CeraShingle: Exploring the Intersection of Craft and Digital Fabrication in Architectural Façades

The Relationship Between Craft and Technology: When a Robot Shapes Clay

There is a profound sense of satisfaction in watching the potter’s wheel spin, and seeing how the human hand convinces the wet clay to take on a vibrant form.

But what if this traditional craft were entrusted to a robot? Would the clay lose its soul, or would it transform into a new medium of material expression in the design world?

CeraShingle Project: Redefining Architectural Ceramics

This question sparked designers Yutao Chen and Yiwen Gu to launch their CeraShingle project, an architectural façade system exploring the intersection of handcrafted artistry and digital technologies.

The project aims to reimagine the role of ceramics in modern architecture, not merely as a decorative element, but as a living surface that interacts with light, shadow, and texture.

3D-Printed Clay: From Form to Experience

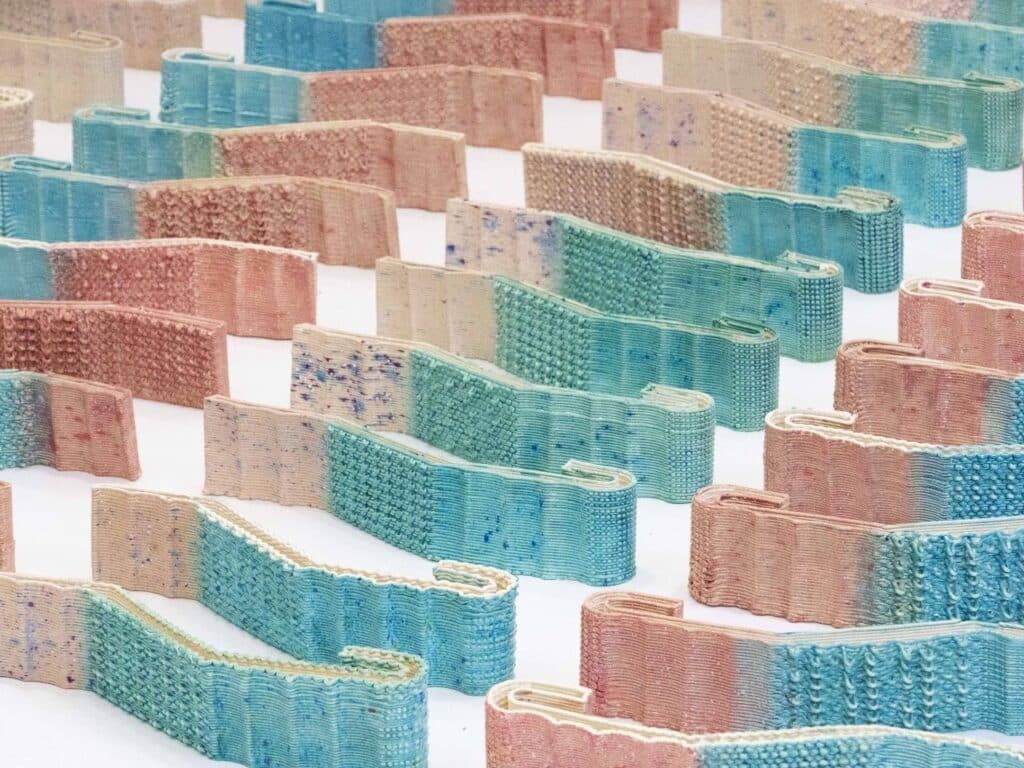

Instead of the flat, repetitive tiles typically seen on façades, CeraShingle units come as ceramic shingles printed using 3D technology.

These shingles feature intricate textures and subtle color gradations that flow across the surface like watercolor on paper, giving each piece a unique character.

Precision Technical Details

Each unit measures approximately 400 × 130 mm and weighs just over one kilogram. This relative lightness makes installation easy, while their durability ensures long-term resistance to environmental factors.

