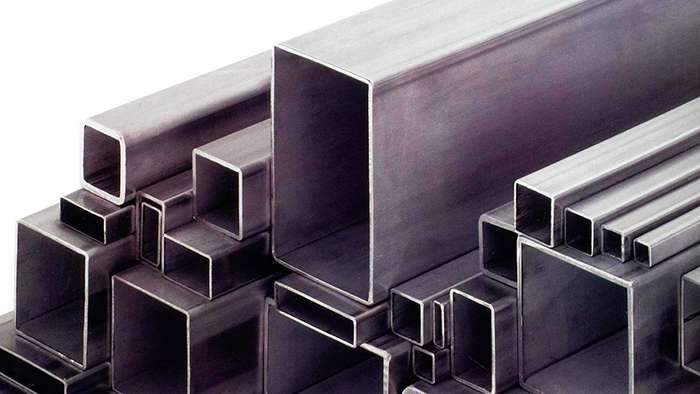

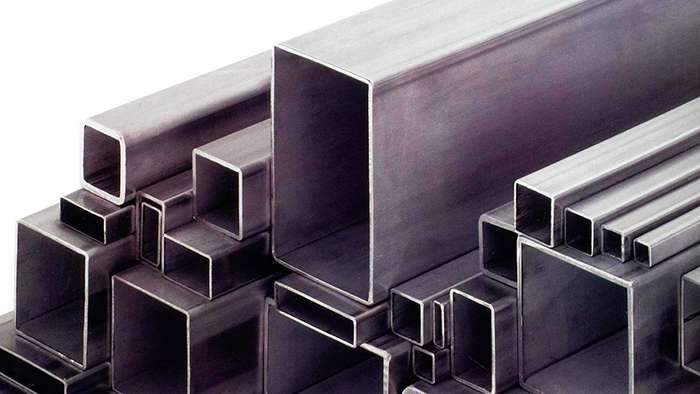

Square tubes and rectangular tubes

Square tubes and rectangular tubes,

The main differences between square tubes and rectangular tubes

Various uses of square tubes and rectangular tubes:

Square tubes and rectangular tubes,

Arab Architecture – Architectural Publishing Team

Arab Architecture is ArchUp’s dedicated editorial team focused on publishing high-quality content about contemporary architecture, urban design, and regional architectural developments. The team curates and reports on significant projects, design concepts, and influential movements shaping the architectural landscape in the Arab world and beyond.

Explore their latest architectural coverage here: ArchUp Architecture Section

Best Topic Editor 🏆 | Winner of the Strategic Vision Award - ArchUp

Home appliancesA solution to the passive hot water waste that occurs during the water warm-up period. In the U.S. alone, up to 360 billion gallons of hot water are passively wastedIn this interview, Adam Friedman, founder of Geology studio, a furniture and product design studio based in Claremont, CA, talks about the origins of his

Lamitex from Decoration WeekFrom traditional to bold glossy, Italian lamination brand Lamitex has launched four new mini collections as part of this year’s Decor Week. Lamitex has unveiled its latest collection of interior finishes to mark the start of the…

An architecture centre founded by British architect Terry Farrell has opened in Newcastle, England, with an exhibition exploring building materials of the future and “urban rooms” for local residents. The Farrell Centre is an exhibition gallery, research centre and community space that aims to provoke conversation about architecture and planning, both in the city and

Download our DWalking guide (pdf, mobile-friendly) with all the info for visiting. Formed of a collection of pillows in various tones positioned on a metal structure with flowing curves. The Plasma armchair merges the simplicity of a persistent visual character with the intricate technology of the structure, produced with computerized bending and welding techniques. © Plasma

Aria is a Half breed Air Purifier framework that distinguishes and disposes of almost 100% of all indoor air toxins. Plus it mixes inside the harmony of your home.A NASA-roused plan meets NASA-propelled innovation here. The Aria purifier utilizes something…

An additional building for a family home with a metal roof extension intended to surround an outside garden while “celebrating the Arizona sky” was created by US architecture studio Kendle Design Collaborative.The Flex Pavilion was created by local company Kendle…