ColorQuant: a groundbreaking photovoltaic module

In 2022, Merck and Ceramic Colors Wolbring GmbH merged forces to create the ColorQuantTM solar technology, which defies the accepted belief that colored PV modules are less efficient in terms of energy production. We need to8216;step up the use of a photovoltaic module on buildings and other structures, in order to reduce the amount of carbon dioxide produced by fossil fuels. Nevertheless, this often gets overlooked due to the deficiency of color options available. People traditionally veered away from using coloration since it would detrimentally affect the performance of the power system. Luckily, a revolutionary technology has been made available: an interference coloring system. This opens up a variety of new options for designers, architects, and infrastructure masterminds.

In search of an innovative solution

The process of creating ColorQuantTM went through extensive study of various approaches, such as organic coloring, which was not suitable due to its degradation risks, and absorbing pigments, which were inefficient due to light blocking, containing toxic elements, and producing dull colors. The option of interference through dielectric stacks was too complex, light angle sensitive, expensive, and unstable. ColorQuantTM photonic pigments resulted in pure, validated colors that guarantee the longevity of solar performance and color performance. Furthermore, it meets all stability requirements, is user-friendly when integrating into solar modules, and has an impressive price-performance ratio and service life regarding efficiency and quality.

The technological features

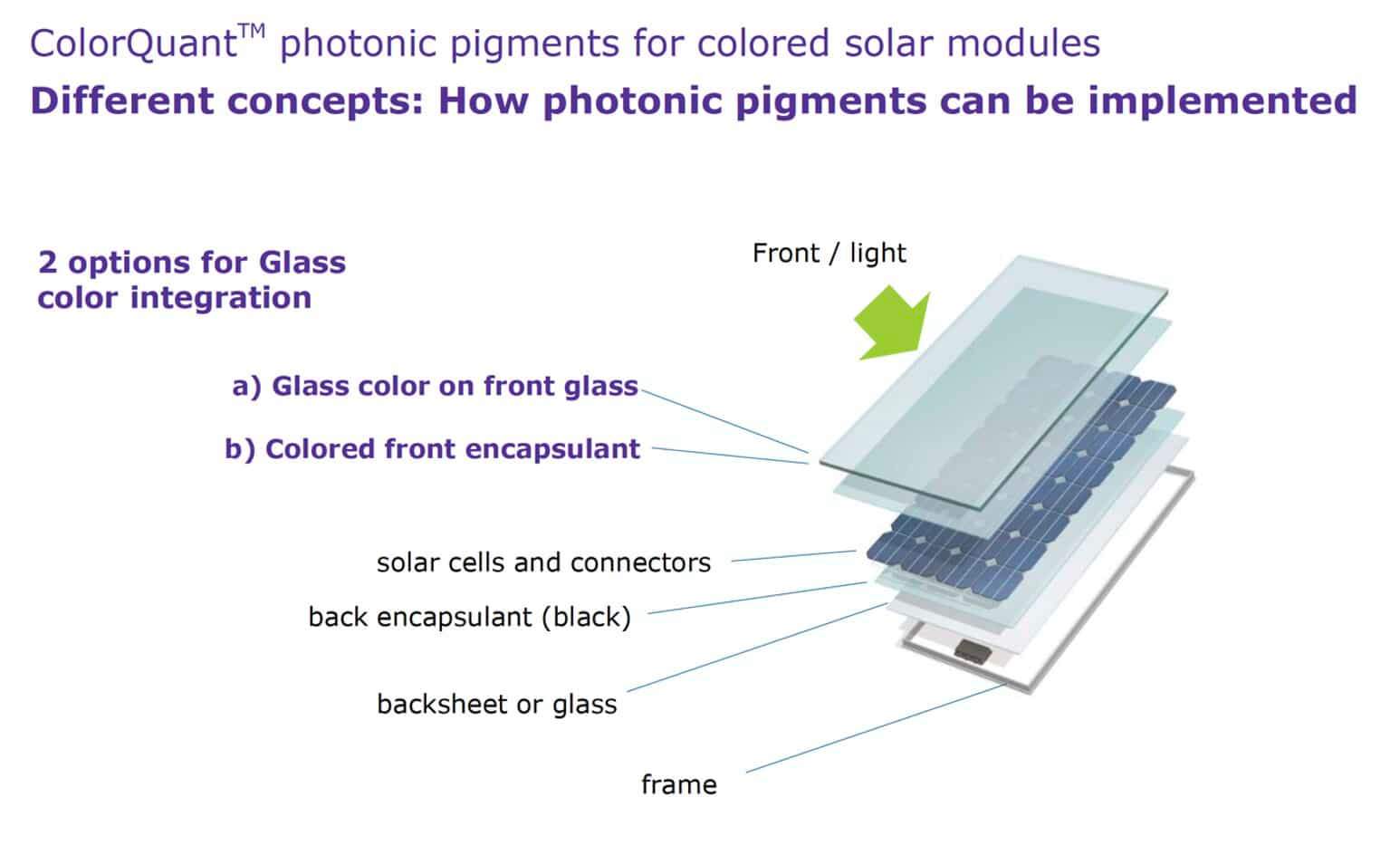

When it comes to incorporating photonic pigments into PV modules, there are various methods of doing so. For example, one can screen print, roller coat, or spray the color onto the front glass of the panel, or place the color into the encapsulant film immediately after the glass. The ColorQuant™ technology used for coloring of solar modules utilizes water-soluble ceramic pastes as pigments, and the color is created through interference of incident sunlight on the inorganic, eco-friendly pigments. This method allows the entirety of the light needed for the solar cell to generate energy to pass through, thus resulting in only a small decrease (ca. 10%) in the module’s power output, while still providing a rich, yet translucent hue. The diagram below shows the structure of a solar panel and how ColorQuant™ fits into the design.

ColorQuant™’s applications

By introducing ColorQuantTM, a massive transformation is set to take place in the use of a photovoltaic module in visually-sensitive architectural and product design. Existing PV roof paneling has – due to its dark colors and limited palette (ranging only from blue to black) – become an unwelcome sight in built environments. Thus far, these applications have principally focused on architectural applications only. However, applications can also be extended to other product categories to open doors to new possibilities for aesthetic integration.

Automotive and transport, lighting, and many outdoor functional structures could all benefit from this untapped potential. With ColorQuantTM, a wide range of colors, as well as translucent finishings, can be made available to designers, thereby offering them more ways to explore product designs and building integration. Specifically, Ceramic Colors Wolbring and Merck joined forces to create ColorQuantTM PV colors to be used for façade-integrated PV elements, thereby opening the door to additional design and production possibilities.

Pros and cons: an objective viewpoint

A technology which has the potential to change the look of renewable energy devices is highly applicable, and even more so since the colors are created with water-soluble, eco-friendly ceramic materials – and so no safety warnings according to EU rules need to be included. This offers glass finishers who work with ColorQuant tones no extra costs for waste clearance due to color leftovers etc., which needs no special disposal arrangements. Although, devising altered colors and outward appearances can’t resolve all struggles of PV employment, e.g. how to extend the accessible backup area or difficulties related to the batteries are the primary challenges.

Who is involved? Players and logistics

To utilize the ColorQuantTM features to its full potential, there must be many stakeholders involved; such as PV panel manufacturers, and glass finishers. Merck ensures that all formats and sizes, up to a massive 3210 × 6000 mm, are correctly implemented. Furthermore, the color palette is monitored and consistent, so that if a replacement were needed, it would be easy to do so. photovoltaic module

Finally, find out more on ArchUp: