Types of structural tube system and its advantages

Types of structural tube system and its advantages,

Structural tube system is a tubular structural system used in tall buildings,

to withstand lateral loads such as wind and seismic forces.

These lateral load-resistant systems allow the building to act like a hollow cylindrical tube cantilever perpendicular to the ground.

Thus the structure exhibits tubular behavior against lateral loads,

and the ducting system was developed by the famous structural designer Fazlur Rahman Khan in 1960.

Khan was the first to use tubular design in structural engineering,

and the DeWitt Chestnut Apartment in Chicago was the first tubular structure designed by Khan in 1963.

Features of the tubular structural system

The tubular structural system evolved from the concept of a rigid frame system which is a three-dimensional frame capable of resisting all lateral loads of the façade structure.

The system consists of an inner basic arrangement surrounded by outer columns,

with the outer perimeter columns close together and connected to each other,

using deep beams that form a rigid frame.

Thus this arrangement creates a dense and strong structural wall along the exterior of the building.

The outer frame is designed to be strong enough to withstand lateral loads on the building,

thus allowing the interior of the building to withstand gravitational loads.

The inner columns are few in number and are located around the main structure.

The base frame and surrounding frames are spanned by beams or struts,

so that these members help transfer gravitational loads into the structure.

This mechanism increases the effectiveness of the circumferential tube to resist overturning moments formed due to lateral loads.

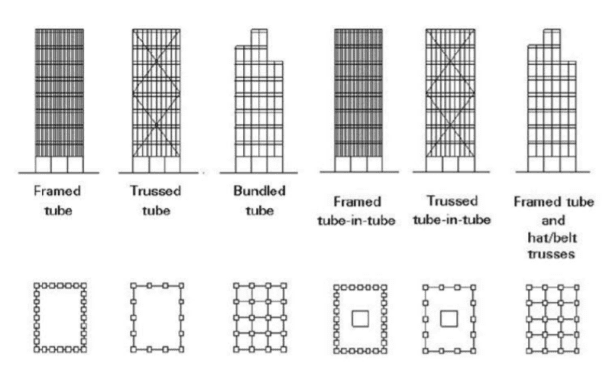

Types of Tubular Structural System

The main types of tubular structural systems are:

- Framed tube system

- Trussed tube system

- Tube in tube system

- Bundled pipe system

- Hybrid tube system

-

Framed tube structure system

It is the simplest and first of the khan’s tubular structural system,

the tube framed can be used for various shapes of floor plan such as square, round, rectangular, and free-form.

The framed tube structural system consists of closely spaced,

rigidly connected exterior columns with deep girders running continuously along each façade and around the corners of the building.

This arrangement increases the rigidity of the beam and shaft by reducing the apparent span dimensions and increasing the depth of the member.

This type is considered the most effective for buildings from 38 to 300 m in height.

Types of structural tube system and its advantages

This arrangement increases the rigidity of the beam and shaft by reducing the apparent span dimensions and increasing the depth of the member.

This type is considered the most effective for buildings from 38 to 300 m in height.

-

Trussed tube structure system

Combined tube structural systems, such as tube frame systems,

consist of fewer external columns than frame tube systems that are set apart.

These columns are connected using steel struts or concrete shear walls.

This connection between the external columns makes the building a solid box capable of resisting lateral shear,

by the axial force in the members rather than bending or arching.

Wide beam spacing in the tapered tube system also allows free window space.

- Tube-in-a-tube structure system

Also known as “structure and body” arrangement, the base tube is surrounded by an outer tube,

and contains the basic elements of a high-rise building such as elevators, canals, stairs, etc.

An outer tube system is the usual tube system that takes the majority of the gravity and lateral loads.

In this system, the inner and outer tubes interact horizontally as shear and bend components.

- Assembled Structural Tube System

In this system there are many tubes interconnected to form a multi-celled tube,

such that this arrangement resists lateral loads and overturning moments.

This system is used in the design of the most economical and multi-use buildings,

which helps to create interesting shapes.

The Willis Tower in Chicago is the first building to adopt the tube-in-tube structural design.

- Hybrid tube structural system

Hybrid structural system is used in the design of thinner or less strong and rigid buildings,

where a hybrid tube structural system combines two or more structural forms in different parts of the structure.

This system is most common in complex building designs.