Your complete guide to learning about LEXAN panels,

LEXAN is a polycarbonate thermoplastic, in short, what that means is that it is a rigid material that can deform in extreme heat

(usually 147 degrees Celsius, or 297 degrees Fahrenheit).

Its molecules are composed of repeating subunits,

and Lexan is just one of a family of thermoplastics whose main reason for their popularity is their ability to undergo significant deformation without fracture.

What’s more, when fully formed, polycarbonate sheets boast impact strength 250 times greater than that of glass

and 30 times greater than that of acrylic (a similar thermoplastic).

This strength and flexibility have made Lexan sheet an indispensable material for a wide range of manufacturers,

as very few materials can claim Lexan’s transferability along with its outstanding heat and impact resistance.

Lexan benefits and uses

The great features of polycarbonate include:

- High impact resistance (250 times the impact resistance of glass)

- Low stiffness and can be purchased in flexible grades

- Can handle temperatures up to 240 degrees Fahrenheit before deformation

- Highly resistant to acids and other chemicals such as benzene

- It can be drilled without worrying about cracking

- It can be cold formed or bent without heating

- Low level of flammability

However, this does not mean that Lexan is a perfect material.

There are some trade-offs that manufacturers are forced to accept for this level of flexibility and overall strength.

Trade-offs includes:

- • Easier to scratch than glass and some other thermoplastics

- More expensive than glass and some other thermoplastics

- Poor clarity, it cannot be polished to restore clarity

- It can turn yellow over time due to ultraviolet rays

- Low level of resistance to abrasive surfaces and detergents

- Can be dented easily

Overall, these attributes make LEXAN polycarbonate an excellent material

for applications where you are concerned less with aesthetics than with creating a highly resistant protective surface.

This is why it is now found in products such as those listed above and as a key ingredient in the following.

