KUJIETOOL: Precision and Creativity for Work in Small Spaces

Challenges of Precision in Small Spaces

Designers and innovators often face a significant challenge when working with precision in confined spaces. Typically, high-precision operations require large, complex industrial equipment, which increases costs and limits the feasibility of working in a small home or office environment.

Small and Precise Solutions

Miniaturized solutions offer practical alternatives to this problem. For instance, some desktop milling machines provide access to high precision of up to 0.01 mm, while maintaining dimensions and weight suitable for placement on any desk without requiring extensive space or additional setups.

Rethinking Creative Work

This type of device fundamentally changes the way innovators approach intricate projects. It allows them to work with greater flexibility and efficiency, enabling complex operations to be carried out in a personal environment without relying on large industrial workshops or expensive equipment.

Design and Engineering Precision

Compact and streamlined design stands out as a key factor in the usability of desktop milling machines. Despite their small size and lightweight construction, these devices deliver serious milling capabilities, reflecting the power of innovation to integrate high performance within a compact package.

Materials and Build Quality

These machines often rely on high-strength aluminum alloys, providing remarkable durability despite their light weight. This quality of construction underscores attention to engineering precision, an essential trait for any machine intended for fine, creative work.

Balancing Size and Performance

Here lies the core challenge: achieving a balance between the device’s size and its performance. Lightweight construction and precise engineering do not mean compromising on accuracy or the ability to execute complex milling operations. On the contrary, they enable innovators to work efficiently within a limited space without the need for bulky equipment.

Innovation in Ultra-Precision

True innovation is evident in the ability of desktop milling machines to deliver professional-level precision within a compact device. High accuracy is no longer exclusive to large industrial equipment; it can now be achieved within a limited office environment.

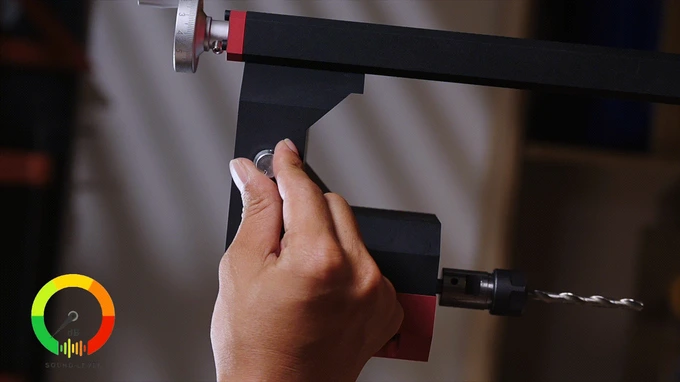

Manual Control and Fine Adjustment

Each manual dial on the X, Y, and Z axes features graduated increments as fine as 0.007 mm per division, allowing users to make precise adjustments with high confidence. This level of control enhances the capability to perform complex tasks requiring exceptional accuracy without relying on bulky or expensive equipment.

Overall Precision Level

Specifications indicate that the overall precision reaches ±0.01 mm, enabling intricate milling operations with efficiency comparable to traditional industrial machines. This feature makes it possible to rethink the design of small creative projects and execute them with flexibility and efficiency.

Spindle Speed Control

The stepless spindle speed control feature plays a crucial role in enhancing the flexibility of precision milling operations. This system allows variable speeds ranging from 0 to 10,000 RPM, with the ability to rotate forward or backward as needed.

Adaptation to Different Materials

This flexibility enables adaptation to a wide variety of materials, from thin plastics and robust aluminum to traditional wood. Precise spindle control allows for meticulous operations without risking material damage or loss of accuracy, an essential factor when handling projects that require diverse materials.

Enhancing Efficiency and Accuracy

By adjusting the spindle speed according to the material type and nature of the operation, work efficiency and final cutting accuracy can be optimized. This adaptability makes it possible to manage complex projects within a small workspace without the need for additional large-scale equipment.

Modular Design Philosophy

The modular design philosophy is a defining feature of desktop milling machines, setting them apart from traditional tools in terms of flexibility and upgradability. The adjustable structure allows users to adapt the device as their skills and project needs evolve, without starting from scratch when improvements or expansions are required.

Adapting to Project Evolution

This carefully engineered approach reflects the ability to add accessories or modify device components with ease. Maintenance points are designed to be easily accessible, facilitating long-term upkeep and efficient operation.

