A constructing challenge in Wuhan China, visibly demonstrating the connection between the interior load-bearing construction and an exterior glass curtain wall

Curtain partitions are additionally used on residential buildings

A curtain wall is an outer protecting of a constructing by which the outer partitions are non-structural, utilized solely to maintain the climate out and the occupants in. For the reason that curtain wall is non-structural, it may be manufactured from light-weight supplies, equivalent to glass, thereby doubtlessly decreasing building prices. An extra benefit of glass is that pure mild can penetrate deeper inside the constructing. The curtain wall façade doesn’t carry any structural load from the constructing aside from its personal useless load weight. The wall transfers lateral wind hundreds which are incident upon it to the principle constructing construction by way of connections at flooring or columns of the constructing. A curtain wall is designed to withstand air and water infiltration, take up sway induced by wind and seismic forces performing on the constructing, face up to wind hundreds, and help its personal weight

Curtain partitions could also be designed as “methods” integrating body, wall panel, and weatherproofing supplies. Metal frames have largely given strategy to aluminum extrusions, sometimes infilled with glass, which supplies an architecturally pleasing look and advantages equivalent to daylighting. Nonetheless, the consequences of sunshine on visible consolation in addition to photo voltaic warmth acquire in a constructing are harder to regulate when utilizing giant quantities of glass infill. Different widespread infills embrace stone veneer, metallic panels, louvres, and operable home windows or vents.

Curtain wall methods differ from storefront methods in being designed to span a number of flooring, taking into account constructing sway and motion along with design necessities equivalent to thermal enlargement and contraction; seismic necessities, water diversion; and thermal effectivity for cost-effective heating, cooling, and inside lighting.

Historical past

Inbuilt 1864, Oriel Chambers, Liverpool, England, the primary constructing that includes a metal-framed glass curtain wall

16 Cook dinner Road, Liverpool, 1866. In depth use is manufactured from floor-to-ceiling glass, enabling mild to penetrate deeper into the constructing, thus maximizing flooring area.

Glass curtain wall of the Bauhaus Dessau, 1926

Traditionally, buildings had been constructed of timber, masonry, or a mix of each.

Their exterior partitions had been load bearing, supporting a lot or the entire load of the whole construction. The character of the supplies resulted in inherent limits to a constructing’s peak.

The event and widespread use of structural metal and later strengthened concrete allowed comparatively small columns to help giant hundreds. The outside partitions may very well be non-load bearing, and thus a lot lighter and extra open than load-bearing partitions of the previous. This gave strategy to elevated use of glass as an exterior façade, and the modern-day curtain wall was born.

Put up and beam and balloon framed timber buildings successfully had an early model of curtain partitions, as their frames supported hundreds that allowed the partitions themselves to serve different capabilities, equivalent to retaining climate out and permitting mild in. When iron started for use extensively in buildings in late 18th-century Britain, equivalent to at Ditherington Flax Mill, and later when buildings of wrought iron and glass equivalent to The Crystal Palace had been constructed, the constructing blocks of structural understanding had been laid for the event of curtain partitions.

Oriel Chambers (1864) and 16 Cook dinner Road (1866), each inbuilt Liverpool, England, by native architect and civil engineer Peter Ellis, are characterised by their in depth use of glass of their facades. In the direction of the courtyards they even boasted metal-framed glass curtain partitions, which makes them two of the world’s first buildings to incorporate this architectural function.[1] The in depth glass partitions allowed mild to penetrate additional into the constructing, using extra flooring area and decreasing lighting prices. Oriel Chambers includes 43,000 sq ft (4,000 m2) set over 5 flooring with out an elevator, which had solely lately been invented and was not but widespread.[2] The Statue of Liberty (1886) contains a skinny, non-load-bearing copper pores and skin.

An early instance of an all-steel curtain wall used within the classical fashion is the Kaufhaus Tietz division retailer on Leipziger Straße, Berlin, inbuilt 1901 (since demolished).[3]

Among the first curtain partitions had been made with metal mullions, and the polished plate glass was hooked up to the mullions with asbestos- or fiberglass-modified glazing compound. Finally silicone sealants or glazing tape had been substituted for the glazing compound. Some designs included an outer cap to carry the glass in place and to guard the integrity of the seals. The primary curtain wall put in in New York Metropolis, within the United Nations Secretariat Constructing (Skidmore, Owings, and Merrill, 1952), was the sort of building. Earlier modernist examples are the Bauhaus in Dessau (1926) and the Hallidie Constructing in San Francisco (1918).

