Bio Based Concrete Absorbs CO₂, Cures in Hours at WPI

WORCESTER, USA – Bio based concrete alternatives that absorb CO₂ during curing have emerged from research at Worcester Polytechnic Institute (WPI). The material reaches 25.8 MPa compressive strength and cures in hours.

Rapid Curing Meets Structural Demand

It hardens fully within hours.

This beats the 28-day standard for Portland cement.

Its 25.8 MPa strength exceeds the 17 MPa minimum for load-bearing uses.

That makes it viable for bricks, panels, and small bridges in construction.

Enzyme Drives Carbon Capture

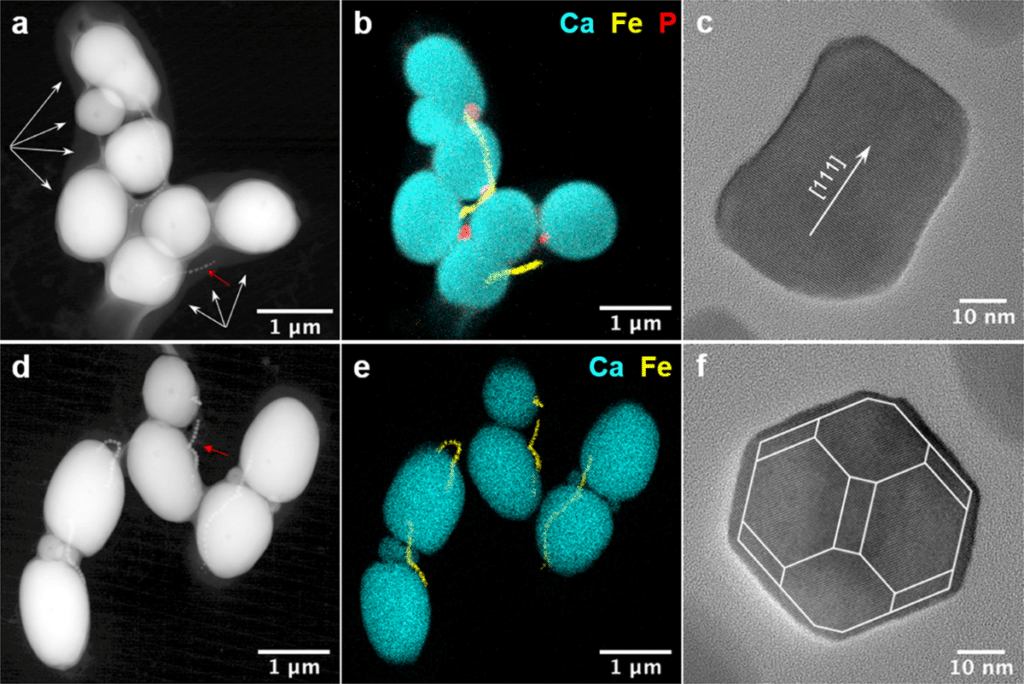

Researchers use carbonic anhydrase an enzyme in human blood.

It converts CO₂ and water into calcium carbonate crystals.

These bind sand into a solid, rock like mass.

The process mimics how coral builds shells.

Unlike conventional building materials, it stores 6.1 kg of CO₂ per cubic meter.

Traditional concrete emits 330 kg.

The team aims for active carbon removal, not just lower emissions.

Cities Could Deploy It Quickly

WPI now tests scalability for urban infrastructure.

The material needs no high temperature kilns.

That cuts energy use significantly.

Its water resistance supports outdoor or wet-environment use.

Planners in cities may adopt it for rapid housing or emergency buildings.

Future results could enter the public archive of carbon sequestering tech.

Updates will appear in news channels.

This work reframes sustainability moving from harm reduction to environmental repair.

It positions bio based concrete alternatives as core tools for next gen material science.

Architectural Snapshot

WPI researchers created an enzymatic structural material with 25.8 MPa strength that cures in hours and sequesters CO₂ advancing the real-world use of bio-based concrete alternatives.

✦ ArchUp Editorial Insight

The article presents WPI’s enzymatic structural material as a carbon negative alternative with technical precision, avoiding promotional language while grounding claims in measurable data like 25.8 MPa strength and CO₂ sequestration rates. Yet it sidesteps deeper questions: Can lab scale biology survive real world supply chains and cost pressures? The narrative leans on regenerative rhetoric without confronting the cement industry’s entrenched economics. Still, the focus on rapid curing for prefabrication is a pragmatic anchor. Whether this innovation fades as another lab curiosity or scales into actual infrastructure depends less on compressive strength and more on policy and procurement not engineering alone.