Examples of 3D printed homes

Examples of 3D printed homes,

Examples of 3D printed homes

BIOHOME3D

.

East 17th Street Residences

House 1.0

House zero

See More: The tallest buildings in the world promote sustainable development of skyscrapers

Examples of 3D printed homes,

See More: The tallest buildings in the world promote sustainable development of skyscrapers

Interior design aficionado and writer, exploring the interplay of aesthetics, functionality, and personal spaces. Documenting the transformation of interiors and the art of creating ambiance.

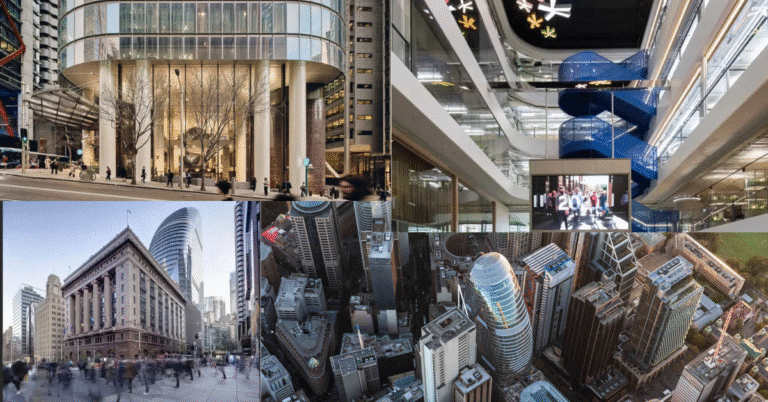

At the heart of Sydney, the 1 Elizabeth Tower stands as a new architectural landmark that bridges heritage with modernity. Rising directly above Martin Place Station, the tower forms a vibrant intersection between urban movement and open public space.A Design…

It is not wrong to say that windows are the eyes of the house, and they give an aesthetic and attractive appearance to the house.It is important to choose the right size of the window because it is not easy…

Historic architectural model “Roman structure” redirects right here. For the structure of the town, see Structure of Rome. Historic Roman structure adopted the exterior language of classical Greek structure for the needs of the traditional Romans, however was totally different…

Introduction: What is the Venice Charter?The Venice Charter of 1964 is one of the most influential international documents concerning the conservation and restoration of historic sites and monuments. It was adopted during the Second International Congress of Architects and Technicians…

The fate of portability is two-haggled to be shared; that is if the new blast of e-bikes on the scene is an absolute necessity. Offering a clamor and emanation free option in contrast to conventional methods of transportation; it has…

Architecture is more than structures—it’s a story, a vision, and a connection to the world around us. At ArchUp, our passion for architecture goes beyond just reporting news; we are here to celebrate design, creativity, and the architects shaping the…