WPC sizes of plywood alternative

WPC sizes of plywood alternative,

Plastic wood panel is an exceptional solid and safe material used for construction purposes.

It is a mixture of wood fibers / wood flour and thermal plastics.

WPC panels are also ready of inorganic nap and plastic compounds.

Likewise, plastic and wooden materials are used as a first degree alternative, and a solid cover.

Wood and plastic doors are used for surfaces, fences, floors, bars, doors, landscape windows,

internal and external cladding, to collect entrance tires and windows, to plan solid and designed structures, mixing floor furniture, etc.

In the advanced period, and given the progress of innovation and exploration constantly,

new materials appear in construction work, which is no exception.

One of these materials in construction works is the wood and plastic compound (WPC),

which is an environmental material that appears as an option unlike natural wood and plywood.

It is a complex material that includes wood fibers and thermal plastics,

and WPC panels are mixed to frame a basic material with a thick texture.

Then it is expelled at this point and formed in the different shapes and sizes required.

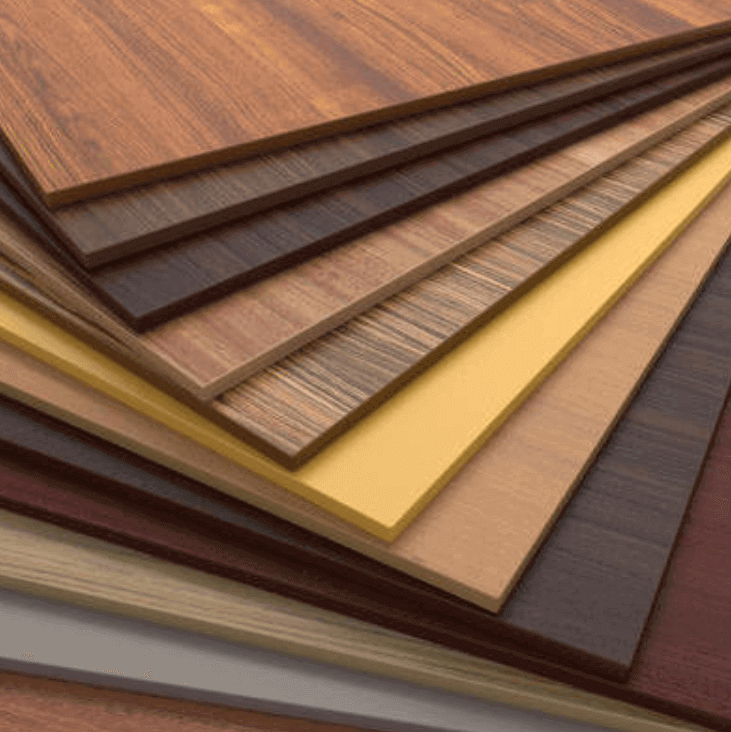

Some distinct shades and additions can also be added to make materials with better details.

There is a variety of functions and applications for WPC panels on external surface floors, window tires, entrances, fences, external scenes, etc.

In terms of average, it contains 70% virgin polymer, 15% wood powder (fiber) and excess additions 15%.

WPC sizes of plywood alternative

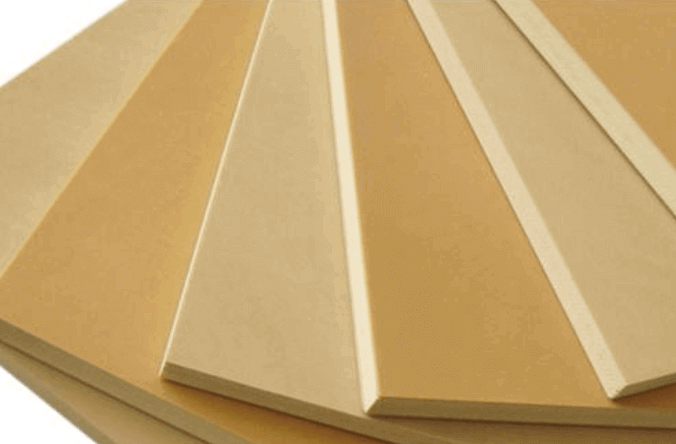

Plastic wood plastic board is available in sizes of 2440 mm x 1220 mm, i.e. 8 x 4 feet with thickness of 18 mm (0.71 inches),

And 17 mm (0.67 inches), 12 mm (0.47 inches), 11 mm (0.43 inches)),

7.5 mm (0.30 inches), 6 mm (0.24 inches), 5 mm (0.20 inches).

WPC boards features

- The shape and appearance resemble natural wood, as the compound plastic wood plate requires lower repair and maintenance, because it is not deformed, crushed or divided into small pieces like natural.

- It is exceptionally objectionable to moisture, and therefore it is a very hard material.

- It also protects from termites and fungi.

- Do not consume effectively and do not collapse or lose their components.

- . Since it is made of redressed plastic and wood residue, it is a feasible and green material.

- There is a merited obsession with nails, screws and fasteners when used with the plastic wood compound contrasting with natural wood.

- It acquires existence everywhere because it is away from cutting the trees in excess of need and is manufactured by waste in a very valuable way to make more sophisticated building materials.

Uses of WPC panels

- External floors: Plastic wood plastic board is exceptionally used on surfaces and external balconies.

WPC makers offer a variety of surface options, such as the solid surface, mosaic surface and hollow surface.

- The fence: the material is durable and protected. It is widely used to arrange fences for gardens and different purposes of external fences.

- The tablet: This material is very strong, and since it can be accessed by a larger size, this allows the use of this substance in the internal and external panels.

- Interior spaces: Plastic panels are also used in the interior to make different things of furniture,

For example, cabinets, bathrooms, interior cutters, and kitchen cabinets, moreover on the roof of the room.

For more architectural news