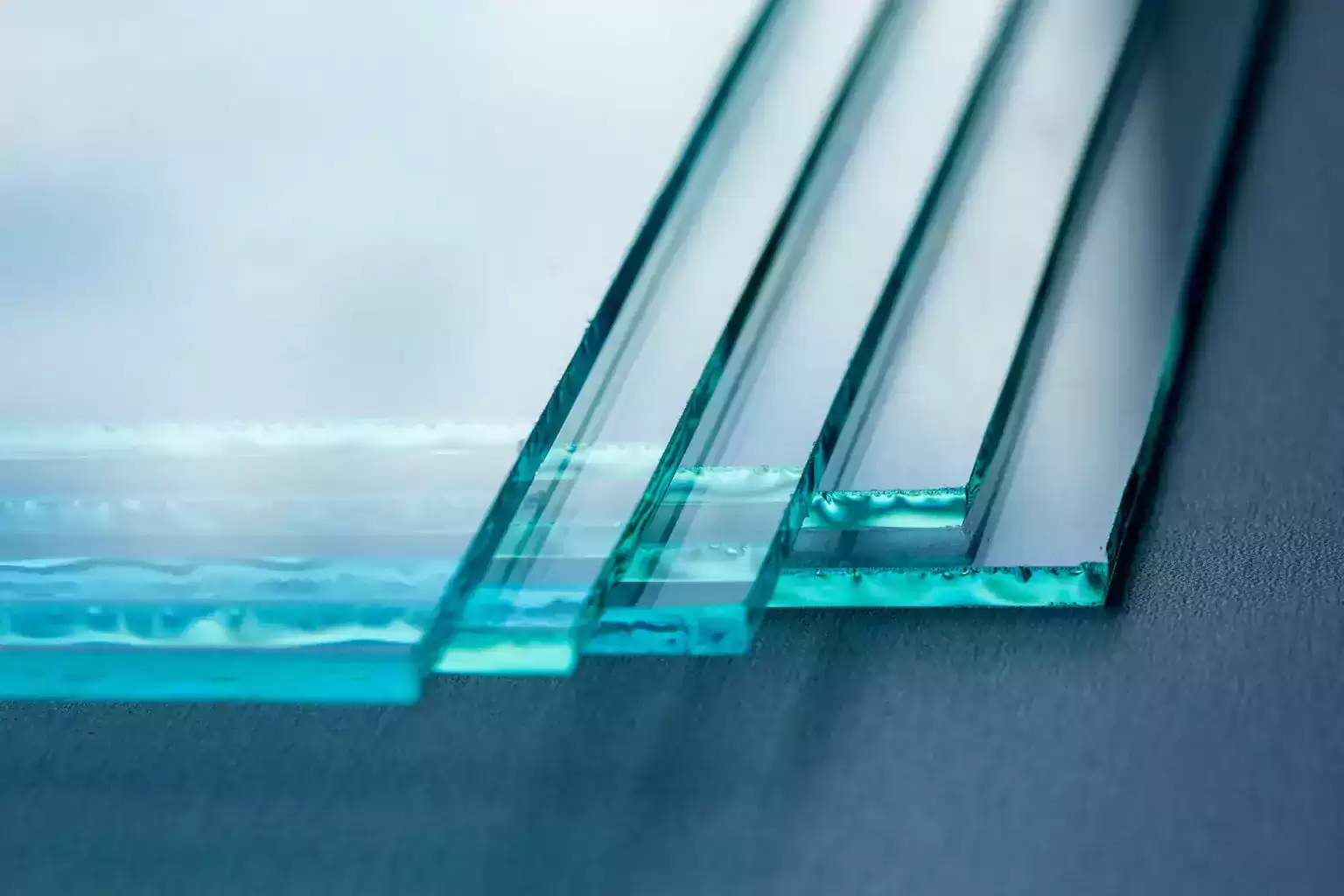

Different types of glass are used in the building industry, for a wide range of purposes.

