Composite Columns Merging Strength and Flexibility in Modern Architecture

In the world of construction, columns are not only judged by their load-bearing capacity but also by their ability to adapt to the challenges of contemporary architectural design. Among various column types, composite columns have emerged as a smart engineering solution that combines the rigidity of concrete with the strength of steel, offering buildings greater stability, reduced costs, and more efficient structural details.

Historical Roots Before They Had a Name

Although composite columns were not explicitly mentioned in classical architecture textbooks, their use appeared implicitly in Roman-era structures and facades. However, they began to be used as an explicit structural concept beginning with the Renaissance, especially with the architect Palladio, and later in the Baroque style and in many historical buildings.

With industrial development, composite materials expanded beyond stone and wood to include reinforced concrete, metals, and synthetic fibers opening up new possibilities for bold architectural projects.

| Period | Notable Uses |

|---|---|

| Roman | Arch of Titus – Petra |

| Renaissance | Palladio’s Columns |

| Baroque | Louvre Museum |

| 20th Century | Concrete and Steel |

| Late 20th C. | Japan & USA – High-Performance Composite Sections |

What Exactly Are Composite Columns?

Composite columns are structural elements made from a combination of building materials most commonly concrete and steel. They are designed to take advantage of each material’s unique strengths.

- Concrete excels at resisting compression forces

- Steel performs well under tension and bending

This combination results in a stronger, lighter, and more efficient structural component than when either material is used alone.

Applications and Dimensions

Engineers widely use composite columns in a variety of projects — including high-rise buildings, commercial centers, bridges, and industrial facilities.

| Parameter | Details |

|---|---|

| Spans | 2 – 6 meters |

| Common Sizes | 22.5 × 22.5 cm |

| Floors Used | One or more floors, depending on design |

Behavior Under Load

Composite columns primarily handle axial loads , whether compressive or tensile. Thanks to the effective integration of materials, they also perform well under bending stresses. This balanced stress distribution ensures high efficiency without requiring oversized sections or excessive reinforcement.

Types of Composite Columns

- Concrete-Filled Steel Tubes (CFST)

Engineers construct composite columns by filling hollow steel tubes with concrete, combining materials to boost strength and reduce deformation. - Steel Sections Encased in Concrete

The steel section is partially or fully encased in concrete, offering protection against fire and corrosion. This type is commonly used in multi-story buildings.

Execution Steps

The construction process of composite columns involves several precise stages to ensure quality:

- Fixing the steel section in place

- Ensuring proper bracing and alignment

- Pouring concrete around the steel element

- Proper curing to achieve full bond between materials

Strengthening Columns with Concrete Jackets

When a column is damaged or needs to carry additional loads, it can be strengthened using a concrete jacket :

- Remove plaster and clean the surface

- Drill holes and install new rebars with epoxy

- Pour new concrete using shotcrete or traditional formwork

- In case of rust damage, remove deteriorated concrete, treat the steel, then pour the new jacket

Structural Calculations

Engineers calculate the ultimate load capacity of a composite column using the following formula:

1

Qu × 10³ = 0.35Ac Fcu + 0.67As Fy

Where:

- Ac = Area of concrete

- As = Area of steel reinforcement

- Fcu = Compressive strength of concrete

- Fy = Tensile strength of steel

Types of Connections

Engineers use appropriate connections to ensure optimal performance of composite columns.

| Type | Function |

|---|---|

| Rigid Connections | Transfer full load directly |

| Semi-Rigid | Absorb part of the load, reduce stress |

| Bonded Joints | Rely on adhesion between concrete and steel |

Advantages and Disadvantages

Advantages:

- High strength-to-weight ratio

- Design flexibility and ease of shaping

- Excellent resistance to deformation and bending

- Reduced number of structural components

- Easy maintenance and replacement

Disadvantages:

- Lower ductility ompared to solid metal sections

- Require specialized skills for installation and repair

- Sensitive to moisture and temperature changes

- Repair costs may be relatively high

Conclusion

Composite columns represent an advanced phase in structural thinking. Rather than viewing materials separately, engineers now combine them intelligently to create stronger, smarter buildings. Their use has evolved from a luxury into a necessity for projects aiming to balance efficiency, aesthetics, and sustainability.

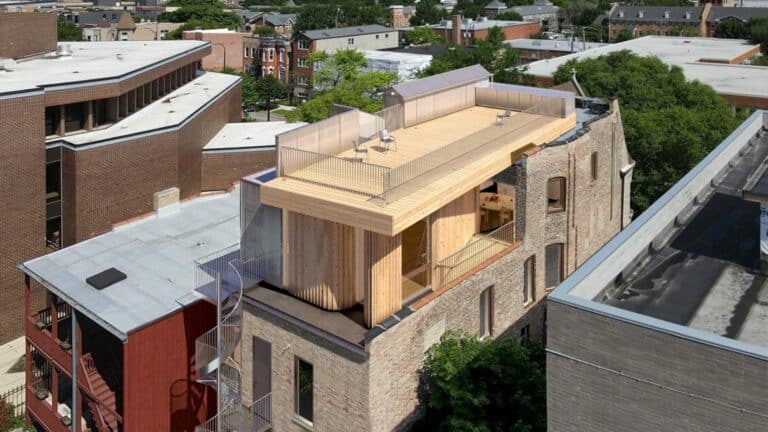

ArchUp continues to track shifts in the construction industry by showcasing innovative projects that actively reshape urban development.