- A well covered window

- Automotive windshields and windshields

- Reusable drinking bottles

- Computer and phone cases

- Transparent visors for football and hockey helmets

- Urethane and silicone casting molds

- Machine guards

- LED light tubes and diffusers

- Bulletproof glass

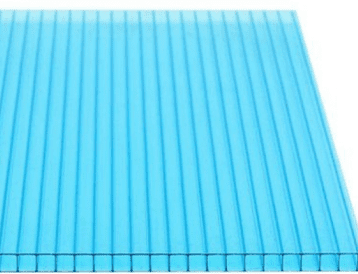

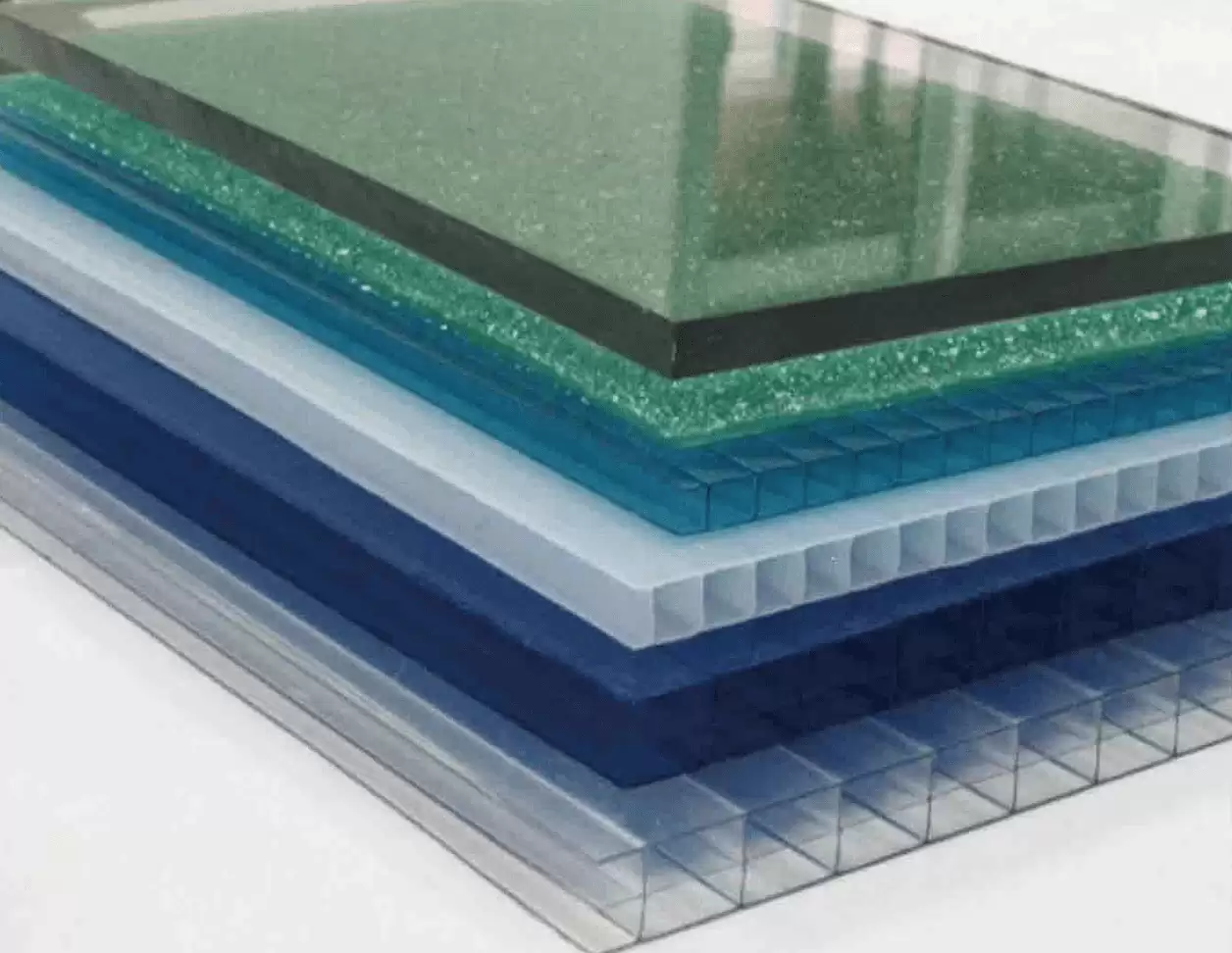

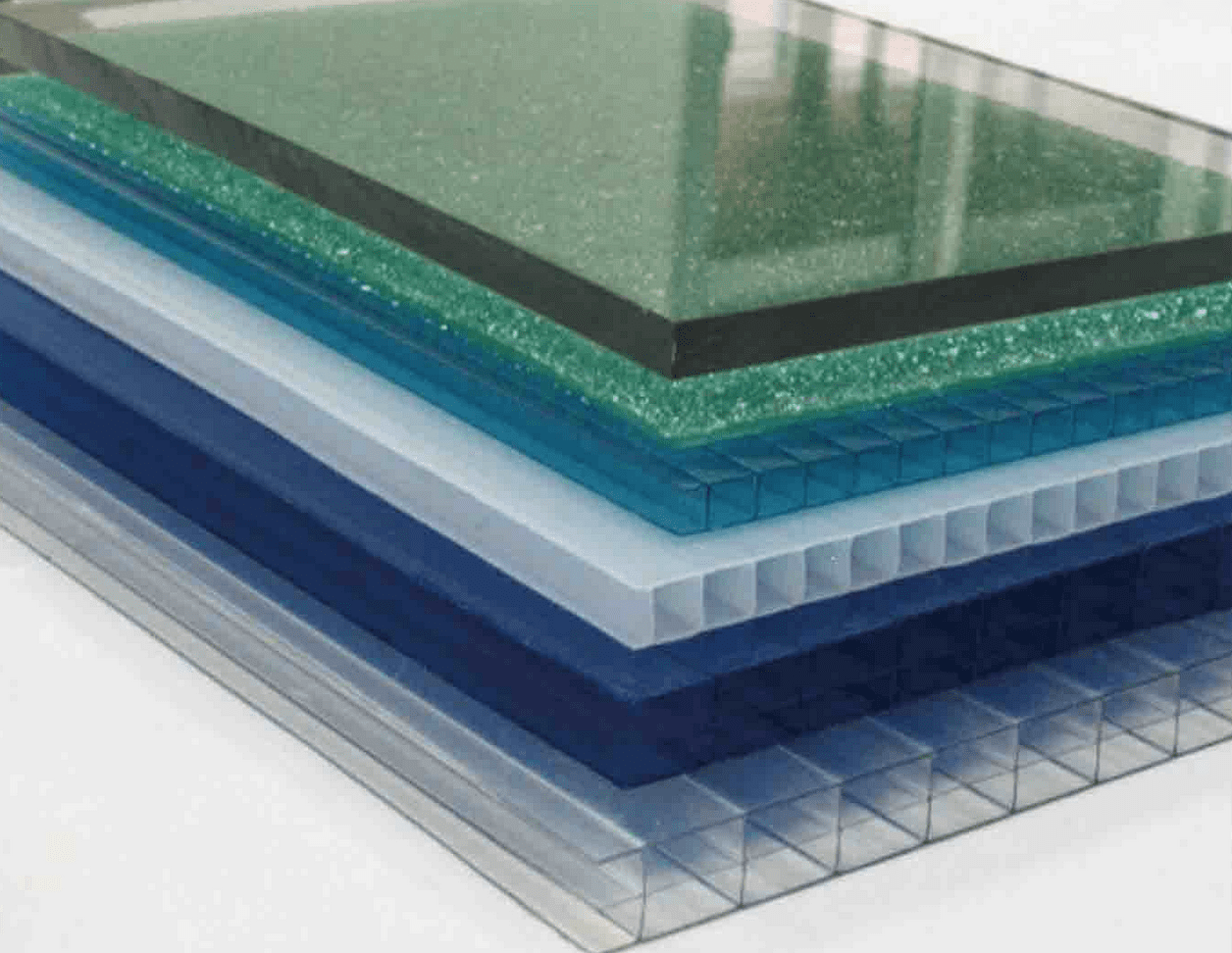

Sizes of polycarbonate sheets (hollow)

Thickness: from 4 mm to 10 mm

Sizes: width 2.1 m / length 5.8 mm or 11.8 mm (any required length can be made)

