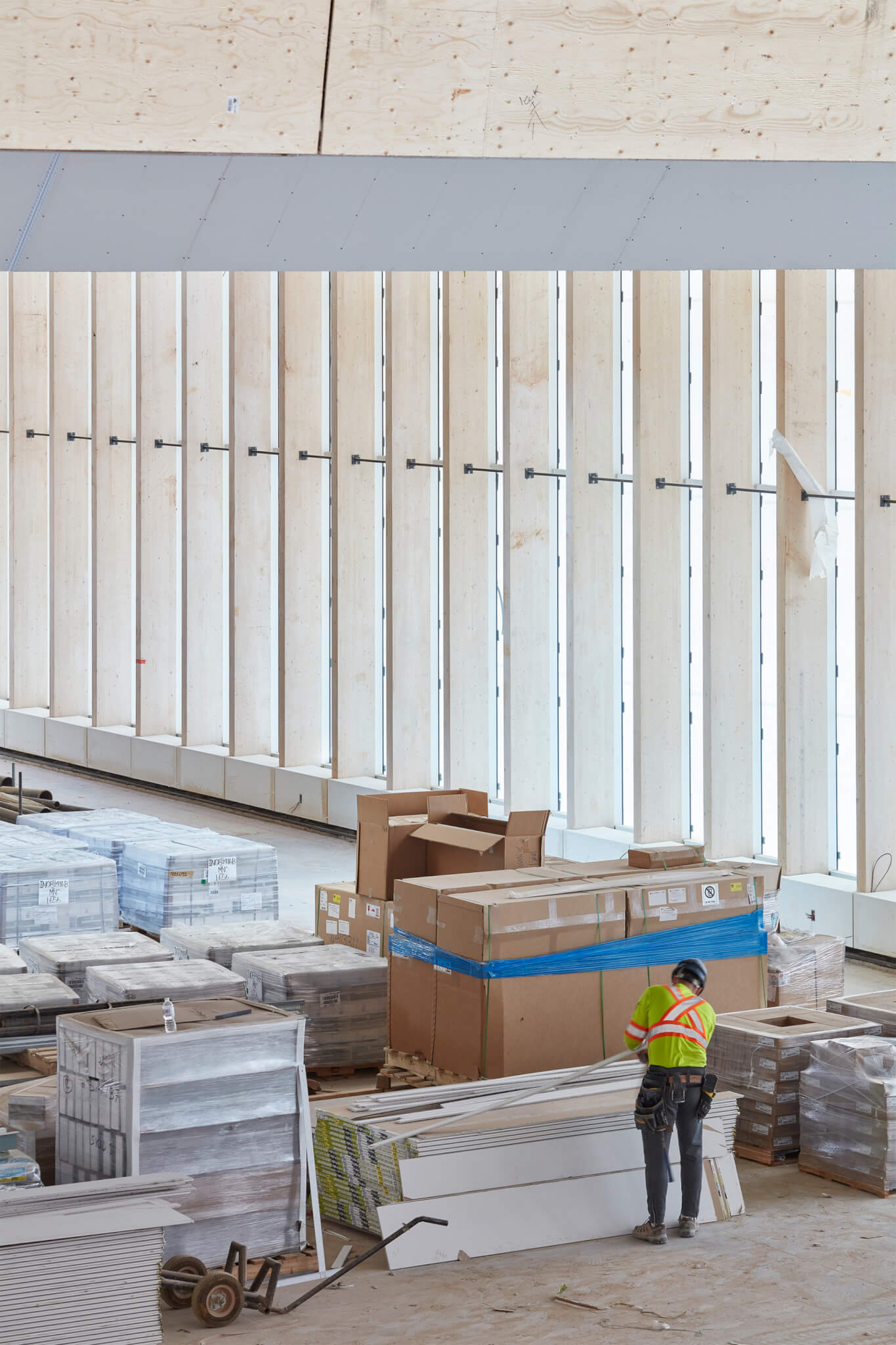

Careful attention was given to the design of the steel bracing members, leaving almost none visible, maintaining the building’s visual verticality. The glulam beams were “designed to work in groups of three to resist bending forces applied from the roof load,” Burbidge and Walker explained. The members were braced by a precast concrete bench at the bottom, and spaced with a “minimal” steel member at midspan. The lateral restraint systems were “buried” in the bar holding the locker rooms. These strategies combined to leave the wood structure exposed while hiding bracing members and transfer beams, with the glazing units connected to the columns via “a toggle system set between the lights.”

Burbidge and Walker noted that while Canada has abundant timber resources, they had trouble finding a timber supplier to take on the project given its complexity. Tolerances were carefully considered—especially in light of manufacturing constraints—and workers installed additional spacers and slotted connections to allow for natural variations within timber to maintain smooth connections with the mesh screen. MJMA worked closely with the contractor, Aquicon, to ensure that timber materials were shielded from moisture during the construction process. Additionally, structural engineers from Blackwell traveled to the timber production facility, operated by Nordic in Quebec, in order to perform quality control reviews.

The complete facade clearly maintains the visual cleanliness desired by the design team, while demonstrating a glulam column design that is not only for aesthetic purposes, but reflects both embodied and operational carbon concerns.

Project Specifications

- Architects: MJMA

- Location: Mississauga, Ontario, Canada

- Completion Date: September 2021

- Contractor: Aquicon

- Structural Engineer: Blackwell

- Glue-Laminated Timber and Cross-Laminated Timber: Nordic Structures

- Steel Structure Supplier and Installer: Gensteel

- Exterior Sun Control Device: Expanded Aluminum Mesh by Fratelli Mariani, distributed by SSI Architectural Systems

- Architectural Concrete Block: Richvale York Cambridge Series

- Metal Panels: Agway Metals AR Standing Seam Panels

- Glass Curtain Wall: Aerloc Industries

- Thermal Insulation: Cavityrock by Rockwool

- Air Vapor Barrier: Blueskin by Henry

- Wood Soffit: Geometrik Manufacturing

- Below-Grade Vapor Barrier: Perminator by W.R.Meadows

- Surface-Applied Crystalline Waterproofing (elevator pits and surge tanks): Vandex Super by The Euclid Chemical Company

- Cold Fluid-Applied Waterproofing (basement walls): E.Protect Wall System by Epro

- Bituminous Dampproofing (foundations): Epro