Ludwig Mies van der Rohe’s curtain wall is likely one of the most essential facet of his architectural design. Mies first started prototyping the curtain wall in his high-rise residential constructing designs alongside Chicago’s lakeshore, reaching the look of a curtain wall at famed 860-880 Lake Shore Drive Flats. He lastly perfected the curtain wall at 900 910 Lake Shore Drive, the place the curtain is an autonomous aluminum and glass pores and skin. After 900 910, Mies’ curtain wall appeared on all of his subsequent high-rise constructing designs together with the famed Seagram constructing in New York.

https://archup.web/rain-curtain-house-room11-architects/

In the course of the Seventies, the widespread use of aluminium extrusions for mullions started. Aluminum alloys provide the distinctive benefit of having the ability to be simply extruded into practically any form required for design and aesthetic functions. In the present day, the design complexity and shapes out there are practically limitless. Customized shapes might be designed and manufactured with relative ease. The Omni San Diego Resort curtain wall in California, designed by architectural agency Hornberger and Worstel and developed by JMI Realty, is an instance of a unitized curtain-wall system with built-in sunshades.[4]

Techniques and ideas

Stick methods

The overwhelming majority of ground-floor curtain partitions are put in as lengthy items (known as sticks) between flooring vertically and between vertical members horizontally. Framing members could also be fabricated in a store, however set up and glazing is often carried out on the jobsite.

Ladder methods

Similar to a stick system, a ladder system has mullions which might be cut up after which both snapped or screwed collectively consisting of a half field and plate. This enables sections of curtain wall to be fabricated in a store, successfully decreasing the time spent putting in the system on web site. The drawbacks of utilizing such a system is lowered structural efficiency and visual joint traces down the size of every mullion.

Unitized methods

Unitized curtain partitions entail manufacturing unit fabrication and meeting of panels and should embrace manufacturing unit glazing. These accomplished items are put in on the constructing construction to type the constructing enclosure. Unitized curtain wall has the benefits of: pace; decrease area set up prices; and high quality management inside an inside climate-controlled atmosphere. The financial advantages are sometimes realized on giant tasks or in areas of excessive area labor charges.

Rainscreen precept

A standard function in curtain wall know-how, the rainscreen precept theorizes that equilibrium of air strain between the inside and outside of the “rainscreen” prevents water penetration into the constructing. For instance, the glass is captured between an interior and an outer gasket in an area known as the glazing rebate. The glazing rebate is ventilated to the outside in order that the strain on the interior and outer sides of the outer gasket is identical. When the strain is equal throughout this gasket, water can’t be drawn by way of joints or defects within the gasket.

Design issues

A curtain wall system should be designed to deal with all hundreds imposed on it in addition to maintain air and water from penetrating the constructing envelope.

Hundreds

The hundreds imposed on the curtain wall are transferred to the constructing construction by way of the anchors which connect the mullions to the constructing.

- Lifeless load

Lifeless load is outlined as the burden of structural parts and the everlasting options on the construction.[5] Within the case of curtain partitions, this load is made up of the burden of the mullions, anchors and different structural elements of the curtain wall, in addition to the burden of the infill materials. Extra useless hundreds imposed on the curtain wall could embrace sunshades or signage hooked up to the curtain wall.

- Wind load

Wind load is a standard pressure performing on the constructing as the results of wind blowing on the constructing.[6] Wind strain is resisted by the curtain wall system because it envelops and protects the constructing. Wind hundreds range tremendously all through the world, with the most important wind hundreds being close to the coast in hurricane-prone areas. For every challenge location, constructing codes specify the required design wind hundreds. Typically, a wind tunnel research is carried out on giant or unusually-shaped buildings. A scale mannequin of the constructing and the encircling neighborhood is constructed and positioned in a wind tunnel to find out the wind pressures performing on the construction in query. These research take note of vortex shedding round corners and the consequences of surrounding topography and buildings.

- Seismic load

Seismic hundreds in curtain wall system are restricted to the interstory drift induced on the constructing throughout an earthquake. In most conditions, the curtain wall is ready to naturally face up to seismic and wind induced constructing sway due to the area supplied between the glazing infill and the mullion. In exams, normal curtain wall methods are sometimes capable of face up to as much as three inches (75 mm) of relative flooring motion with out glass breakage or water leakage.

