Soil, Water, and Cardboard: A New Formula Redefining Sustainable Construction

A Beginning with an Unexpected Idea

What if the future of sustainable construction relied simply on soil, water, and cardboard?

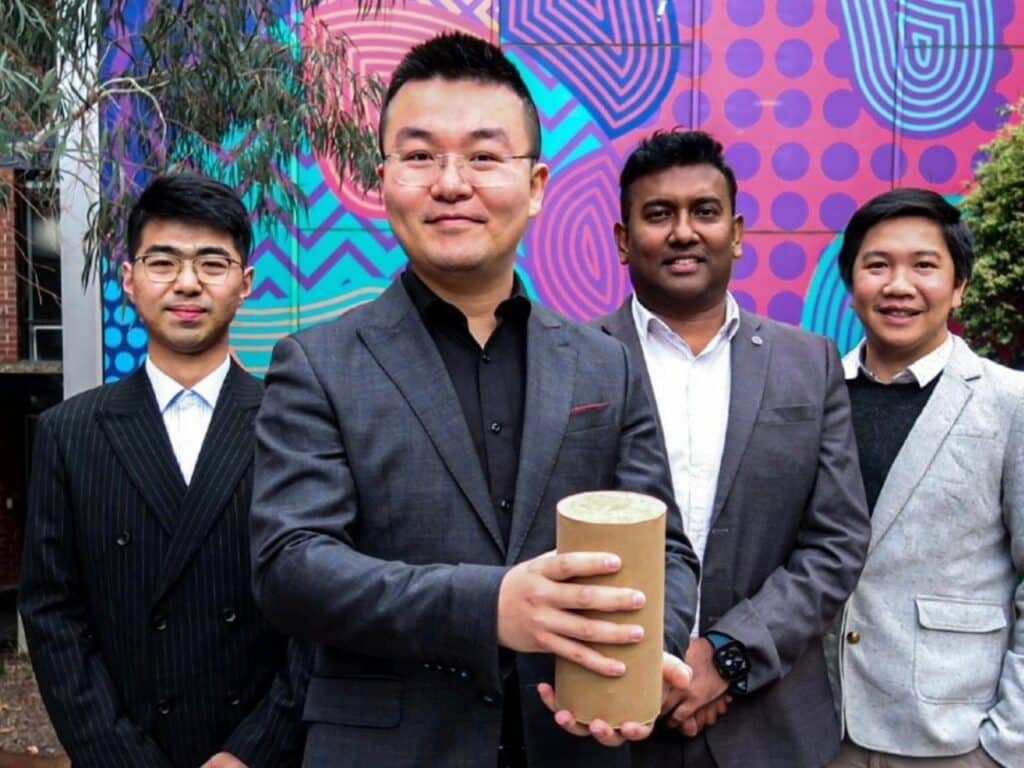

This concept may seem almost too simple to believe, yet a team of researchers at RMIT University in Australia has successfully developed a revolutionary new material combining these three elements, which they named Compacted Clay Reinforced with Cardboard (CCRE).

The Problem with Traditional Concrete

Concrete is widely recognized as one of the most essential materials in modern construction, forming the backbone of most cities and structures.

However, behind this significance lies a huge environmental cost; the cement and concrete industry contributes approximately 8% of global carbon emissions annually.

In other words, the very material that built our modern world is simultaneously putting immense pressure on our planet.

The Other Side of Paper Waste

Meanwhile, countries like Australia face a growing problem of paper and cardboard waste accumulation.

According to statistics, Australia sends more than 2.2 million tons of cardboard and paper to landfills every year, a staggering figure highlighting the urgent need for more effective recycling methods.

From Crisis to Innovation

Based on these insights, the RMIT team viewed concrete pollution and cardboard waste as two interconnected problems that could be addressed simultaneously.

Rather than treating them as environmental burdens, the team decided to transform them into an innovative opportunity to create a new building material that combines sustainability and efficiency at the same time.

Simplicity of Idea, Depth of Innovation

The concept is based on a simple principle, yet it is ingenious at its core.

Instead of relying on traditional molds that are removed after the concrete hardens, the researchers used cardboard tubes as permanent molds.

Wet soil is compacted inside these tubes, while the cardboard remains in place, forming a supportive shell that enhances soil cohesion , much like a structural embrace that does not separate over time.

Sustainability Derived from Design

The brilliance of this approach lies in its ability to avoid adding complexity or consuming extra resources; it relies on readily available natural materials and reuses them intelligently.

According to Dr. Jiming Ma, the lead researcher on the project, traditional rammed earth construction techniques usually require adding cement to the mixture for durability.

However, this new solution demonstrates that the natural thickness of earthen walls provides sufficient strength without these polluting additives.

Reducing Carbon Footprint and Cost Together

By replacing cement with cardboard, the team was able to reduce the carbon footprint to one quarter of that of traditional concrete, while lowering costs to less than one third.

