The Swiss Brick Museum Project: Revisiting Traditional Rammed Earth Construction Techniques

Manual Brick Factory in Switzerland

The brick factory, known today as the Brick Museum, is the only remaining fully manual brick-making factory in the German-speaking part of Switzerland. This complex serves as a living example of traditional construction techniques and artisanal craftsmanship from a previous era.

Complex Components

The factory consists of several interconnected buildings serving different functions, including:

- Wooden Warehouse: Dedicated to drying bricks after production.

- Historic Kiln: Despite its historical value, it may no longer be operational.

- Natural Habitat: Surrounds the clay quarry, reflecting the integration of industrial activity with the natural environment.

- Residential Buildings and Gardens: Historically linked to the workers and contributed to sustaining the life of the industrial community.

- Museum Building: Replaced the burned barn and contains exhibits documenting the history of brick-making and related techniques.

Educational and Design Experiment

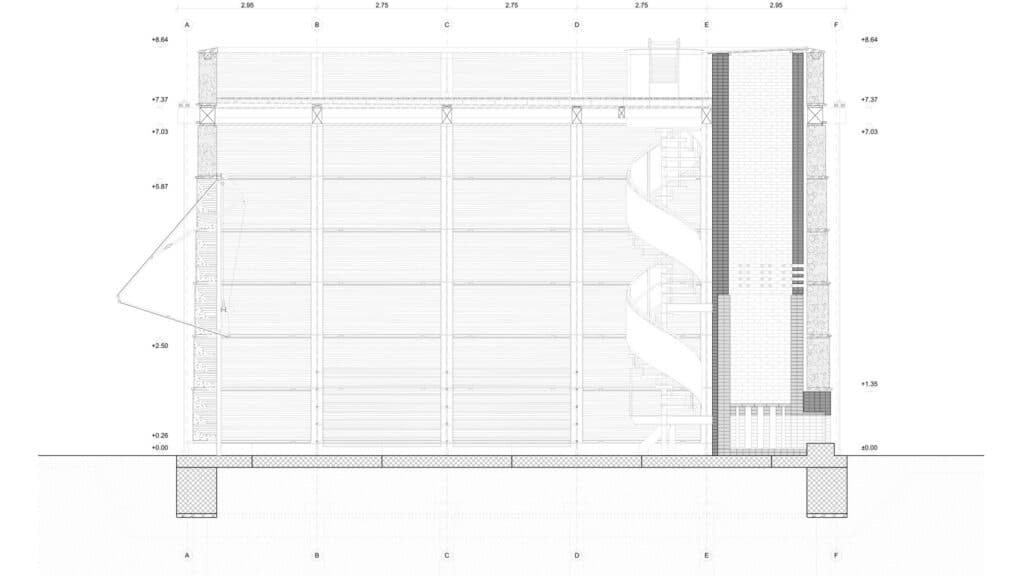

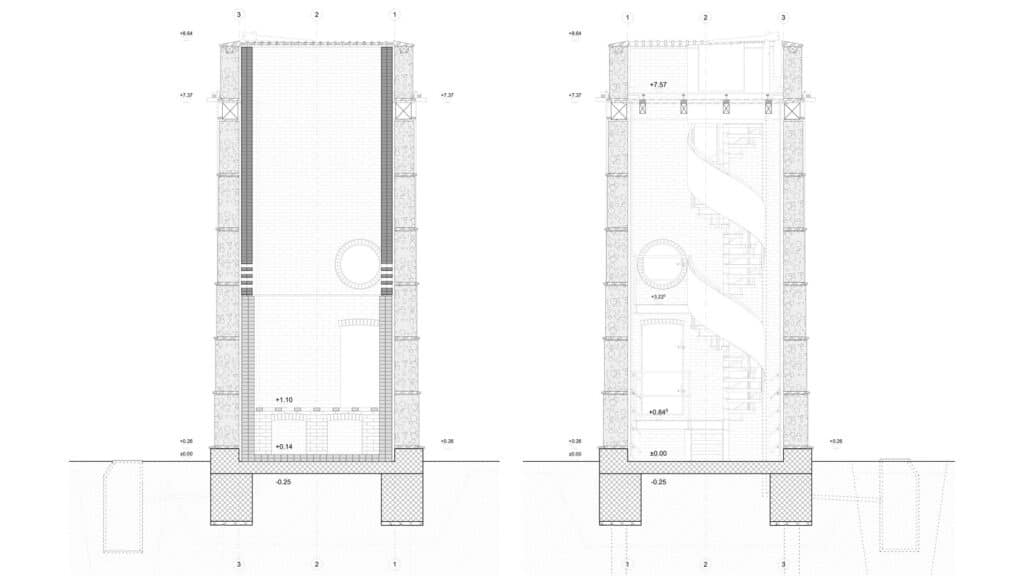

In 2017, visiting graduate students from Munich Technical University undertook the task of designing a new kiln tower on site. The design was based on the experimental model at Sitterwerk, and this tower represents the world’s first pre-stressed earthen building. The structure relies on pre-stressed earthen and wooden techniques, connecting engineering innovation with the preservation of the site’s historical character.

Site Significance

This complex provides a unique opportunity to study traditional brick-making techniques while offering a model for interaction between modern engineering and industrial heritage preservation. Furthermore, it highlights the relationship between architectural design and educational practices, allowing both professionals and students to test innovative solutions within an authentic historical context.

Traditional Building Materials Display

The complex showcases clay in its natural, unfired state, allowing visitors to understand the initial stages of brick-making. It also highlights the contemporary evolution of the traditional rammed earth construction method, linking conventional building techniques with modern innovations.

New Observation Tower

The new tower offers visitors the opportunity to view the site from an observation platform approximately eight meters high. This experience provides a comprehensive perspective of the complex and helps in understanding the architecture associated with manual brick-making.

Practical Use and Future Expansion

In addition, the tower allows the staff to re-fire bricks using the new kiln, ensuring the continuity of the traditional production process. A space will also be created to display other museum collections, enhancing the educational and cultural value of the complex and adding an interactive dimension for visitors.

Exhibition Room Adjacent to the Kiln

The exhibition room next to the kiln features a solid wooden ceiling that contributes to the structural stability of the building. The overall character of the room is defined by the presence of clay and the large final kiln wall, giving visitors a tangible sense of the original materials and traditional construction techniques.