In addition to its more obvious function as windows,

glass is routinely used in stairways, doors, skylights, sheer ceilings, interior curtain walls, and more.

The type of glass used depends on the specific needs of each project,

and technological advances have expanded the possibilities almost unimaginable.

The basic ingredients (mainly silica, lime and soda) can be combined with different additives to achieve different qualities depending on the job.

Below is a brief overview of the different types of glass used in construction today

Most windows nowadays are made of float glass, and in the process,

the basic components are melted and floated on a layer of molten tin.

The material gradually hardens into the uniform sheets we are all familiar with,

then is annealed or heat treated to remove stresses and increase stability.

But that’s just the beginning, as additional processes and materials provide the versatility that makes glass so useful in a range of settings:

Tempered glass

Tempered glass, also known as toughened glass, is made by rapidly heating molten material to over 1,000 degrees Fahrenheit.

Then quickly cooled to room temperature, the resulting product is four times stronger than ordinary annealed glass.

It also has another benefit that when it does break, the tempered glass separates into small,

grainy pieces rather than sharp-edged shards.

This is one of the reasons why it is used for side windows and rear windshields in cars.

Also, the unique chemical properties of tempered glass make it easy to mold into different shapes.

The tempering process produces optical distortion,

so tempered glass is not preferred when clarity and transparency are important.

Heat strengthened glass

The process for making heat-strengthened glass is similar to that of tempered glass,

except that it cools much more slowly.

The resulting product is twice as strong as ordinary annealed glass, so it has some of the strength of tempered glass,

but without the optical distortion.

This makes heat-strengthened glass the best choice for windows in tall buildings,

which must be able to withstand high winds, while still providing optical clarity.

Shatterproof glass

To make the glass virtually unbreakable, a plastic resin called polyvinyl butyral (PVB) is added during the manufacturing process.

This makes the material more solid without compromising on aesthetics,

as it is visually indistinguishable from regular glass.

Its strength makes it desirable for floors, stairs, balustrades, skylights, and windows.

Laminated glass

An obvious way to increase the strength of glass is to fuse two layers together,

which is what is done with laminated glass.

The process also includes PVB – the same resin used in the production of shatterproof glass.

In this case, a layer of PVB is placed between the two glass panes (the sections),

and the composite unit is heated and pressed to produce a product of exceptional strength.

Different types of glass (heat-strengthened, toughened, clear, tinted, reflective, etc.) can also be laminated to achieve different goals.

And by varying the thickness and color of the PVB plate, the glass can reduce glare or block ultraviolet rays.

And when laminated glass breaks, the particles tend to stick to the PVB rather than falling off or flying off.

These unique qualities make laminated glass ideal for certain uses.

For example, the windshield of a car is made of laminated glass.

It is also used in skylights, pitched glazing, burglar proofing, and soundproofing (such as in music studios).

Bullet-resistant glass is simply several thick layers of glass with sheets of polycarbonate that can absorb the energy of a bullet.

There are of course many other uses for glass in today’s construction industry.

- Glass wool is one of the most effective and widely used insulation materials available today and is available in rolls and can also be sprayed or applied in place.

- Glass block (or glass bricks) are now used in much contemporary architectural design, sometimes to astonishing effect, and have rebounded in popularity since their debut in the Art Deco era.

- Tinted glass can provide aesthetically pleasing effects without compromising other important qualities of glass, as the resulting product is particularly useful for reducing light and heat transmission.

- Ultra clear glass transmits 92% of sunlight without distortion, making it ideal for displays, museum cases, picture windows and other situations where clarity and true color transmission are important.

Since glass is an integral part of almost all construction projects, it helps to know the different types and their uses.

Glass plate sizes

600 x 900 mm

900 x 1200 mm

900×1500 mm

1200 x 1800 mm

1200 x 2100 mm

For more architectural news