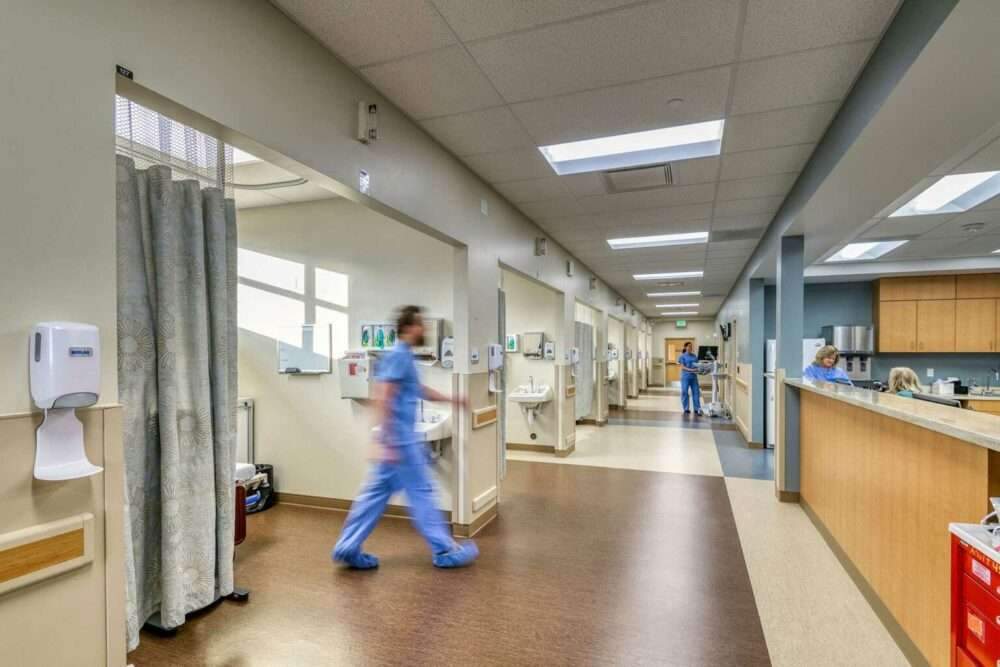

Interior design and sanitary materials in hospitals and health centers,

Interior design in the healthcare world can be complex, as there is a lot to consider

When it comes to ensuring the best possible environment, from a staff and practitioner perspective as well as from a patient perspective.

A knowledgeable interior design team is critical in helping healthcare clients understand design options and choose the materials that will work best for their facilities.

How to determine which materials are best for the job

First and foremost, we must fully understand the activities that will take place in each setting, the types of practitioners and their workflows, related equipment, and maintenance protocols.

And perhaps most importantly, how patients will experience the different spaces.

To ensure project success, it is important to include interior design expertise early in the design process.

The interior designer, along with the rest of the project team, will meet with the client, tour their facilities, and

And the research necessary to truly understand the needs and goals of the project begins.

Defining client goals early on can allow the design team to stay focused and deliver the best solutions.

In addition, we are always learning from our own project teams and previous projects through tools such as Post Occupancy Evaluations,

Plus industry research from institutions such as the Center for Healthy Design.

Finally, we engage in real-world testing, whenever possible, creating mockups for the client’s staff to use and see how the products perform.

For example, we took walkways behind the house and mocked up the floors and walls to test how things held up,

This practical test gives us another round of ideas that we can apply to our work.

Use of sanitary materials in health care settings

The big challenge in the healthcare spaces is finding products that work well, meet budgets, and provide health benefits to people and the environment.

We must take into account the life of materials in each environment with the aim of not having to replace materials as soon or as often.

In addition to considerations such as outgassing and the manufacturing process.

Reducing the number of times flooring material needs to be replaced is essential to reducing construction waste and keeping hospital operations running.

The good news is that we’re seeing a huge shift in the industry with designers (and their clients) insisting on zero-waste products.

Free of volatile organic compounds and polyvinyl chloride (PVC).

As this demand continues to grow, I hope to see more manufacturers innovate in their processes to produce healthy and durable products.

For example, introducing durable PVC-free flooring was a challenge.

But the manufacturers are working out the issues and we’re seeing progress.

And if it happens with paint (non-VOC paint is now the norm), F.C

It can happen with other products and materials.

Meanwhile, we need to continue to be advocates and research the life cycle of each product,

So that we can help our customers make the best decisions for their facilities, employees and patients.

What are the most influential raw materials to select for a project?

In order of importance from an interior design perspective, they are:

Floors, walls (wall protection and paint), ceiling tiles, and furniture.

The encouraging thing about this list is that wall finishes and ceiling tiles are now easy to spot.

In terms of finding what will work well (at all budget levels) and that’s positive in terms of human and environmental impacts.

With the flooring and furnishings, progress has been made, however, these finishes are the most worn throughout any healthcare facility.

Manufacturers are still trying to figure out how to make this material sustainable and durable.

For example, Type 6,6 nylon carpeting has been the gold standard for durability and stain resistance for decades.

And manufacturers are getting ahead and realizing that performance still needs to be there, too.

On the carpet front, many companies are going back to the drawing board to find a sustainable alternative to Type 6,6 nylon with the same performance specs.

This is the case with many materials used in healthcare settings, and carpeting is just one example.

But, there are all kinds of opportunities for innovation, and we’re excited about what we’ll see from the manufacturing industry.

للمزيد من المعلومات المعمارية

https://archup.net/the-use-of-modern-technologies-in-interior-design/