AtomForm Palette 300: A Practical Approach to Multi-Material, Multi-Color 3D Printing

The Gap Between Theory and Practice

Desktop 3D printing has long been promised to deliver “anything you can imagine,” yet in reality, it is often limited to single-color PLA prints and numerous manual experiments, resulting in significant waste and repeated reprints. In practice, the colorful designs showcased at conferences often differ greatly from what most desktop printers can actually produce, prompting many designers to abandon FFF technology except for simple prototypes.

AtomForm Palette 300: An Attempt to Bridge the Gap

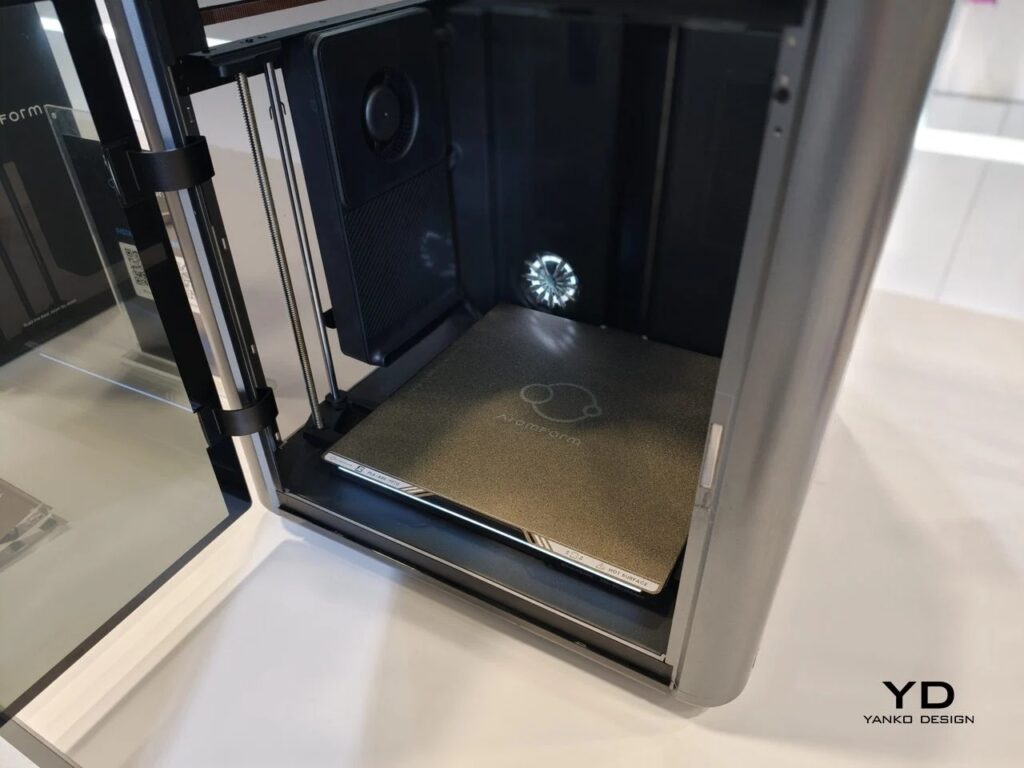

The AtomForm Palette 300 aims to address this gap. It is a closed 3D printer equipped with 12 nozzles, designed to integrate up to 36 colors and 12 materials into a single cohesive print.

