Beijing Daxing International Airport The Organic Metropolis of Air Travel

Introduction and Strategic Vision: A Gateway to Global Ambition

The Necessity of a Mega-Hub and Urban Integration

Beijing Daxing International Airport (PKX) is more than just an airport; it acts as an economic catalyst and a symbol of China’s global ambition. Located 46 kilometers south of central Beijing, the project needed to address saturation at the existing Beijing Capital Airport (PEK). Consequently, it served the immense travel demands of one of the world’s largest metropolises. The scale of the Project required early coordination with Cities and local governments. This ensured its seamless integration into the region’s existing transport network. The airport is designed to anchor the “Jing-Jin-Ji” (Beijing-Tianjin-Hebei) economic triangle, which boosts regional growth and transforms travel across northern China.

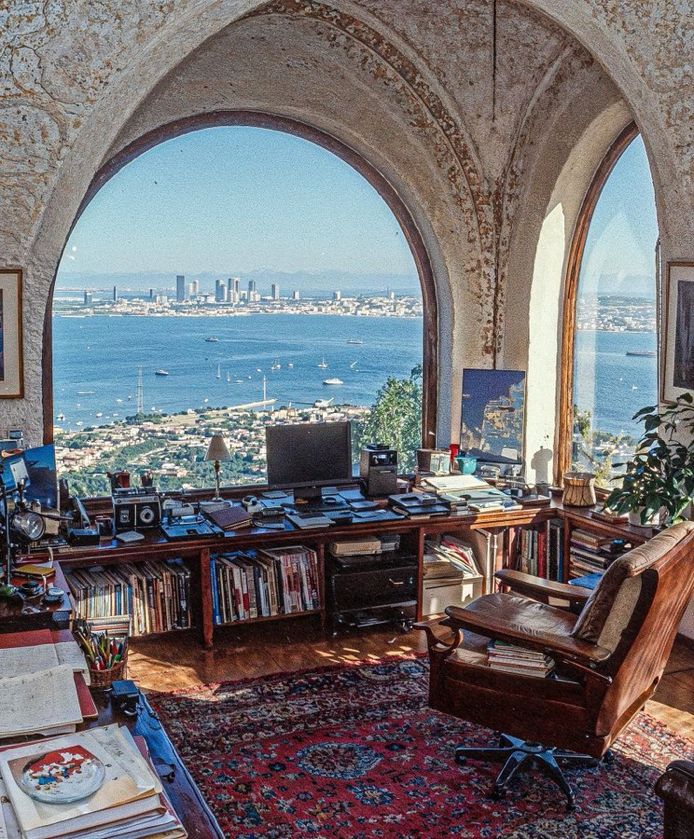

Design Philosophy: Form Follows Flow

Zaha Hadid Architects and ADPI designed the terminal. People often call it the “starfish” due to its distinctive radial shape. This Design is a masterful exercise where form clearly follows flow. The central hub consolidates all services and check-in facilities, and five pier-like arms radiate outwards. The design team aimed to create the world’s largest single-building terminal while minimizing walking distances for passengers. Ultimately, this innovative layout ensures paramount operational efficiency in modern Architecture.

The Organic Structure and Architectural Innovation

The Starfish Terminal: Radial Efficiency

The radial, five-pronged structure ensures passengers arrive directly at the central six-story hub. Connections, retail, and check-in facilities converge here. The distance from the central security checkpoint to the farthest gate is only 600 meters. Therefore, this translates to a maximum walking time of approximately eight minutes a remarkable logistical feat for a terminal this size. Specialized Architectural Research focused on passenger behavior and operational flow directly caused this efficiency.

The Integrated Transport Hub: Subterranean Connectivity

A key innovation exists beneath the main terminal. A dedicated, two-level transport center seamlessly integrates high-speed rail, regional express lines, and the airport subway. This subterranean hub removes the need for separate buildings or long bus transfers. As a result, passengers exit the terminal and immediately access their chosen ground transport. This vertical integration of transit systems is a core feature of the advanced Design and a model for future mega-hubs.

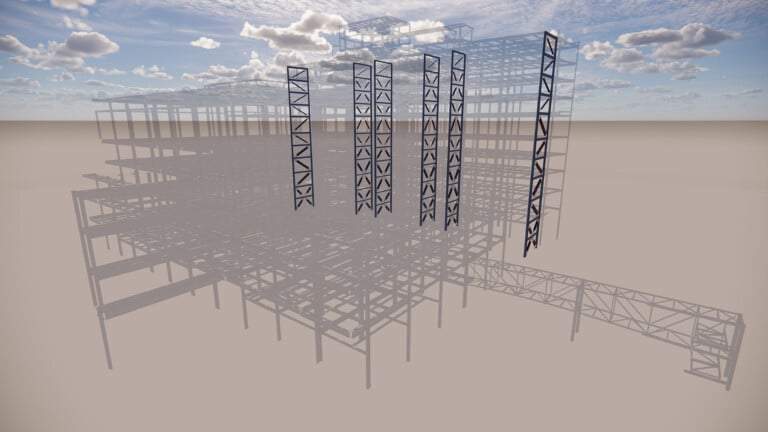

The Free-Form Shell and Structural Mastery

The terminal’s roof is a free-form structural shell that spans a massive area. The structural support system minimizes the number of vertical columns in the main concourse. This enhances the sense of space and allows natural light to penetrate deeply. Just eight C-shaped columns support the entire roof structure. Furthermore, these columns simultaneously direct the downward flow of rainwater and house the MEP (Mechanical, Electrical, and Plumbing) services. This synergy between structural integrity and service integration defines sophisticated Construction.