- Snow load

Snow hundreds and stay hundreds aren’t sometimes a difficulty in curtain partitions, since curtain partitions are designed to be vertical or barely inclined. If the slope of a wall exceeds 20 levels or so, these hundreds could should be thought of.[7]

- Thermal load

Thermal hundreds are induced in a curtain wall system as a result of aluminum has a comparatively excessive coefficient of thermal enlargement. Because of this over the span of a few flooring, the curtain wall will broaden and contract a long way, relative to its size and the temperature differential. This enlargement and contraction is accounted for by slicing horizontal mullions barely brief and permitting an area between the horizontal and vertical mullions. In unitized curtain wall, a niche is left between items, which is sealed from air and water penetration by gaskets. Vertically, anchors carrying wind load solely (not useless load) are slotted to account for motion. By the way, this slot additionally accounts for stay load deflection and creep within the flooring slabs of the constructing construction.

- Blast load

Unintentional explosions and terrorist threats have introduced on elevated concern for the fragility of a curtain wall system in relation to blast hundreds. The bombing of the Alfred P. Murrah Federal Constructing in Oklahoma Metropolis, Oklahoma, has spawned a lot of the present analysis and mandates with reference to constructing response to blast hundreds. At present, all new federal buildings within the U.S. and all U.S. embassies constructed on international soil will need to have some provision for resistance to bomb blasts.[8]

For the reason that curtain wall is on the exterior of the constructing, it turns into the primary line of protection in a bomb assault. As such, blast resistant curtain partitions are designed to resist such forces with out compromising the inside of the constructing to guard its occupants. Since blast hundreds are very excessive hundreds with brief durations, the curtain wall response ought to be analyzed in a dynamic load evaluation, with full-scale mock-up testing carried out previous to design completion and set up.

Blast resistant glazing consists of laminated glass, which is supposed to interrupt however not separate from the mullions. Related know-how is utilized in hurricane-prone areas for affect safety from wind-borne particles.

Air Infiltration

Air infiltration is the air which passes by way of the curtain wall from the outside to the inside of the constructing. The air is infiltrated by way of the gaskets, by way of imperfect joinery between the horizontal and vertical mullions, by way of weep holes, and thru imperfect sealing. The American Architectural Producers Affiliation (AAMA) is an trade commerce group within the U.S. that has developed voluntary specs concerning acceptable ranges of air infiltration by way of a curtain wall.[9]

Water penetration

Water penetration is outlined as water passing from the outside of the constructing to the inside of the curtain wall system. Generally, relying on the constructing specs, a small quantity of managed water on the inside is deemed acceptable. Managed water penetration is outlined as water that penetrates past the interior most vertical aircraft of the take a look at specimen, however has a designed technique of drainage again to the outside. AAMA Voluntary Specs enable for managed water penetration whereas the underlying ASTM E1105 take a look at methodology would outline such water penetration as a failure. To check the flexibility of a curtain wall to resist water penetration within the area, an ASTM E1105 water spray rack system is positioned on the outside facet of the take a look at specimen, and a constructive air strain distinction is utilized to the system. This arrange simulates a wind pushed rain occasion on the curtain wall to examine for area efficiency of the product and of the set up. Area high quality management and assurance checks for water penetration has turn out to be the norm as builders and installers apply such high quality applications to assist scale back the variety of water injury litigation fits in opposition to their work.

Deflection

One of many disadvantages of utilizing aluminum for mullions is that its modulus of elasticity is about one-third that of metal. This interprets to a few instances extra deflection in an aluminum mullion in comparison with an analogous metal part beneath a given load. Constructing specs set deflection limits for perpendicular (wind-induced) and in-plane (useless load-induced) deflections. These deflection limits aren’t imposed as a result of energy capacities of the mullions. Slightly, they’re designed to restrict deflection of the glass (which can break beneath extreme deflection), and to make sure that the glass doesn’t come out of its pocket within the mullion. Deflection limits are additionally crucial to regulate motion on the inside of the curtain wall. Constructing building could also be such that there’s a wall situated close to the mullion, and extreme deflection could cause the mullion to contact the wall and trigger injury. Additionally, if deflection of a wall is sort of noticeable, public notion could elevate undue concern that the wall isn’t sturdy sufficient.

Deflection limits are sometimes expressed as the gap between anchor factors divided by a continuing quantity. A deflection restrict of L/175 is widespread in curtain wall specs, primarily based on expertise with deflection limits which are unlikely to trigger injury to the glass held by the mullion. Say a given curtain wall is anchored at 12 foot (144 in) flooring heights. The allowable deflection would then be 144/175 = 0.823 inches, which suggests the wall is allowed to deflect inward or outward a most of 0.823 inches on the most wind strain. Nonetheless, some panels require stricter motion restrictions, or actually people who prohibit a torque-like movement.

Deflection in mullions is managed by completely different shapes and depths of curtain wall members. The depth of a given curtain wall system is normally managed by the world second of inertia required to maintain deflection limits beneath the specification. One other strategy to restrict deflections in a given part is so as to add metal reinforcement to the within tube of the mullion. Since metal deflects at one-third the speed of aluminum, the metal will resist a lot of the load at a decrease value or smaller depth.