The numbers clearly demonstrate the effectiveness of this innovation:

- A single column made of CCRE produces only 17.41 kg of CO₂ equivalent.

- In contrast, a conventional concrete column produces about 77.95 kg.

This significant difference reflects not just an improvement in efficiency, but a radical shift in the philosophy of sustainable construction.

Ease of Implementation and Simplicity of Concept

The production process of CCRE is remarkably simple and easy to apply in the field.

Instead of relying on factories or complex equipment, construction teams can produce the material directly on-site.

All that is required is to compact a mixture of soil and water inside cardboard tubes, either manually or using simple equipment, making the process fast and feasible under various conditions.

Local Materials and Avoiding Heavy Transport

Professor Yi Min “Mike” Xie points out that this technique significantly reduces the need to transport tons of traditional construction materials such as bricks, steel, and concrete.

Builders only need lightweight quantities of cardboard, while the rest of the materials can be sourced locally from the surrounding environment.

This feature alone makes the system more efficient and sustainable, while also reducing emissions from transportation and supply chains.

An Opportunity for Remote Areas

This development represents a radical shift in construction philosophy, especially for remote or resource-limited regions.

In areas with abundant red soil , one of the most suitable types for rammed earth construction , this technique can be applied easily, opening the door to sustainable and low-cost infrastructure in rural and remote locations.

Unexpected Strength from a Simple Material

At first glance, cardboard may not seem capable of bearing heavy weights or high pressures; however, experiments have proven otherwise.

The RMIT University team developed a precise engineering formula that predicts the amount of force CCRE can withstand, based on the thickness of the cardboard tubes used in construction.

This approach allows components to be designed with accuracy, ensuring a balance between rigidity and flexibility without the need for costly or polluting additives.

Test Results Confirm Efficiency

After 28 days of natural drying, compression tests showed that CCRE possesses structural strength comparable to cement-reinforced rammed earth.

While it does not match conventional concrete in terms of hardness, it is entirely sufficient for low-rise buildings, such as small houses and community buildings, making it a practical and realistic choice for sustainable construction projects.

Thermal Comfort and Environmental Efficiency

One of the often-overlooked advantages of this type of construction is its natural ability to regulate temperature and humidity inside the building.

Thanks to the high thermal mass of earthen walls, these buildings maintain moderate coolness in summer and relative warmth in winter.

This natural regulation reduces dependence on mechanical heating and cooling systems, leading to lower energy consumption and carbon emissions in the long term.

Practical Applications and a Future Vision

The RMIT team envisions CCRE as an ideal option for constructing low-rise houses, community buildings, and off-grid projects.

It aligns with the global shift toward earth-based construction, which is gaining momentum due to net-zero goals and the desire to use local, sustainable materials that reduce environmental impact.

Turning Waste into Construction Value

The brilliance of this innovation lies in transforming waste into an effective building component.

By combining reused cardboard with soil, the project demonstrates that sustainability does not conflict with efficiency or cost-effectiveness.

Construction materials can be greener, cheaper, and easier to produce simultaneously if we rethink how they are designed and utilized.

Towards Wider Industrial Application

The team is currently seeking to collaborate with industry partners to scale up the production of CCRE and apply it in real-world projects on a larger scale.

The project offers more than just a new material; it presents a completely different approach to sustainable construction.

It serves as a reminder that true innovation does not always mean inventing something from scratch; sometimes, it lies in reviving old techniques with a contemporary vision that makes them more aligned with environmental and future requirements.

✦ ArchUp Editorial Insight

There is no doubt that the CCRE project offers innovative and promising ideas in the field of sustainable construction, particularly regarding the use of local resources and the reduction of carbon footprint. The ability to transform soil and cardboard into a practical building material for low-rise structures represents an exciting step that could inspire architects and urban planners to rethink traditional construction techniques and adopt environmentally friendly solutions in certain contexts.

However, several aspects require careful consideration before this technology can be widely adopted. While the structural strength of the material is sufficient for low-rise buildings, it may limit its application in multi-story buildings or structures that require high resistance to earthquakes and strong winds. Additionally, reliance on local soil and treated cardboard makes the project geographically and environmentally constrained, as material properties may vary significantly from one site to another, necessitating thorough testing for each case before implementation.

On the other hand, practitioners in architecture can benefit from this project as a model for experimentation and learning, integrating non-traditional materials in innovative ways and linking them to environmental design strategies such as natural thermal regulation and energy reduction. With further development and research, the project could become a complementary or optional solution for small-scale and community projects, rather than a full replacement for conventional materials in all contexts, thereby promoting flexible and balanced thinking in architectural sustainability.

Prepared by the ArchUp Editorial Team

Don’t miss the chance to explore more from Architecture in fields like Buildings and Building Materials on the ArchUp website.