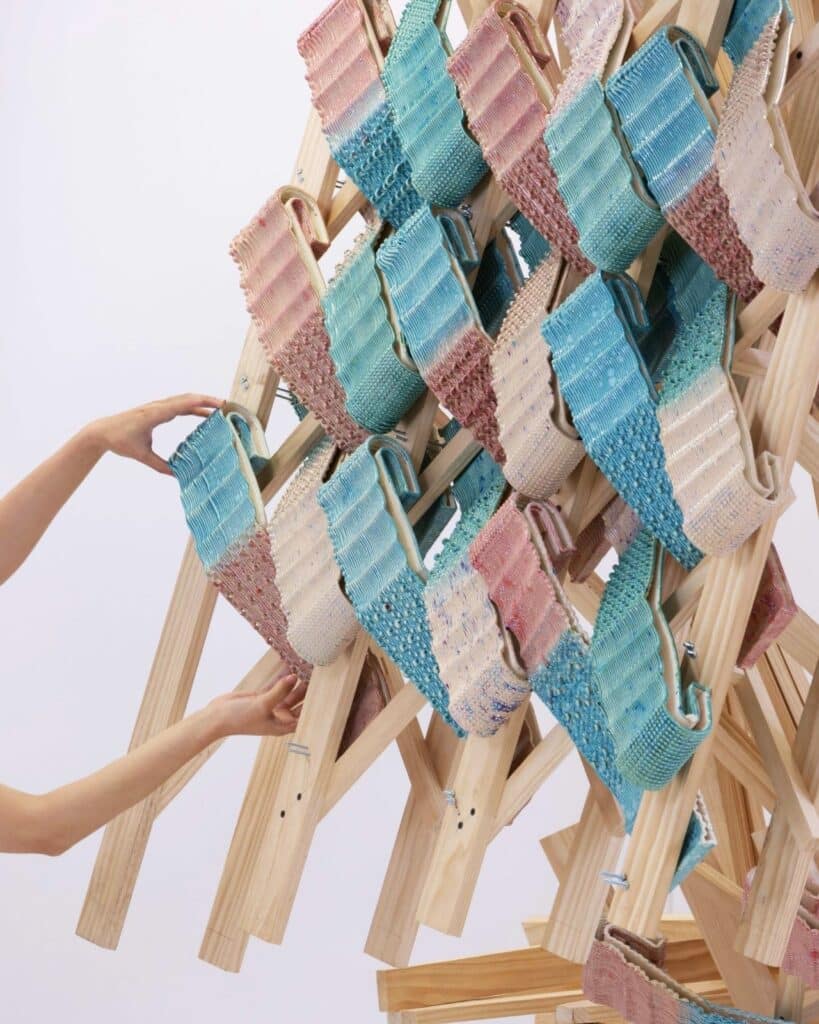

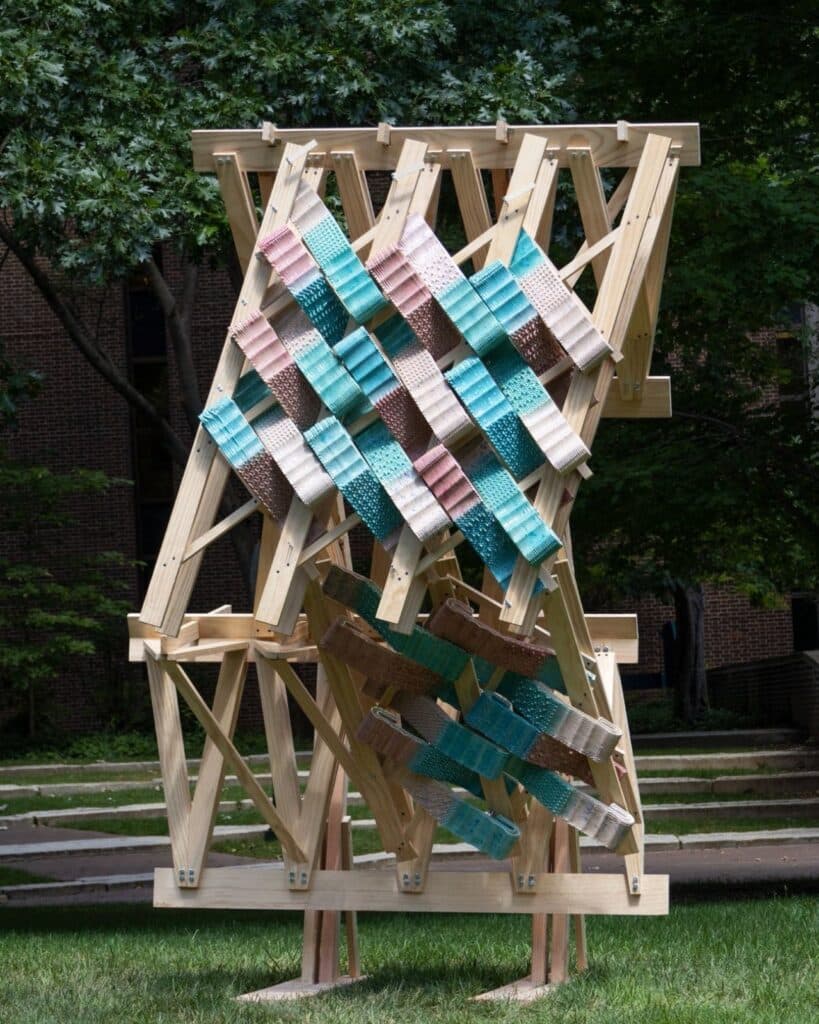

When installed in a carefully designed overlapping pattern, the façade forms a skin that seems to breathe with the light, changing its appearance according to the viewer’s angle and the sun’s movement throughout the day.

The Magic in the Details: When the Machine Achieves What the Hand Cannot

The true magic of the CeraShingle project lies not only in the final result but in the manufacturing process itself.

Robotic arms handle the clay slowly and precisely, layering it to create surface details impossible to achieve using molds or traditional techniques.

Beauty Revealed with Light

Imagine delicate ridges capturing shadows with every shift in the sun’s angle, subtle engravings that appear only at specific moments of the day, and soft curves that exceed the limits of what can be pressed or cast by hand.

In this way, the clay transforms into a living material that interacts with light and time, blending mechanical precision with artistic sensibility.

Parametric Design: Diversity Within a System

Through a workflow based on Parametric Design, each element of the façade can be controlled with geometric precision.

Every shingle is unique, varying in thickness, texture, and curvature, yet perfectly harmonizes with the surrounding pieces during installation.

It is a rare balance between individuality and system, opening the door to a new generation of façades that merge traditional craftsmanship with artificial intelligence.

Surpassing the Digital-Craft Dichotomy

What stands out most in the CeraShingle project is that it does not fall into the traditional debate between digital and handcrafted work.

Instead of viewing technology as a replacement for humans, the project employs it as a tool to enhance the essence of craft itself, the sensory and spiritual dimension that allows ceramics to express humanity before it expresses the machine.

Technology as an Extension of the Human Hand

In this context, the robot is not seen as an adversary to the artisan but as an extension of human capabilities.