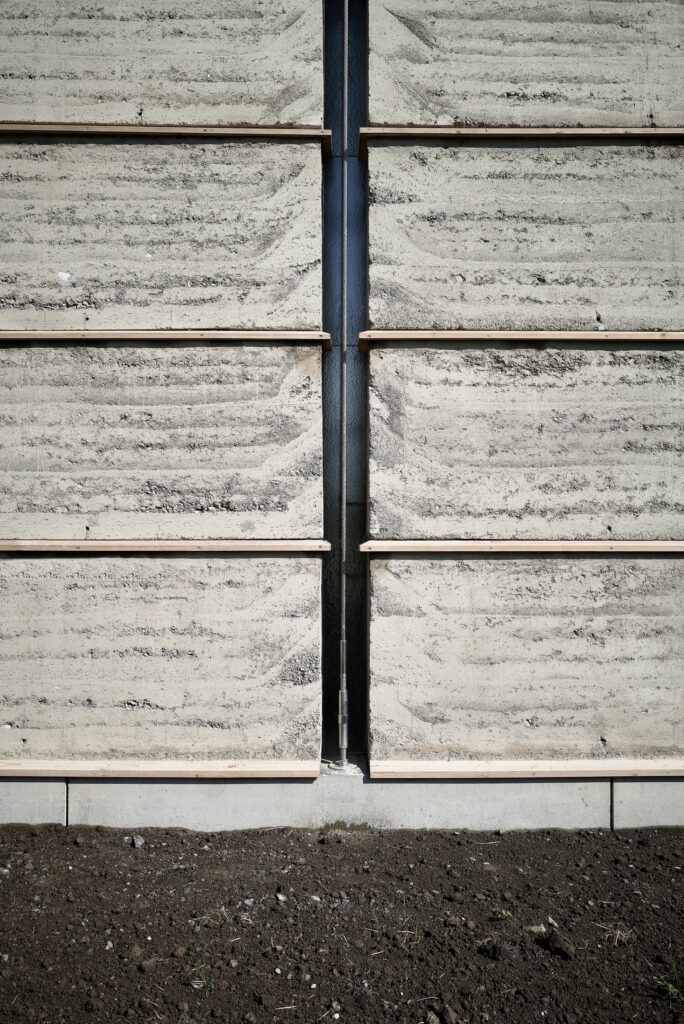

Experience of Solidity and Construction

The light gaps in the open joints, which pass in front of the prestressed elements, allow visitors to experience the full solidity of the rammed earth walls. This contrast between the wall robustness and the precision of the tension rods illustrates the meticulous engineering employed in both traditional and contemporary construction.

Display Infrastructure

Simple steel structures can be mounted on the walls to support display panels or exhibits, adding a practical dimension to the exhibition room. A spiral steel staircase provides access to the rooftop observation platform, giving visitors a broader perspective of the complex and enhancing their interaction with the architectural elements.

Rammed Earth Construction: Tradition and Innovation

Although construction using rammed earth elements is not new, the joints between blocks, whose size depends on transportation and installation conditions, are often filled manually, a process that is time-consuming. This limits the practical benefits of using prefabricated elements and highlights the significance of this experimental architectural project, which aims to enhance construction efficiency and stability through innovative solutions.

Structural Innovation One: Prestressing

The first innovation is prestressing, which provides the system with the ability to resist seismic loads. In this context, the earth bears only compressive forces, while the tensioned steel provides integrated support, creating an optimal balance between structural robustness and precision.

Structural Innovation Two: Integration of Wooden Elements

The second innovation lies in integrating the wooden element bases into the wall structure. Weather protection edges are installed on these bases directly on-site to protect the earth from erosion, while simultaneously clarifying the principle of interconnection between the different elements, enhancing the building’s stability and prolonging its lifespan.

Scientific Monitoring and Rammed Earth Research

The scientific monitoring of the project represents a significant contribution to the development of rammed earth research, providing practical data on sustainable construction techniques and their structural efficiency.

Utilization of Natural Resources

In Switzerland, more than sixty million tons of earth and clay are extracted annually, most of which is currently used to backfill gravel quarries. This underutilized resource offers an opportunity to find new construction methods, contributing to the replacement of conventional, energy-intensive building materials such as concrete and bricks.

Energy Efficiency and Environmental Impact

Compared to traditional construction methods, such approaches can save up to forty percent of embodied energy in new buildings. This highlights the environmental and economic benefits of rammed earth construction projects and underscores the significant potential for reducing the carbon footprint of the urban sector.

✦ ArchUp Editorial Insight

The Swiss Brick Museum project represents a tangible example of integrating traditional construction techniques with elements of structural innovation, such as pre-stressing and the incorporation of wooden components. The complex allows architecture enthusiasts to study rammed earth as a building material and interact with the building’s components practically, which can be seen as a positive aspect that enhances both theoretical and experimental knowledge in the field.

However, the project remains limited in several ways: relying on experimental models for the tower and new facilities may restrict the applicability of these techniques on a larger scale, especially in large residential or commercial projects. Additionally, the focus on manually reproducing bricks and the reliance on meticulous maintenance of the kiln and wooden elements make the project time- and labor-intensive, raising questions about its economic feasibility when applied to broader architectural contexts.

Furthermore, while rammed earth offers the potential to reduce energy consumption compared to conventional concrete and bricks, controlling factors such as moisture, erosion, and climate presents an ongoing challenge, requiring careful scientific monitoring to ensure the building’s long-term sustainability.

Despite these constraints, the project can be considered a valuable resource for practical research and architectural education, as it enables engineers and students to understand the interaction between traditional materials and modern techniques, and to experiment with design solutions that may inform future projects, particularly those aimed at reducing environmental impact and developing sustainable construction methods.

Project information

- Architects: Boltshauser Architekten

- Area: 60 m²

- Year: 2021

- Photographs:Kuster Frey