Engineering and [Construction] Challenges: Scale and Seismic Resistance

The Challenge of Spanning a Vast Area

The terminal building covers over 700,000 square meters. This makes it the largest airport terminal in the world built under one roof. The enormous area demanded highly specialized Building Construction techniques. Specifically, engineers focused on managing thermal expansion and contraction across the massive roof span. Advanced computer modeling calculated structural stress distribution and movement effectively.

Seismic Resistance and Base Isolation

The area experiences seismic activity. Therefore, engineers designed the airport to withstand significant earthquakes. The foundation uses sophisticated anti-seismic technology, including a system of seismic isolation bearings. These bearings effectively separate the terminal’s main structure from the ground. Consequently, they absorb earthquake energy and minimize the forces transferred to the building frame. This commitment to resilience highlights robust Architectural Research in critical infrastructure.

Advanced [Building Materials] and Fire Safety

The roof uses high-performance, self-cleaning glass panels. These maximize natural light but minimize solar gain and the need for artificial lighting—a key Sustainability measure. Fire safety presented a major Construction challenge due to the vast, open-plan concourse. The structural materials, particularly the custom steel grid, were treated with fire-resistant coatings. In addition, engineers designed a specialized smoke control system to work effectively within the expansive space.

| Statistical & Engineering Element | Value | Unit | Executive & Design Significance |

| Terminal Footprint Area | >700,000 | square meters | Largest single-building airport terminal globally, demanding complex Construction coordination. |

| Initial Passenger Capacity (Phase 1) | 45 | million | Passengers per year, reflecting the immediate need for increased capacity in Cities. |

| Ultimate Capacity (Future) | 100 | million | Passengers per year, underscoring the long-term vision of the Project. |

| Maximum Walking Distance (Center to Gate) | 600 | meters | An unprecedented efficiency for a terminal this size, achieved through the radial Design. |

| Number of Support Columns (Central Hub) | 8 | Columns | The minimal number of structural supports enables the open, fluid concourse and maximizes natural light. |

| Total Number of Runways | 7 (4 operational initially) | Runways | Planned capacity to manage over 620,000 aircraft movements annually. |

| Time to High-Speed Rail | <30 | minutes | Travel time from the terminal to the city center via integrated express rail. |

| Design Life of Primary Structure | 100 | years | Commitment to long-term Sustainability and operational resilience. |

Operational Efficiency and [Sustainability] Measures

Minimizing Operational Footprint

The compact radial Design is efficient, not just aesthetic. The design brings the gates closer to the center. Therefore, the terminal needs fewer internal transit systems (like people movers). This reduces both Construction costs and long-term energy use. This centralization optimizes baggage handling and aircraft turnaround times, a critical factor in airport Sustainability.

Smart Systems and Environmental [Design]

The airport integrates numerous “smart” technologies:

- Geothermal Energy: Extensive use of a ground-source heat pump system provides a substantial amount of the terminal’s heating and cooling. This significantly reduces reliance on conventional power.

- Rainwater Harvesting: The vast roof surface collects and filters rainwater. Consequently, the airport uses this water for non-potable purposes, like toilet flushing and irrigation, ensuring greater water Sustainability.

- Natural Lighting: The extensive network of linear skylights reinforces the fluid nature of the Design. Furthermore, it provides daylighting for 60% of the public areas, reducing electricity consumption for illumination.

Conclusion: A Model for Future Global [Architecture]

Beijing Daxing Airport represents a landmark achievement. It shows that monumental scale can combine with unparalleled operational efficiency and elegant Architecture. The airport sets a new global benchmark for transport Projects. This is clear from its complex structural shell and seismic isolation to its integrated transport hub and reduced passenger walking distances. The airport’s commitment to green technology and vast scale makes it a subject of continuous Architectural Discussions worldwide. It secures its place in the history of Architecture Around the World and modern Building Construction.

✦ ArchUp Editorial Insight

Beijing Daxing Airport embodies immense Architectural Ambition and follows a “Form Follows Flow” methodology, utilizing an Organic Style shaped like a “Starfish” to maximize operational efficiency. Structural Innovation is evident in the free-form shell structure, supported by only eight main columns, and the vertical integration of multi-modal transport networks (like high-speed rail and subway) within a subterranean hub. This radial Spatial Dynamic drastically minimizes passenger walking distances, representing a unique logistical success in optimizing Spatial Function. However, criticism centers on the resultant Functional Cost Value; the enormous size of the building necessitated advanced engineering techniques to manage thermal expansion and seismic resilience (via complex base isolation bearings). Furthermore, the challenge of ensuring fire safety within this vast, open space requires specialized and highly costly smoke control systems, thereby increasing the operational and maintenance burden of this colossal Architectural Form.

A deeper Architectural Discussion within modern Architecture explores how innovative Design and advanced Construction methods reshape global Projects in the pursuit of sustainability and human-centered environments.