Signs of improper concrete and their causes

Unsound concrete can be identified by various signs such as visible cracks, micro-cracks,

spalling, flaking, blistering, and delamination.

Multiple factors lead to different types of damage, and as a result,

a specific repair strategy may be required for each type of concrete damage.

The most important signs of improper concrete

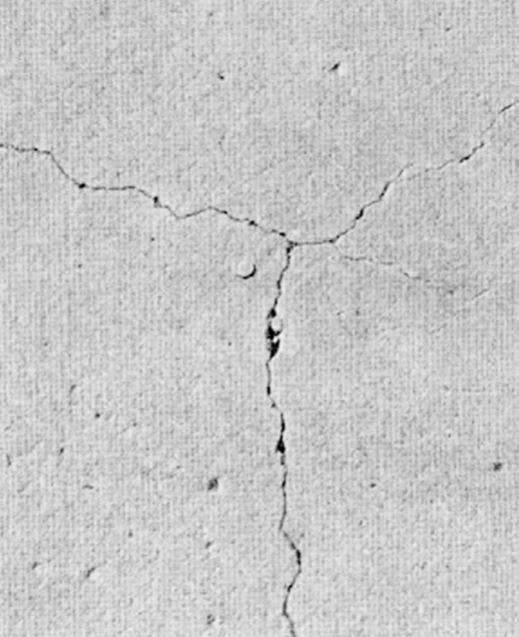

1. Visible cracks

Visible cracks are the most obvious symptom of improper concrete and have several causes.

For example, heavy impact or loads can cause cracks that are immediately visible or cause microcracks that develop into visible cracks.

In addition, surface cracks are caused by the rapid loss of water from the surface of the concrete during the curing process.

Moreover, settling of the subgrade leads to the development of cracks in the concrete slabs.

Finally, shortening of concrete elements is another factor that exacerbates crack propagation.

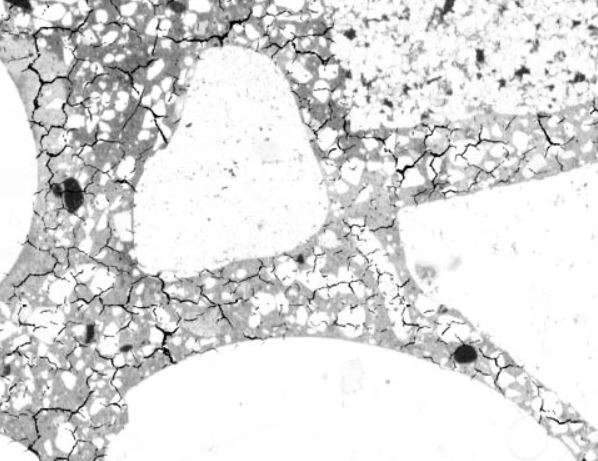

2. Fine cracks

Micro cracks are invisible to the naked eye and are measured on the micron scale.

Possible causes of microcracks in concrete structures are overloading,

freezing and thawing, temperature variations during cement hydration,

and impacts from falling loads and impact tools such as scrap tools.

Concrete bruising occurs when microcracks create a network near the surface.

Then, the concrete may crumble away, exposing the aggregate.

3. blisters

Blisters appear when air or water bubbles trapped through plastic concrete under an already airtight surface bubble up.

Contributing factors to the formation of blisters are a very viscous concrete mixture that seals the surface quickly,

undertaking finishing work when the concrete is still spongy,

and insufficient vibration during compaction that fails to release trapped air.

4. Unloading

The hollow is a hollow horizontal plane below the surface of the concrete.

They form when finishing begins before water and air can escape the concrete.

Other causes of segregation are the cold substrate which extends the bleeding time of the concrete,

and the high ambient temperature which speeds up the concrete setting process.

Due to heavy loads, loose concrete may separate from the concrete slab and, as a result, aggregates are exposed.

5. Sizing

Scaling is the loss of concrete near the surface due to freezing and thawing.

When the water in the concrete pores solidifies and the hydraulic pressure of the expanding ice exceeds the tensile strength of the concrete,

the mortar scales off the surface, exposing the aggregate.

The causes of scaling are exposure of concrete to repeated freeze-thaw cycles,

use of de-icing devices, and a high water-to-cement ratio.

6. Fragmentation

Chipping is similar to sizing, but the depth of concrete separation from the concrete surface is greater.

The causes of spalling are corrosion of reinforcement,

violent evaporation of moisture in concrete due to extreme heat, improperly constructed joints, and crack deterioration.

How to determine the extent of improper concrete

The above signs may indicate significant damage, but the full extent of the damage is not always clear.

For this reason specific simple testing techniques may be required.

- Tap the periphery of concrete area that is obviously weak with a hammer. If the hammer head bounces, the compressive strength of the concrete is good.

However, if the hammer head crushes the surface of the concrete, the concrete is unsound and weak.

- Listening to the sound produced by the hammer can reveal areas of different intensities.

This technique can be useful in identifying pockets of air, water or unwanted materials that form below the surface of the concrete.

- Apply or drag a screwdriver across the concrete surface.

If the energy scratches, the concrete is not intact, however, if it creates a bright white line, the concrete is intact.

For more architectural news