It does not eliminate the human touch; rather, it expands its possibilities, enabling the execution of complex details that were once limited to imagination or chance.

Through this interplay, a new relationship emerges between digital precision and material intimacy, where the clay retains its warmth even as it is shaped by a machine.

Art That Inspires, Not Competes

Perhaps the greatness of this project lies in its refusal to replace humans with machines, aiming instead for a reconciliation between the two.

It offers an aesthetic experience that leaves traditional artisans not feeling threatened, but amazed and inspired by what craft can achieve when it converges with modern technology.

Environmental Value at the Heart of Design

The appeal of the CeraShingle project goes beyond its visual beauty or innovative techniques; it extends to its environmentally conscious story.

It demonstrates that architectural creativity can also be eco-friendly without compromising aesthetics or performance.

Technology That Reduces Waste and Rethinks Production

Through 3D printing, materials are used only where they are precisely needed, significantly reducing material waste compared to traditional methods that rely on carving or subtractive processes.

This precision in resource usage represents a shift toward more sustainable design and smarter material consumption.

Local Materials and Calculated Sustainability

Designers Yutao Chen and Yiwen Gu utilize locally sourced clay and low-temperature glazes, a choice that reduces transportation costs and energy consumption during firing.

Using local resources also reinforces the project’s sense of place, rooting it in its environment rather than making it feel alien.

Design That Can Be Repaired, Not Disposed Of

When a façade unit is damaged, only the affected piece needs to be replaced, without dismantling the entire panel.

This approach not only extends the façade’s lifespan but also limits the carbon emissions associated with maintenance and subsequent production.