Power

Power (or most usable stress) out there to a specific materials isn’t associated to its materials stiffness (the fabric property governing deflection); it’s a separate criterion in curtain wall design and evaluation. This usually impacts the collection of supplies and sizes for design of the system. The allowable bending energy for sure aluminum alloys, equivalent to these sometimes utilized in curtain wall framing, approaches the allowable bending energy of metal alloys utilized in constructing building.

Thermal standards

Condensation varieties on the glass curtain wall

Relative to different constructing elements, aluminum has a excessive warmth switch coefficient, that means that aluminum is an excellent conductor of warmth. This interprets into excessive warmth loss by way of aluminum curtain wall mullions.

There are a number of methods to compensate for this warmth loss, the most typical manner being the addition of thermal breaks. Thermal breaks are boundaries between exterior metallic and inside metallic, normally manufactured from polyvinyl chloride (PVC). These breaks present a major lower within the thermal conductivity of the curtain wall. Nonetheless, for the reason that thermal break interrupts the aluminum mullion, the general second of inertia of the mullion is lowered and should be accounted for within the structural evaluation and deflection evaluation of the system.

Thermal conductivity of the curtain wall system is essential due to warmth loss by way of the wall, which impacts the heating and cooling prices of the constructing. On a poorly performing curtain wall, condensation could type on the inside of the mullions. This might trigger injury to adjoining inside trim and partitions.

Inflexible insulation is supplied in spandrel areas to supply the next R-value at these areas.

Infills

Infill refers back to the giant panels which are inserted into the curtain wall between mullions. Infills are sometimes glass however could also be made up of practically any exterior constructing factor. Some widespread infills embrace metallic panels, louvers, and photovoltaic panels.

Glass

Glass curtain wall on the lodge Andaz in Singapore at sundown

Float glass is by far the most typical curtain wall glazing sort. It may be manufactured in an nearly infinite mixture of coloration, thickness, and opacity. For business building, the 2 commonest thicknesses are 1/4 inch (6 mm) monolithic and 1 inch (25 mm) insulating glass. 1/4 inch glass is often used solely in spandrel areas, whereas insulating glass is used for the remainder of the constructing (typically spandrel glass is specified as insulating glass as properly). The 1 inch insulation glass is often made up of two 1/4-inch lites of glass with a 1/2 inch (12 mm) airspace. The air inside is normally atmospheric air, however some inert gases, equivalent to argon or krypton could also be used to supply higher thermal transmittance values. In Europe, triple-pane insulating glass infill is now widespread. In Scandinavia first curtain partitions with quadruple-pane have been constructed.

Bigger thicknesses are sometimes employed for buildings or areas with greater thermal, relative humidity, or sound transmission necessities, equivalent to laboratory areas or recording studios. In residential building, thicknesses generally used are 1/8 inch (3 mm) monolithic and 5/8 inch (16 mm) insulating glass.

Glass could also be used which is clear, translucent, or opaque, or in various levels thereof. Clear glass normally refers to imaginative and prescient glass in a curtain wall. Spandrel or imaginative and prescient glass may additionally include translucent glass, which may very well be for safety or aesthetic functions. Opaque glass is utilized in areas to cover a column or spandrel beam or shear wall behind the scenes wall. One other methodology of hiding spandrel areas is thru shadow field building (offering a darkish enclosed area behind the clear or translucent glass). Shadow field building creates a notion of depth behind the glass that’s typically desired.

Cloth veneer

Cloth is one other sort of fabric which is widespread for curtain partitions. Cloth is usually a lot cheaper and serves as a much less everlasting resolution. Not like glass or stone, material is far sooner to put in, cheaper, and sometimes a lot simpler to switch after it’s put in.

Due to low density of materials whole weight of construction could be very low then energy consideration of construction isn’t too essential.

Stone veneer

Skinny blocks (3 to 4 inches (75–100 mm)) of stone might be inset inside a curtain wall system. The kind of stone used is proscribed solely by the energy of the stone and the flexibility to fabricate it within the correct form and dimension. Frequent stone sorts used are: calcium silicate, granite, marble, travertine, limestone, and engineered stone. To scale back weight and enhance energy, the pure stone could also be hooked up to an aluminum honeycomb backing.

