Living Mycelium in Sustainable Construction Materials: A Fungal Revolution

As environmental challenges grow, the construction industry is moving toward more eco-friendly materials. Among the most exciting innovations is mycelium — the root-like network of fungi — which is changing how sustainable buildings are designed using mycelium in construction materials.

But what exactly is mycelium? How is it used in construction? And can it really replace materials like concrete or steel with mycelium in construction?

What Is Mycelium? A Natural Living Network

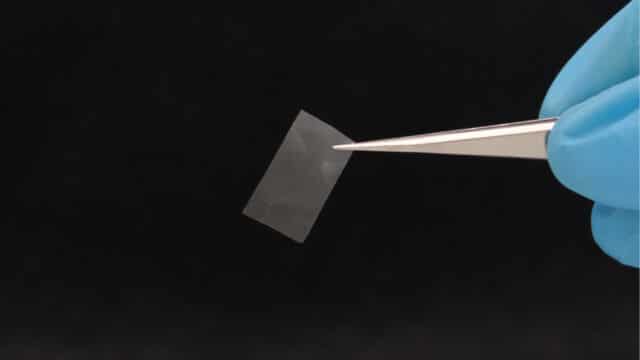

Mycelium is the underground thread-like structure of fungi. It connects plants and helps transfer nutrients in the soil. When grown in controlled settings using waste like straw or sawdust, mycelium can be shaped and dried into solid forms. These forms can then be used in construction materials.

Importantly, mycelium grows naturally rather than being made in a factory. This means it can help reduce carbon emissions during construction when using mycelium in construction materials.

How Is Mycelium Used in Construction?

1. Bio-Bricks and Panels

Mycelium is grown inside molds to create light, fire-resistant bricks with good insulation. After growing, the bricks are dried to stop further growth and harden the material. The use of mycelium in construction materials is proving beneficial here.

2. Natural Insulation

Because of its excellent thermal and sound insulation, mycelium is often used as a natural alternative to fibreglass or foam panels in construction materials.

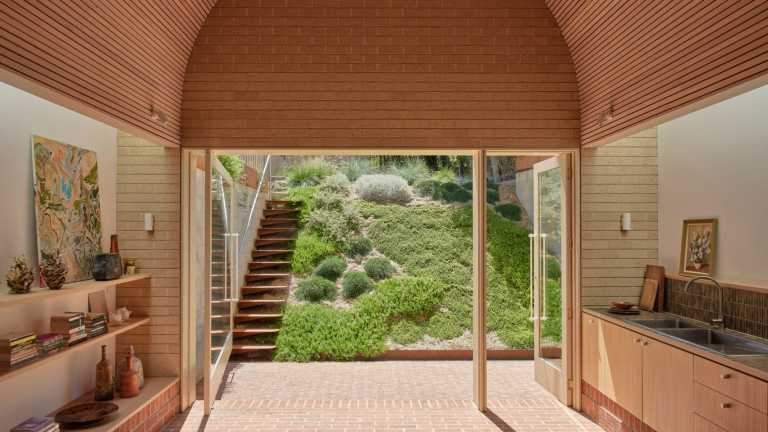

3. Interior Design Elements

Designers use mycelium to create furniture, wall panels, and art pieces that bring a natural and biodegradable touch to interiors.

Main Benefits of Mycelium-Based Materials

Many advantages have made mycelium in construction materials popular in green building projects:

| Benefit | Details |

|---|---|

| Sustainability | Grown from agricultural waste without harmful chemicals. |

| Biodegradability | Breaks down naturally after use, reducing landfill waste. |

| Lightweight | Easy to transport and reduces the weight buildings need to support. |

| Fire Resistance | Naturally resists fire without extra treatments. |

| Thermal Insulation | Helps keep buildings warm in winter and cool in summer, saving energy. |

Furthermore, mycelium materials support certifications like LEED and WELL for green buildings.

Challenges to Wider Use

Although mycelium shows promise, some challenges remain:

- Building codes in many places still do not recognise it.

- Its strength is lower than traditional materials, limiting load-bearing use.

- It requires careful drying and storage to last long.

- Producing large amounts at industrial scale is still being developed.

Ongoing research and new manufacturing methods aim to solve these problems.

Examples of Projects Using Mycelium

Several projects have successfully used mycelium:

- The Growing Pavilion (Netherlands)

Built for Dutch Design Week 2019, this pavilion used mostly mycelium and wood to showcase circular construction. - MycoTree (South Korea)

This structure demonstrated how mycelium can be shaped into strong, self-supporting forms. - Hy-Fi (New York, MoMA PS1)

One of the first large pavilions made from compostable mycelium bricks.

Is Mycelium the Future of Construction?

Mycelium is more than a new material; it represents a new way of thinking about building. If its performance improves and codes accept it, buildings might one day be grown rather than built, leading to greener cities with mycelium in construction materials.

Conclusion

In summary, mycelium offers a fresh, sustainable approach to construction. As the building industry looks for low-carbon solutions, mycelium stands out as a promising material with great potential.

ArchUp is your platform to follow everything “architectural“: news, analyses, and designs from the heart of the modern architectural movement.