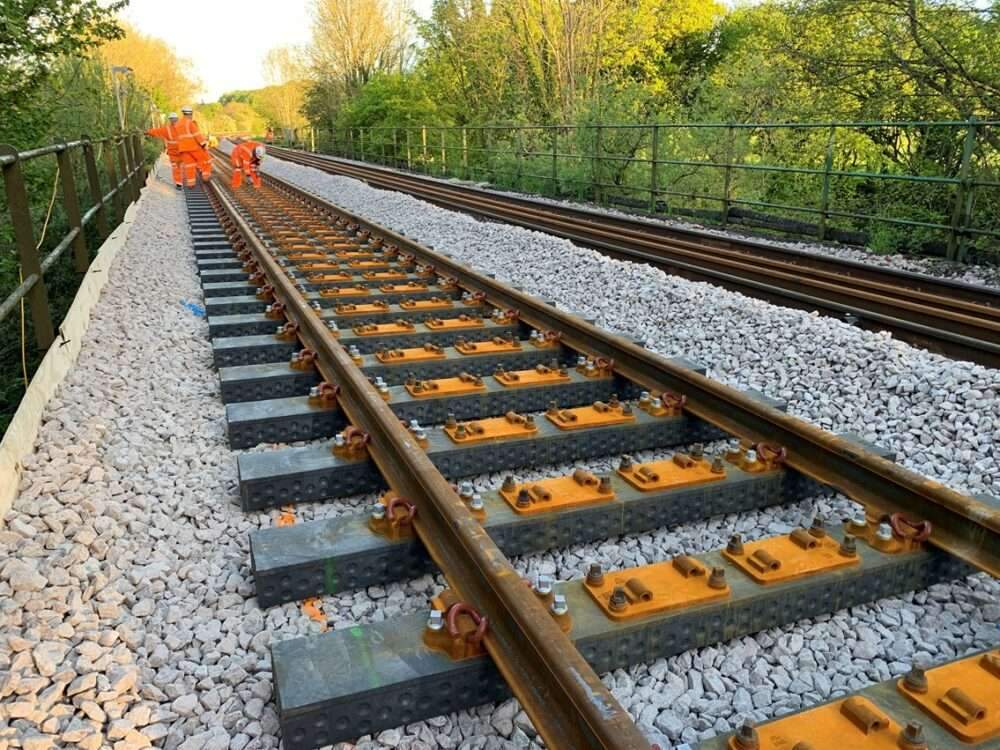

The importance of laying crushed stone in railway tracks

The importance of laying crushed stone in railway tracks,

When it comes to building railway tracks, crushed stone plays a vital role.

It forms the base on which railway tracks are laid and provides a stable base for tracks.

Crushed stone, also known as ballast or track ballast, is used.

To form a stable foundation and provide drainage and support the structure of the railway track.

Crushed stone has been used in railway construction since the early nineteenth century.

Traditional materials such as sand, gravel and soil were used as ballast.

However, they did not provide the stability or drainage required for the structure of the railway track –

the introduction of broken stones allowed the construction of more durable and reliable railway tracks.

Crushed stone comes in different sizes and can be made from different types of materials.

The material is selected based on its characteristics and the needs of the railway track construction project.

For example, some materials may be more suitable for certain geographic locations.

The size and weight of crushed stone are also important factors in choosing the right building materials.

The size and weight of crushed stone are also important factors in choosing the right building materials.

Crushed stone has a variety of advantages over traditional materials such as sand, gravel, and soil.

They are more durable, cost-effective and provide better drainage.

They can also be used in many applications,

from the construction of railway tracks to road pavements and landscaping projects.

The benefits of crushed stone

Crushed stone has been used in the construction of railway tracks for centuries due to its many benefits.

The use of crushed stone is essential to ensure the long-term stability and safety of railway lines.

From increased durability to cost-effectiveness,

There are many reasons why crushed stone should be used in the construction of a railway track.

Durability:

Crushed stone is incredibly durable, which is a huge advantage for railway track construction.

The stones provide superior resistance to elements such as wind, rain and sun, providing a reliable foundation for trails.

Moreover, the stone is corrosion resistant, providing longer life for the tracks.

The stones are also resistant to temperature changes,

which means the tracks will remain strong regardless of the weather.

Cost-effectiveness:

The use of crushed stone in the construction of a railway track is also cost-effective.

Since stones are readily available, the cost of obtaining them is often much lower than other materials.

In addition, the low maintenance cost makes crushed stone ideal for railway track construction.

Drainage:

Crushed stone is also very effective in providing drainage.

The stones are porous, which means that any water from rain or snowfall can be absorbed quickly and efficiently removed from the tracks.

This prevents waterlogging, which can cause significant damage to the rods.

The use of crushed stone in the construction of a railway track is essential to ensure the long-term stability and safety of tracks.

The stones offer many benefits, such as durability, cost-effectiveness and drainage,

making them the ideal choice for building a railway track.

Size and weight of crushed stone

Railway tracks of a certain size and weight were built of crushed stone.

These stones provide the stability and support needed for a safe and efficient railway system.

The size and weight of crushed stone used in the construction of the railway track varies according to the type of railway track being built.

The most common size of crushed stone used in railway track construction is 3/4 inch.

This size is ideal to ensure the track remains stable and safe.

Crushed stone provides a solid foundation for the track and prevents the track from shifting or loosening.

A 3/4-inch size of crushed stone is usually combined with other materials,

such as soil or gravel, to create a more stable and secure foundation for the path.

Another size of crushed stone used in railway track construction is 1/2 inch.

This size is ideal for creating a safer path.

The 1/2-inch size of stone helps create a stable and secure track bed, further helping to prevent lane change or movement.

The 1/2-inch stone size is also used to fill holes and dips at the base of the track.

In addition to size, the weight of the crushed stone used in the construction of the railway track is also important.

The weight of each volume of crushed stone varies. Generally, crushed stones with a size of 3/4 inch weigh about 1.5 tons per cubic yard.

On the other hand, those with a size of 1/2 inch weigh about 1 ton per cubic yard.

The weight of the stones is an important factor to consider when constructing a railway track,

as it helps to ensure that the track remains stable.