Panels

Steel panels can take varied varieties together with chrome steel, aluminum plate; aluminum composite panels consisting of two skinny aluminum sheets sandwiching a skinny plastic interlayer; copper wall cladding, and panels consisting of metallic sheets bonded to inflexible insulation, with or with out an interior metallic sheet to create a sandwich panel. Different opaque panel supplies embrace fiber-reinforced plastic (FRP) and terracotta. Terracotta curtain wall panels had been first utilized in Europe, however just a few producers produce top quality fashionable terracotta curtain wall panels.

Louvers

A louver is supplied in an space the place mechanical gear situated contained in the constructing requires air flow or recent air to function. They’ll additionally function a way of permitting exterior air to filter into the constructing to make the most of favorable weather conditions and decrease the utilization of energy-consuming HVAC methods. Curtain wall methods might be tailored to just accept most forms of louver methods to take care of the identical architectural sightlines and elegance whereas offering desired performance.

Home windows and vents

Most curtain wall glazing is mounted, that means there isn’t any entry to the outside of the constructing besides by way of doorways. Nonetheless, home windows or vents might be glazed into the curtain wall system as properly, to supply required air flow or operable home windows. Almost any window sort might be made to suit right into a curtain wall system.

Hearth security

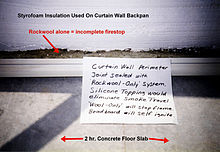

Flamable polystyrene insulation in level contact with sheet metallic backban. Incomplete firestop within the perimeter slab edge, manufactured from rockwool with out topcaulking.

Firestopping on the perimeter slab edge, which is a niche between the ground and the curtain wall, is crucial to sluggish the passage of fireplace and combustion gases between flooring. Spandrel areas will need to have non-combustible insulation on the inside face of the curtain wall. Some constructing codes require the mullion to be wrapped in heat-retarding insulation close to the ceiling to stop the mullions from melting and spreading the hearth to the ground above. The firestop on the perimeter slab edge is taken into account a continuation of the fire-resistance ranking of the ground slab. The curtain wall itself, nevertheless, isn’t ordinarily required to have a ranking. This causes a quandary as compartmentalization (fireplace safety) is often primarily based upon closed compartments to keep away from fireplace and smoke migrations past every engaged compartment. A curtain wall by its very nature prevents the completion of the compartment (or envelope). Using fireplace sprinklers has been proven to mitigate this matter. As such, until the constructing is sprinklered, fireplace should journey up the curtain wall, if the glass on the uncovered flooring is shattered from warmth, inflicting flames to lick up the skin of the constructing.

Falling glass can endanger pedestrians, firefighters and firehoses beneath. An instance of that is the 1988 First Interstate Tower fireplace in Los Angeles, California. The hearth leapfrogged up the tower by shattering the glass after which consuming the aluminum framing holding the glass.[10] Aluminum’s melting temperature is 660 °C, whereas constructing fires can attain 1,100 °C. The melting level of aluminum is often reached inside minutes of the beginning of a hearth.

Fireman knock-out glazing panels are sometimes required for venting and emergency entry from the outside. Knock-out panels are usually totally tempered glass to permit full fracturing of the panel into small items and comparatively protected removing from the opening.

Upkeep and restore

Curtain partitions and perimeter sealants require upkeep to maximise service life. Perimeter sealants, correctly designed and put in, have a typical service lifetime of 10 to fifteen years. Removing and alternative of perimeter sealants require meticulous floor preparation and correct detailing.

Aluminum frames are usually painted or anodized. Care should be taken when cleansing areas round anodized materials as some cleansing brokers will destroy the end. Manufacturing unit utilized fluoropolymer thermoset coatings have good resistance to environmental degradation and require solely periodic cleansing. Recoating with an air-dry fluoropolymer coating is feasible however requires particular floor preparation and isn’t as sturdy because the baked-on unique coating. Anodized aluminum frames can’t be “re-anodized” in place however might be cleaned and guarded by proprietary clear coatings to enhance look and sturdiness.

https://archup.web/the-most-important-conditions-for-interior-design/

Stainless-steel curtain partitions require no coatings, and embossed, versus abrasively completed, surfaces keep their unique look indefinitely with out cleansing or different upkeep. Some specifically textured matte chrome steel floor finishes are hydrophobic and resist airborne and rain-borne pollution.[11] This has been invaluable within the American Southwest and within the Mideast for avoiding mud, in addition to avoiding soot and smoke staining in polluted city areas.

See additionally

- Mullion wall

- Insulated glazing

- Quadruple glazing

- Copper in structure

- European Fee’s portal for environment friendly Curtain Walling Archived 23 September 2015 on the Wayback Machine

- EN 13830: Curtain Walling – Product Commonplace

- EN 13119: Curtain Walling – Terminology

- Understanding Curtain Wall & Window Wall variations