Building using environmentally friendly materials

Buildings in ancient civilizations used weather-resistant building materials that were available in the environment such as stone, clay, wood and thatch.

Among the most famous and oldest building materials used are clay and burnt bricks.

There must be two basic conditions for building materials to be environmentally friendly, and they are:

- It should not be one of the materials that consume high energy, whether in the manufacturing, installation or even maintenance stage.

- Not to contribute to an increase in internal pollution in the building.

It is also necessary to exclude materials and finishes that have been proven to have a harmful effect on health or the environment, and attention should be paid to trying to search for alternatives.

ويجب أيضًا إستبعاد المواد والتشطيبات التي ثبت تأثيرها الضار على الصحة أو البيئة، والإهتمام بمحاولة البحث عن البدائل.

Among the harmful materials and finishes:

- P.V.C and formaldehyde, which is used as an adhesive.

- Vinyl material, which is used in floors and plasticizers that make furniture and doors, as it emits some gases that are harmful to health.

Therefore, many experts recommend the importance of using natural materials and paints,

which are based on natural oils.

Such as linseed or cottonseed oil, with the exclusion of modern chemical paints that emit volatile organic compounds that are harmful to health.

Recycled plastic

Instead of sourcing new components for construction, mining and milling,

manufacturers have used recycled plastic and other earth waste to produce concrete.

This practice reduces greenhouse gas emissions and gives plastic waste a new use instead of clogging landfills and contributing to plastic pollution.

In the polymeric wood industry, a mixture of recycled plastic and virgin plastic is used.

It is used to make picnic tables, fences, and other structures, and at the same time save trees.

Plastics from 2-liter bottles can be spun into fibres, to produce carpet.

Recycled plastic can also design products, such as cable conduits, ceilings, floors,

PVC vents and PVC windows.

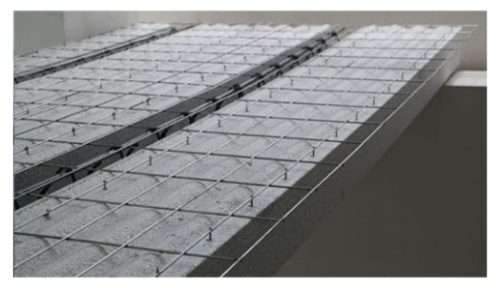

3D panel insulated panel technology

Insulated panel technology: NEDION system

An advanced building system has spread widely throughout the world,

and is designed to use materials that combine structural and physical properties.

It is required to be available in the facilities as an alternative to the traditional used materials.

This Italian system was known as the Nedion system.

It is a system based on the use of panels made of polystyrene foam, which have a density of 15 to 25 kg per cubic meter.

It is sandwiched between two layers of iron with a tensile strength of 60 kg per square millimeter and it forms the structural parts of the building.

Advantages of insulated panel construction

-

The speed

The speed of work using the three-dimensional panels was compared with the normal construction represented by concrete columns.

-

Easy to install

Compared to ordinary construction, insulated panels are easier to install, for the following reasons:

- The ability to benefit from any available workforce, without the need for highly skilled people in multiple fields.

Because the panels are light in weight, there is no need for workers, loading or unloading equipment, or cranes.

- The ease of movement makes it easy to make any changes in the ceiling.

Specifications for 3D insulated panels:

Earthquake resistance

The complete cohesion of the building through the steel mesh that encases it, as well as the uniformly poured cement on the entire structure, makes the building not prone to changing its shape.

This is a great advantage that makes it more earthquake resistant and more effective.

Construction is also completely insulated with heat, cold and sound, without the need to use additional materials.

The cork used is non-flammable in the event of a fire in the building.

The cost

Completely completed buildings using 3D panels are very economical compared to construction for the following reasons: :

- There is no need for large and excessive labor, which saves in the expenses of housing, accommodation, food and the like.

- Simultaneous completion of the construction of external and internal walls, ceilings, stairs and connections, which saves time and money.

- No need for heavy cranes to transport materials inside the construction workshop, which saves large sums of money.

- No need for places to store raw materials in large quantities, such as sand, cement, gravel, bricks, blocks, and so on.

The panels do not need special stores.

- The speed of completion of construction leads to the prevention of changes in the market and prices of raw materials.

- No need for heat, moisture or sound insulating materials, which saves large amounts of money in construction.

For more architectural news

Renovation of Khalifa International Stadium ahead of the 2022 FIFA World Cup