Insulation helps protect the building from external temperature and sound. By installing insulation in buildings, heating and cooling loads are significantly reduced, thus reducing energy loads and costs.

Insulation refers to a lower rate of heat transfer into buildings, and it also helps achieve a state of human comfort.

The transmission of sound can be in two ways – impact and sound transmitted through the air.

Acoustic effect- results from the direct impact of the building fabric, which transmits sound through the structure.

Airborne Sound – Sound is transmitted from equipment and the human voice, and the sound of air is associated with the mass of the wall.

The decrease in acoustic power passing through a building element is expressed in decibels (dB).

Insulating materials in interior design

foam concrete

It is a fire and frost resistant material.

It can be easily applied without pressure.

Suitable for insulating floors and flat roofs.

Gypsum paste

Gypsum boards are lightweight walls.

The use of two layers of gypsum board (different thicknesses) reduces sound transmission, as they resonate at different frequencies.

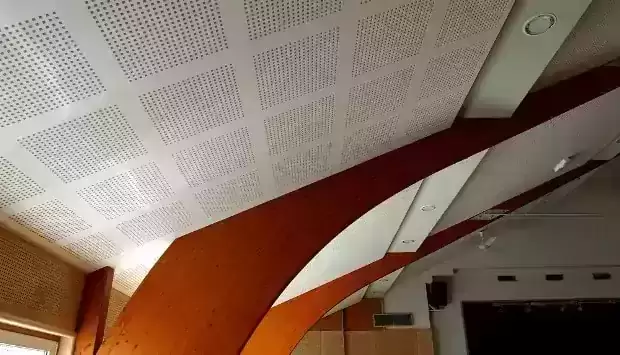

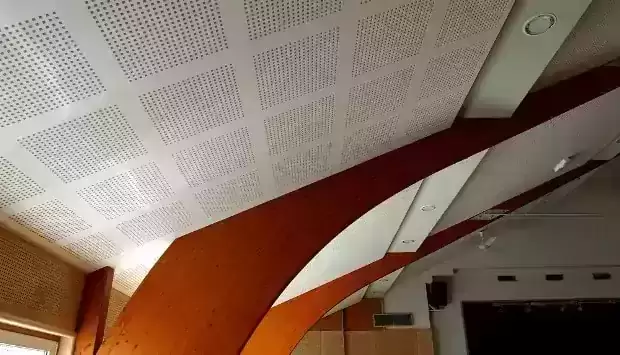

Wood wool boards

Wood wool boards are made from wood fibers and cement. Since it is composed of cement, it is resistant to fire and mold.

It has good sound-absorbing and insulating properties, due to the open sealed surface, along with load-bearing properties.

Mostly used as ceiling decorating materials.

Mineral wool

Mineral wool is made from volcanic rock (silica, alumina and magnesium oxide) mixed with coke and limestone and smelted at 1500°C in a kiln.

It is made into fibers and coated with waterproof resin and mineral oil, then pressed and cured, and cut into finished products in rolls or sheets.

It is non-combustible, water repellent, rot resistant, and contains no CFCs or HCFCs.

They are available in various forms – bulk, mats, batts, semi-rigid panels, solid panels, resin-bonded panels, weather-resistant panels, pre-coated panels, and roof tiles.

Used for cavity grouting, lofts, floor and ceiling insulation, exterior cladding, roof tiles, etc.

Effective in reducing sound transmission.

glass wool

Glasswool is made by a crowning process similar to manufacturing glass wool.

It is non-combustible, water repellent, rot resistant, and contains no CFCs or HCFCs.

They are available in various forms – loose, rolls, bats (solid and semi-solid), etc.

It is used as a filler in cavities, ceilings, floors, interior walls and ceiling tiles.

Cellularity of foam glass blocks

It is made from a mixture of crushed glass and fine carbon powder, which, when heated to 1,000°C, oxidizes the carbon, causing bubbles to form within the molten glass.

The glass is cooled and cut to size.

It is durable and easy to work with, has high compressive strength.

It is non-combustible, waterproof due to its closed cell structure, and contains no CFCs.

Suitable for roof insulation, including green roofs and rooftop parking lots, also for floor insulation and wall cavity grouting.

Exfoliated vermiculite

Manufactured by heating fine natural metal, the material contains 90% air by volume.

Use as loose padding for loft insulation.

Also used as fire stop seals.

expanded perlite

Expanded perlite is manufactured by heating natural volcanic rock minerals.

It is used for loose and on-site bonded insulation for roofs, ceilings, walls and floors as well as preformed panels.

Calcium silicate

It is durable and has good impact resistance.

The wall panels are made of calcium silicate board.

Aerogels

It is a hydrophobic amorphous silica material.

Very lightweight and highly breathable

Innovative paint and coating systems in interior design