OmniElement Technology for Waste Reduction

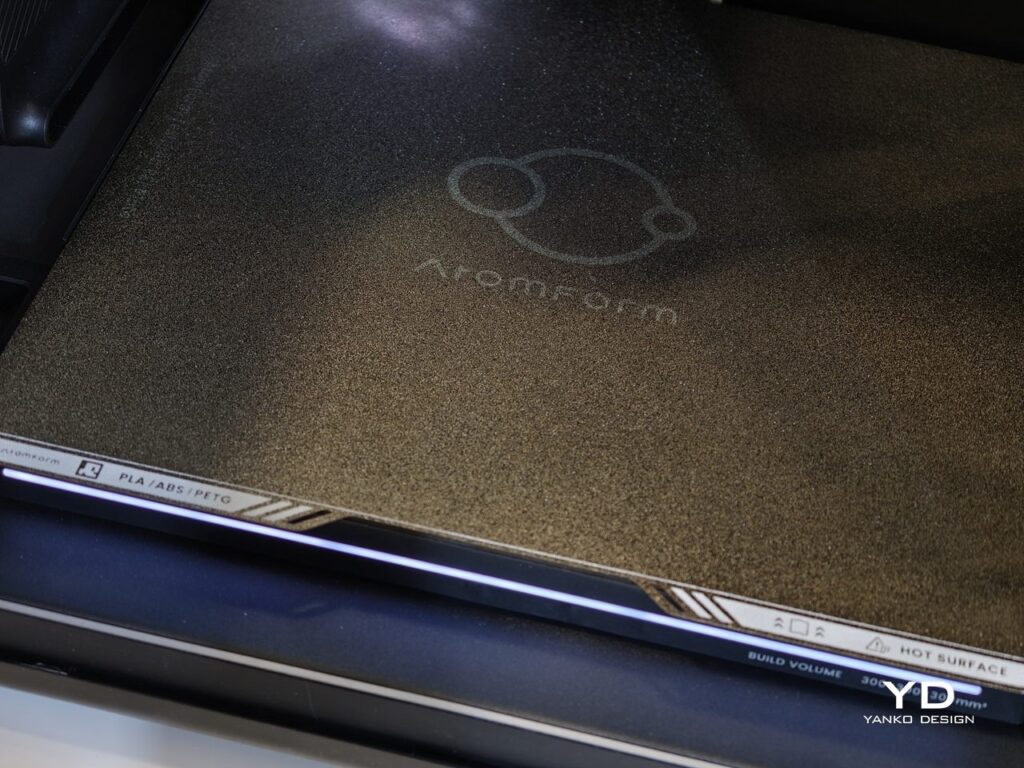

The printer relies on a rotary nozzle system known as OmniElement, where each nozzle is dedicated to a single filament strand. This system reduces waste by up to 90% compared to traditional methods by avoiding constant nozzle cleaning.

Printing Performance

Additionally, the printer supports speeds of up to 800 mm/s, with accelerations reaching 25,000 mm/s², within a closed cube measuring 300 × 300 × 300 mm. These specifications indicate the printer’s capability to handle relatively complex projects compared to conventional desktop printers.

Challenges in Multi-Material Printing

Most multi-material printers face practical limitations: they either replace entire tool heads with each color change or force a single nozzle to undergo continuous cleaning. These processes consume time and filament, making complex printing tasks exhausting and inefficient.

The Solution in the Palette 300 Design

In contrast, the Palette 300 printer tower, equipped with 12 nozzles dedicated to individual filament strands, offers a smoother workflow. It allows switching between nozzles without constant reloading, making complex color and material changes faster and more efficient.

Color Accuracy and Print Detail

As a result, the printed model can feature precise, brand-accurate colors, along with smooth textures for handles or touch-sensitive parts, all within a single integrated print process, without additional waste or extended print times.

Capability to Handle Engineering Filaments and Large Parts

With a 350°C hotend and a 300 mm build volume, the printer enables the use of advanced engineering filaments and the printing of parts much larger than simple decorative models.

Material Integration in a Single Model

This integration allows, for example, printing a prototype of a sports shoe combining flexible soles with rigid eyelet components, or an architectural model featuring transparent windows and textured facades, all in a single print. This eliminates the need for multiple prints that must later be glued together, saving time and reducing potential errors.

Impact of Integration on Productivity and Accuracy

This level of integration increases the number of possible iterations per day and enhances confidence in the practical fit of parts, making the model development process more efficient and realistic compared to traditional multi-step printing.

The Role of AI and Sensors in Reliability

The reliability of the Palette 300 printer depends on the integration of artificial intelligence with an advanced array of sensors. The printer features over 50 sensors and four AI-powered cameras to monitor the printing process in real time.

Precise Calibration and Defect Detection

These systems automatically calibrate nozzle alignment for all 12 extruders and detect potential defects before they can compromise a long print job.

Impact on User Experience

For complex operations lasting several hours, this technology provides high confidence that the printer will complete the job successfully, eliminating the need for constant supervision, thereby improving efficiency and reducing user stress. This makes it particularly useful for design teams working on intricate models.

Ergonomic Studio-Friendly Design

User comfort in the studio is as important as the printer’s performance. The fully enclosed design allows the printer to operate in diverse environments such as shared offices or classrooms, not just in a dedicated backroom.

Low Noise Levels and Air Purity

With a noise rating of ≤48 dB, the printer operates quietly without disturbing its surroundings, while the built-in air filtration system removes fine particles, maintaining a clean and healthy workspace.

