The World’s Largest 3D-Printed Interior: A Sustainable Transformation in Modern Architecture

Introduction

The construction sector is rapidly evolving with the adoption of 3D printing technologies in architectural projects.A remarkable example is the world’s largest 3D-printed restaurant interior, which takes a sustainable architectural approach to turn recycled plastic into functional and aesthetic spatial elements.D-Printed Restaurant Interior reflects the growing integration of sustainability and advanced technology, paving the way for future innovations in commercial space design.

Project Details

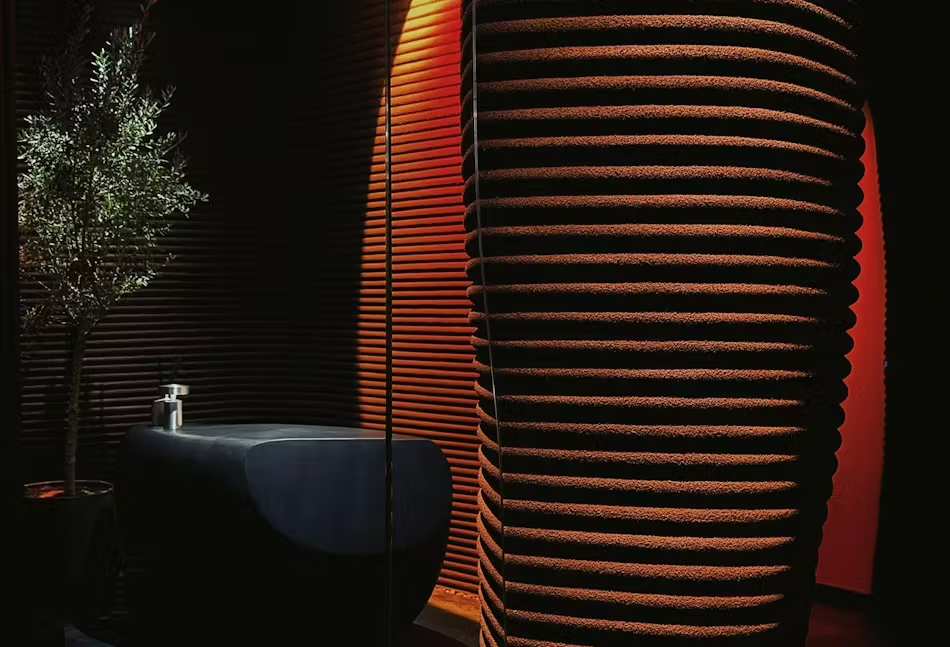

The design team created the restaurant’s interior using 27 canyon-like formations, assembling them from over 20,000 3D-printed components with 35 3D printers.The designers used recycled plastic and textured finishes to create this unique 3D-printed restaurant interior, enhancing the space’s geological depth with natural rock-like formations.

Design and Engineering Aspects

- Geological-Inspired Design: The interior emulates natural canyon formations, using fluid, organic shapes to create a sense of seclusion and immersion.

- Environmental Interaction: The entrance of the D-Printed Restaurant Interior is designed as a narrow passage leading into a spacious lounge, mimicking the experience of entering a natural cave.

- Lighting Techniques: A soft amber glow highlights the architectural details, with artistic lighting effects enhancing the visual experience and atmospheric depth.

Environmental Impact and Sustainability

The project contributes to reducing reliance on traditional materials by utilizing recycled plastic, minimizing waste and carbon emissions. This aligns with regional construction goals, which aim to cut emissions by 8.8 million tons annually by 2030 through advancements in materials and technologies.

The Future of 3D Printing in Construction

- Scalability: 3D printing allows for the creation of large-scale architectural elements, opening the door for more complex multi-storey projects, such as a D-Printed Restaurant Interior.

- Efficiency: Reduced material waste and faster construction times compared to traditional methods.

- Customization: The ability to produce unique and functional designs tailored to specific aesthetic and structural needs.

Summary Table

| Feature | Details |

|---|---|

| Number of Printed Components | Over 20,000 |

| Number of 3D Printers Used | 35 |

| Material Used | Recycled plastic |

| Design Concept | Canyon-like formations inspired by geological structures |

| Environmental Impact | Reduced emissions and enhanced sustainability |

| Key Technologies | 3D printing, advanced coatings, interactive lighting |

Conclusion

This D-Printed Restaurant Interior project highlights the growing role of 3D printing in reshaping architectural landscapes, offering more sustainable and efficient building solutions. As this technology evolves, the construction industry will adopt smarter and more adaptive building practices.