Making Data Matter: multi-layered 3D printing to produce data sculptures

Making Data Matter presents a revolutionary method that expands opportunities for presenting data in tangible form by building on existing additive manufacturing technology.

Up until now, 3D data sets are on displays or printed using two-dimensional techniques. Making Data Matter has an aim on improving methods for converting these existing data sets into visual forms rather than on conceptualizing and building new forms.

Why Make Data Important? the physicalization of scientific data sets typically connected with scientific imaging, using 3D printing technology.

This procedure enables the presentation of biological data, such as MRIs, with geospatial data gathered using photogrammetry techniques in ways that provide the viewer with more insightful information. Data physicalization or physical visualization are terms that describe the manifestation of data into such physical forms.

Making Data Matter: Deskriptiv and the Mediated Matter research group

Making Data Matter draws its methods from the MIT Media Lab’s Mediated Matter research group. It is a forward-thinking and creative team focusing on digital fabrication, computational design, materials science, and synthetic biology. The goal of the research is to develop unique technologies inspired by biological and natural processes and used in a variety of industries, including product design, architecture, and fashion.

Since 2010, Christoph Bader and Dominik Kolb, two of Making Data Matter’s principal investigators, have collaborated as descriptive. At MIT, both graduated in 2017 with an M.Sc. in Media Arts and Sciences. Their research focuses on generative processes, in particular ones that result in forms. Bader is now a Ph.D. candidate at MIT.

The project’s originator and director, Associate Professor Neri Oxmandl, and several other researchers are acknowledged for their contributions. Oxman’s work in generative design is famous and has many accolades.

An unusual Rottlace series of masks for Icelandic singer Björk is among the research team’s earlier accomplishments. The masks, which explored the concept of “a face without skin,” drew largely on the musculoskeletal system’s ability to muffle human vocalizations. Wanderers and Vespers are two further exhibits of projects with inspiration by biology.

Materials & Methods – Photopolymer-based multi-material 3D printing

Making Data Matter makes use of the capabilities of multi-material 3D printing, which we frequently use in the creation of complex-geometry prototypes and finished goods. Stratasys is one business that manufactures these 3D printers, and their equipment construct numerous models for this project.