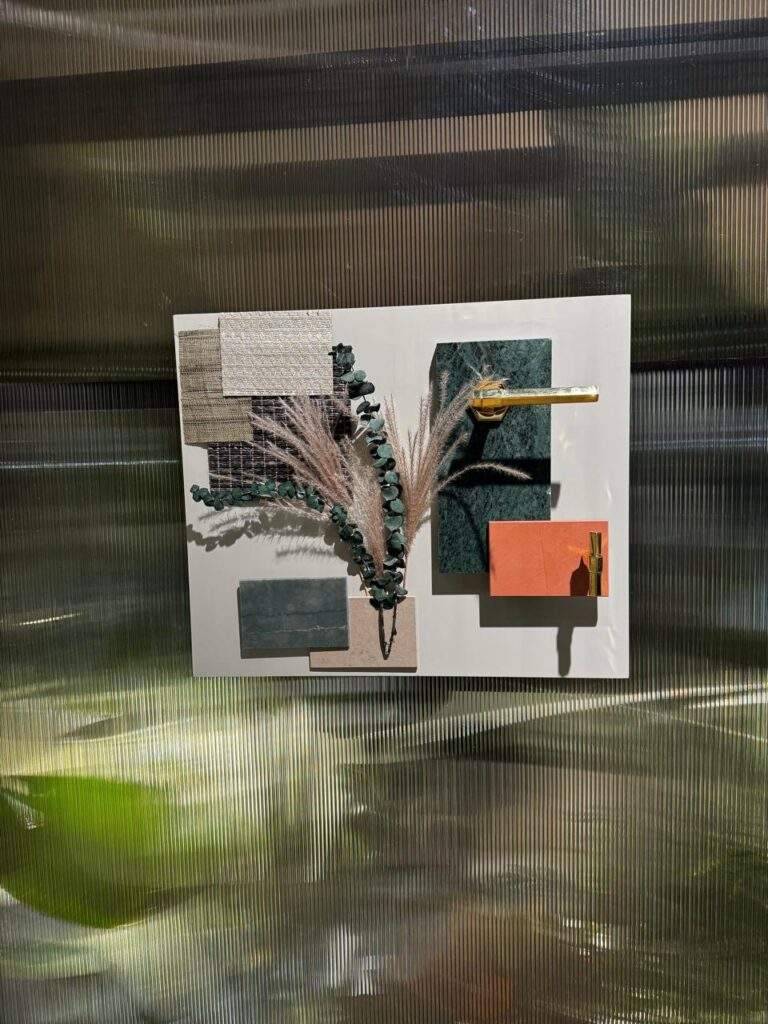

Flexible Filament Management and Ready-Made Color Library

The printer can accommodate up to six RFD-6 filament boxes, keeping 36 spools ready for printing. This provides the user with a full library of colors and materials preloaded and ready to use, instead of storing them temporarily in cardboard boxes, enhancing workflow speed and efficiency. This is particularly beneficial for teams working on building materials research or projects requiring rapid prototyping.

A Step Toward Practical Multi-Color FFF

The AtomForm Palette 300 represents an attempt to move multi-color FFF 3D printing from being a mere exciting novelty to a tool that designers can rely on in practice.

Initial Assessment and Reliability Considerations

As a first-generation machine from a new brand, its long-term reliability and software polish are still under evaluation. This means designers and users should consider that consistent performance has yet to be fully proven.

Combining Innovation and Performance

Nonetheless, the combination of 12-nozzle hardware, AI-assisted oversight, and a carefully planned filament system makes it one of the most interesting 3D printers showcased at CES 2026. This is particularly relevant for those seeking a balance between fine detail, color, material diversity, and printing speed without compromising any aspect.

✦ ArchUp Editorial Insight

The AtomForm Palette 300 can be seen as an interesting tool in terms of its ability to integrate multiple colors and materials into a single model, potentially enabling architectural designers to explore prototypes that are more complex and precise compared to traditional printing. For instance, the ability to print transparent facades alongside solid elements in the same model can help visualize intricate architectural assemblies or study the interaction between different materials before real-world implementation.

However, there remain numerous practical limitations that restrict its full adoption in architecture. Being a first-generation printer from a new brand, its long-term reliability and software polish have yet to be proven, making reliance on it for large or complex projects risky. Additionally, despite the material and color integration, the limited build volume (300 × 300 × 300 mm) is a constraining factor, as the printer cannot produce large models directly without splitting them into multiple parts and assembling them afterward, adding layers of complexity and increasing the likelihood of errors.

The precise operational requirements, AI monitoring, and need for specialized filaments also make the printer more complicated to use for traditional architectural design teams seeking fast and reliable solutions. Moreover, the cost of diverse materials and associated equipment may render the printer less practical for projects that depend on continuous production or large multi-part models.

Overall, the Palette 300 can be considered a limited supportive tool in architecture, most useful during the exploration and fine prototyping stages rather than as a practical replacement for large-scale architectural printing or sizable models. Its optimal use appears to be tied to limited experiments, trial models, and studying material interactions, while keeping in mind the constraints of volume and reliability. For more research and insights, users can refer to the research section or explore relevant archive content on similar projects.