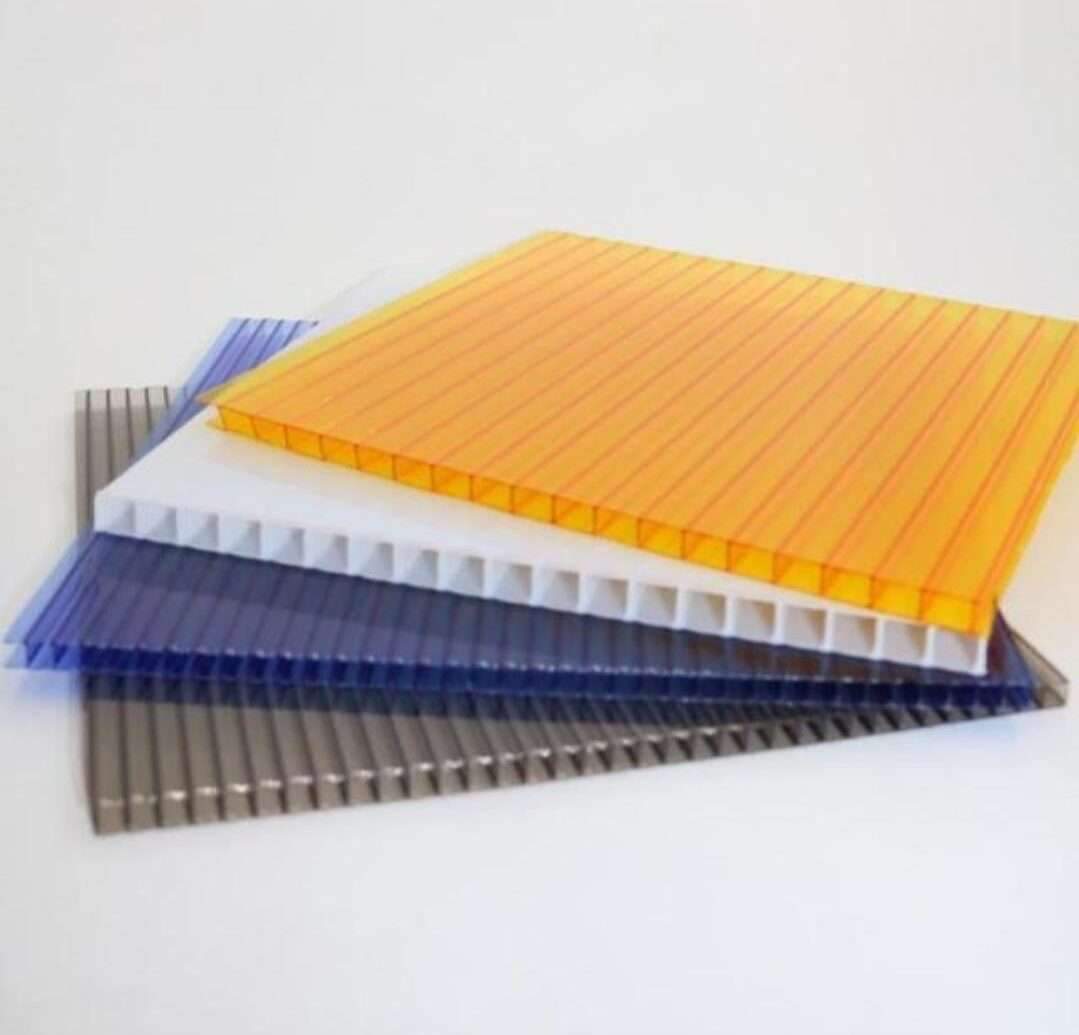

Colors: transparent, bronze, blue, lake blue, green, green, white, gray, silver, red, yellow, purple, orange, black, etc.

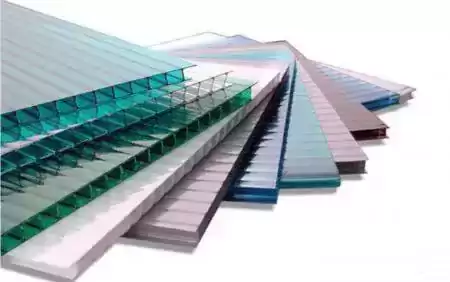

Polycarbonate panels (solid and crystal)

Thickness: from 1.3 mm to 10 mm

Sizes: width 2.1 m / length 5.8 mm or 11.8 mm (any required length can be made)

- Hollow panels, thickness 4.5 – size 2.1 x 5.80.

- 5.5 mm thickness hollow plates – size 2.1 x 5.80, colors (transparent – blue – brown – green – orange – milky).

There are also many sizes available in the market, as follows

- The first type, German vacuum panels, thickness of 6 mm – size 2.8 x 5.80, colors (transparent – blue – brown – milky).

- Hollow panels, first graded, thickness 6 mm – size 2.10 x 5.80.

- The best first class hollow sheets, thickness 10 mm – size 2.10 x 5.80.

- Also available in size 280 cm x 130 cm with a thickness of 3 mm.

- Finally, a size of 300 cm x 200 cm with a thickness of 2 mm.

For more architectural news