Flexibility and Expandability

Expandable tool options make the machine more versatile, enabling innovators to experiment with different materials and techniques without the need for additional bulky or complex equipment. This approach underscores the importance of smart design that combines precision with the ability to adapt to future projects.

Impact of Compact Design on Work Style

The compact size of the device plays a significant role in redefining how precision tasks are executed. Instead of relying on project schedules dictated by workshop availability, work can now begin as soon as a new idea emerges, enhancing creativity and flexibility in managing time and projects.

Portability and Sharing

Portability allows the device to be easily used in different locations, whether sharing it with colleagues, moving it between workplaces, or even utilizing it during on-site meetings to create prototypes directly on location. This flexibility makes it possible to integrate precise creative work into various environments without the need for large, heavy equipment.

Boosting Creative Productivity

By enabling work anytime and anywhere, innovators can test ideas more quickly and make immediate adjustments, improving the quality of final results and shortening the project development cycle.

Practical Applications in Confined Environments

The value of desktop milling machines becomes clear when dealing with scenarios where traditional equipment is impractical. They enable users to perform precise tasks within a limited space, without relying on large workshops or heavy machinery.

Working on Prototypes

For instance, when designing a prototype for a new product, a designer may need to mill custom brackets or covers with high precision. Desktop machines provide the capability to carry out these operations repeatedly, allowing for easy assembly testing and adjustments without space or equipment constraints.

Improving the Development Cycle

This flexibility enables designers to test ideas more quickly, accelerating the project development cycle and enhancing the quality of prototypes before moving on to final production.

The Importance of Accessibility in Education

For teachers and students, accessibility becomes a crucial factor. Tools that are easy to access allow the demonstration of precision machining concepts within classrooms, where traditional machines cannot adapt to space constraints or strict safety requirements.

Enhancing Hands-On Experience

Moreover, these tools provide practical learning experiences that were previously impossible. Space limitations or potential hazards often restrict the use of conventional equipment, but innovative design opens the door for students to engage directly with concepts in a safe and effective manner.

Ease of Use While Maintaining Precision

In addition, intuitive controls ensure that beginners can use the device easily while maintaining the level of precision required by experienced makers. Thus, the machine combines hands-on learning with user-friendliness, creating a rich and versatile educational environment.

Anticipating the Future Needs of Makers

What truly sets this milling machine apart is its ability to adapt to the evolving needs of today’s makers. Even if you start with simple tasks such as prototyping, the device can grow alongside your projects, offering more complex operational capabilities as needed.

Modular Design and Upgrade Path

Furthermore, the modular design and upgrade path allow the machine to evolve with your ambitions, rather than becoming a limitation to your projects. This approach makes the investment long-term, as capabilities and functions can be adjusted according to project requirements without the need for a complete machine replacement.

KUJIETOOL: A Step Forward in Precision Machining

The KUJIETOOL represents a thoughtful evolution in precision machining, designed specifically for creators who understand that choosing the right tools can unlock new avenues of creativity.

Professional Capabilities Without Complexity

The device offers professional-grade operational capabilities while being designed for smooth, effortless use, even for beginners. This balance between power and ease allows access to creative territories that were previously difficult or impossible for most makers and designers, while naturally supporting the gradual growth of projects.

✦ ArchUp Editorial Insight

From a practical standpoint, the KUJIETOOL offers notable advantages in architectural applications, particularly when precise prototypes or miniature components for experimental designs are required. Its high precision and compact size facilitate the rapid production of small architectural elements, allowing architects to test ideas and concepts before moving on to full-scale implementation.

However, there are several aspects to consider. First, despite the machine’s accuracy, the work area is limited by its compact size, which may restrict the scale of architectural models or the materials that can be used. Second, relying on such devices for larger architectural projects may require integration with other tools or additional manufacturing stages, reducing practical flexibility and adding steps to the workflow. Third, users may face challenges in material stability or in maintaining full control when working with complex architectural elements or larger sizes.

In summary, the KUJIETOOL provides opportunities to enhance innovative thinking and experimental design, but it is not a replacement for industrial processes or traditional workshops in producing larger models. Architects can effectively leverage it during the prototyping and field-testing phase, but its use should be part of an integrated set of tools and processes to ensure compliance with design and engineering standards.

قُدم لكم بكل حب وإخلاص من فريق ArchUp

لا تفوّت فرصة استكشاف المزيد من أخبار معمارية في مجالات الفعاليات المعمارية، و التصميم، عبر موقع ArchUp.