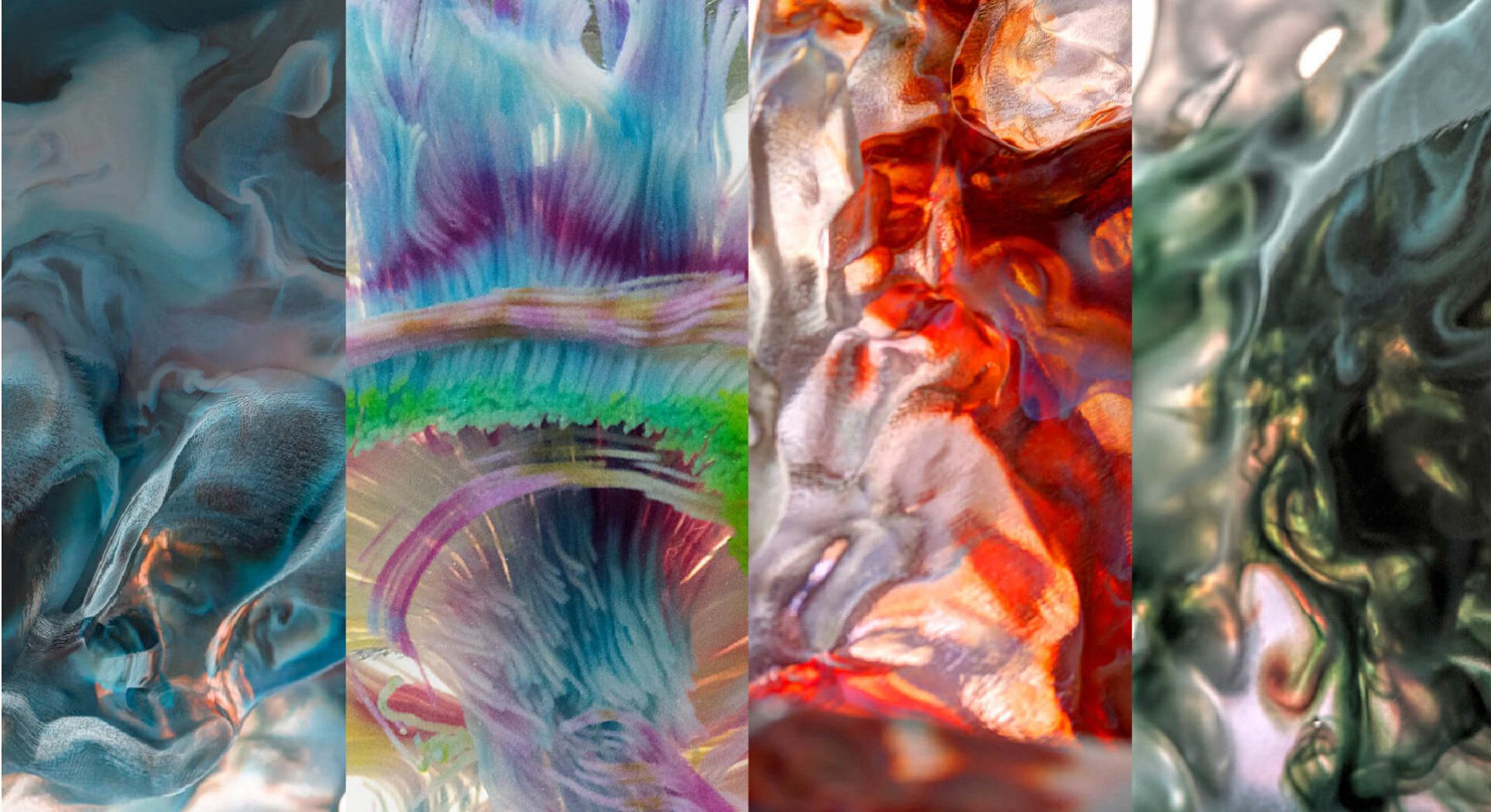

Furthermore, photopolymers, or resins that react to light, create the models. A UV laser is used to build and cure each layer of the thin resin layers that make each model. Using numerous resin colors in a way reminiscent of conventional 2D printing, vivid full-color models are created. To make highly detailed and nuanced artworks with diverse transparencies, cyan, magenta, yellow, black, white, and transparent resins mixed in different ratios.

This represents a considerable improvement over earlier visualization techniques, such as crystal laser engraving or powder-based 3D printing procedures, due to the detail, transparency, and sophisticated use of color. Additionally, its physicality sets it apart from the immersive experiences produced by virtual reality and augmented reality technologies.

Complex suspended data sculptures are an example of the style.

Beautiful plastic resin models are the ultimate product, displaying “opaque data” suspended within a transparent block. Some are rectangular with straight sides, like a small portion of data separated from a larger entity. Others assume a form emblematic of the data container they originated from, like a hand or a human brain. Can we utilize data to represent a brand visually? That is what the experience design firm HUSH designed for the United Therapeutics corporate office.

The main draw of the procedure is the opportunity to view and interact with a physical visualization. As our visual-spatial talents begin to take over, we can understand information more instinctively.

Voxels specify high-resolution 3D printing.

The 3D equivalent of a pixel is a voxel. The more voxels, the better quality model you can print, just as more pixels in a 2D image provide a more detailed image. The researchers highlight that currently, available multi-material 3D printers feature “929 billion individually programmable material droplet places, or voxels,” which we may use to print several materials.

The printer can define and lay down a specific mixture of materials and colors at each voxel. We can use the technique for data visualization; although its main task is to create intricate, high-resolution representations of things like anatomy.

Rethink the workflow using Design Memento

Making Data Matter rejects the conventional 3D printing process, which is characterized by discrete materiality and polygon surfaces. Instead, it develops a way to communicate directly with the multi-material machines’ printing capabilities.

Moreover, it removes the need to post-process data by using voxels and sending data in the printer’s original resolution. According to the researchers, “we demonstrate that data sets typically seen on screen can be turned into real, materially heterogeneous things by transforming data sets into dithered material deposition descriptions, through improvements to rasterization procedures.”

Finally, the technique is excellent for visualizing sets of discontinuous data. That is, we must understand point clouds and data in terms of their spatial interactions with one another rather than sitting together neatly as a “single item.”

Read more on Archup:

استدامة جميلة على منصة جوائز التصميم الألمانية | الأخبار | Architonic

An Arquitectonica-designed supertall office tower is coming to Miami