Small Details, Big Impact

In a world where construction contributes roughly 40% of global carbon emissions, initiatives like this represent tangible steps toward change.

They remind us that sustainability is achieved not only through materials or technology but also through conscious design thinking that balances beauty and responsibility.

A New Aesthetic Language in Contemporary Architecture

The CeraShingle project goes beyond being a mere technical solution, becoming an innovative aesthetic expression.

Traditional architectural cladding often falls at opposite ends of a spectrum:

- Shiny industrial materials such as glass and metal, or

- Traditional materials like stone and brick that evoke the past and reconnect us with heritage.

CeraShingle occupies a third space, clearly producing a contemporary language that leverages digital tools and computational thinking, while simultaneously preserving the warmth of time-honored ceramics.

In this way, it achieves a rare balance between technical precision and artisanal sensibility, giving it a sculpted character without exaggeration, and a technical edge without coldness.

Flexibility and Expansion Through Parametric Logic

The system also boasts high adaptability and scalability.

It can be applied to small installations, a feature wall, or even the full façade of a building, while maintaining simplicity in installation and maintenance.

Using modular parametric logic, projects can grow organically, making CeraShingle an example of design flexibility that harmonizes innovation with practical considerations.

CeraShingle: Between Heritage and Modernity

The CeraShingle project is set to launch in 2026, at a moment that appears pivotal for contemporary architecture.

Today, the world is witnessing a renewed interest in craft and materiality after decades dominated by sleek minimalism and extreme simplicity.

People are seeking texture, surfaces that respond to light and touch, and buildings that feel like living entities rather than mere closed boxes.

Balancing Sensation and Performance

At the same time, climate considerations impose new demands, pushing architecture toward lighter, more efficient systems.

Here, CeraShingle emerges as an innovative solution, weaving a balance between:

- The rich tactile experience of traditional materials, and

- The performance and flexibility of modern systems.

An Architectural Façade That Interacts with the Environment

The result is a façade that interacts with light and time, changing according to angles and the sun’s movement, yet remaining connected to the essence of earth and fire from which ceramics have been born for millennia.

In this way, the project offers an architectural experience that merges authenticity with technological creativity, opening the door to a new generation of living and sustainable façades.

CeraShingle: Between Contemplation and Challenge

What Yutao Chen and Yiwen Gu have created is more than just an intelligent product; it represents an invitation to reflect on the future of architecture.

The project poses a fundamental question:

What if we stopped seeing digital fabrication as a replacement for handcrafted work and began to view it as the next chapter in the evolution of craftsmanship?

Interaction with Light and Space

The answer becomes clear when witnessing the results in reality, especially when the façade envelops a building and captures the afternoon light.

In this way, the project offers a sensory and aesthetic experience that could inspire the future of building cladding, making façades more responsive to light and time while preserving the essence of traditional materials.

✦ ArchUp Editorial Insight

The CeraShingle project presents an intriguing model for integrating traditional craftsmanship with digital technologies, demonstrating high manufacturing precision and the ability to diversify elements parametrically. These capabilities give designers and developers the opportunity to explore façade forms that were impossible using conventional methods, opening the door to sensory experiences that interact with light and the environment.

However, the project remains limited in several ways when viewed from a practical architectural perspective. First, the focus on 3D printing and the use of locally sourced clay makes both initial and operational costs relatively high compared to traditional façades, potentially restricting its application in large-scale or standard residential projects. Second, the heavy reliance on robotic arms and parametric design requires advanced expertise from designers and engineers, which may make it difficult to scale the project in less specialized markets or design teams. Third, despite its sustainability features, routine maintenance and handling of clay and ceramics in diverse environments pose challenges that require long-term study to ensure performance durability under varying weather conditions.

Conversely, the project can serve as a case study or experimental model for new architectural ideas, particularly in projects that require interactive façades or educational and cultural buildings, where artistic innovation and sensory experience can be combined with modern design technologies. CeraShingle can also inspire architects to develop hybrid solutions that merge digital precision with the artisanal touch, while taking practical and economic constraints into account.

Prepared by the ArchUp Editorial Team

Don’t miss the chance to explore more from Architecture, Projects, and Interior Design on the ArchUp website.